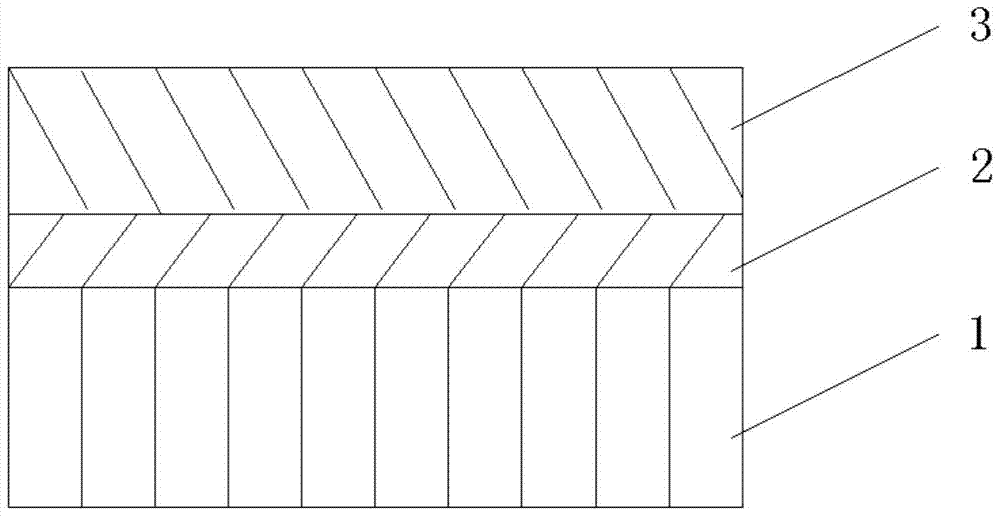

A kind of chemical plating ni-p/ni-mo-p composite structure coating and preparation method thereof

A composite structure, ni-mo-p technology, applied in the field of chemical plating Ni-P/Ni-Mo-P composite structure coating and its preparation, can solve the problems of poor heat exchange performance, pipeline blockage, reduced energy utilization efficiency and the like , to achieve the effect of improving anti-corrosion, improving physics, and improving anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

