Semiconductor structure, forming method thereof and field effect transistor

A technology of semiconductors and nitride semiconductors, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that the structure design and preparation methods need to be improved, so as to improve the interface defects, simplify the preparation process and equipment requirements, reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