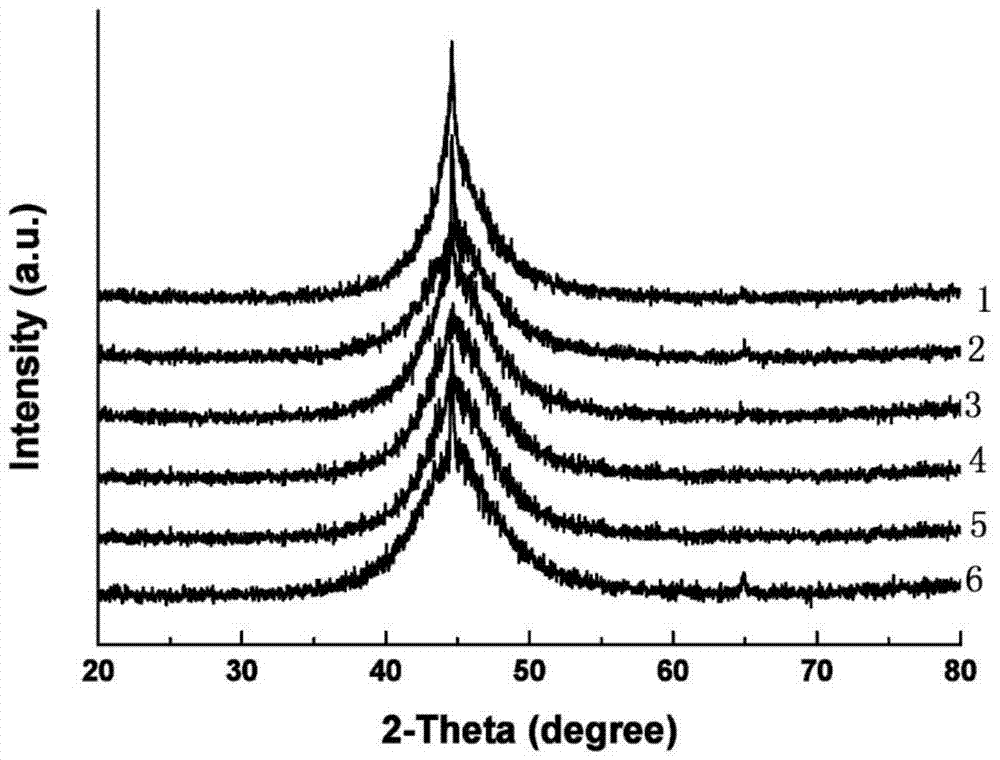

Embodiment 1

[0025] (1) Degreasing and derusting the surface of the metal substrate;

[0026] (2) Polishing the metal substrate after step (1) treatment: the metal substrate is placed in a mixed solution consisting of 50wt% phosphoric acid, 10wt% acetic acid and 40wt% sulfuric acid, placed at a temperature of 60- At 70°C, the soaking time is 2 minutes;

[0027] (3) Plating once: Plating solution A comprises the following components: nickel sulfate 20g / L; sodium hypophosphite 20g / L; citric acid 4g / L; sodium acetate 16g / L; Put the base material in an ultrasonic water bath, then add plating solution A to it, the ultrasonic frequency is 800-1000Hz, and apply plating for 1h;

[0028] (4) Secondary plating: Plating solution B includes the following components: nickel sulfate 30g / L; sodium hypophosphite 10g / L; sodium molybdate 3g / L; citric acid 4g / L; sodium acetate 16g / L; Agent FC-134: 0.1g / L; cerium sulfate 0.5g / L; put the metal substrate treated in step (3) into an ultrasonic water bath, and ...

Embodiment 2

[0033] (1) Degreasing and derusting the surface of the metal substrate;

[0034] (2) Polishing the metal substrate after step (1) treatment: the metal substrate is placed in a mixed solution consisting of 50wt% phosphoric acid, 10wt% acetic acid and 40wt% sulfuric acid, placed at a temperature of 60- At 70°C, the soaking time is 2 minutes;

[0035] (3) Plating once: Plating solution A comprises the following components: nickel sulfate 30g / L; sodium hypophosphite 10g / L; citric acid 6g / L; sodium acetate 14g / L; Put the base material in an ultrasonic water bath, then add plating solution A to it, the ultrasonic frequency is 800-1000Hz, and apply plating for 1h;

[0036] (4) Secondary plating: Plating solution B includes the following components: nickel sulfate 20g / L; sodium hypophosphite 20g / L; sodium molybdate 0.1g / L; citric acid 6g / L; sodium acetate 14g / L; Active agent FC-134: 1g / L; cerium sulfate 0.1g / L; put the metal substrate treated in step (3) into an ultrasonic water bat...

Embodiment 3

[0041] (1) Degreasing and derusting the surface of the metal substrate;

[0042] (2) Polishing the metal substrate after step (1) treatment: the metal substrate is placed in a mixed solution consisting of 50wt% phosphoric acid, 10wt% acetic acid and 40wt% sulfuric acid, placed at a temperature of 60- At 70°C, the soaking time is 2 minutes;

[0043] (3) Plating once: Plating solution A comprises the following components: nickel sulfate 25g / L; sodium hypophosphite 15g / L; citric acid 5g / L; sodium acetate 15g / L; Put the base material in an ultrasonic water bath, then add plating solution A to it, the ultrasonic frequency is 800-1000Hz, and apply plating for 1h;

[0044](4) Secondary plating: Plating solution B includes the following components: nickel sulfate 25g / L; sodium hypophosphite 15g / L; ammonium molybdate 3g / L; citric acid 5g / L; sodium acetate 15g / L; Agent FC-134: 0.6g / L; cerium sulfate 0.3g / L; put the metal substrate treated in step (3) into an ultrasonic water bath, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com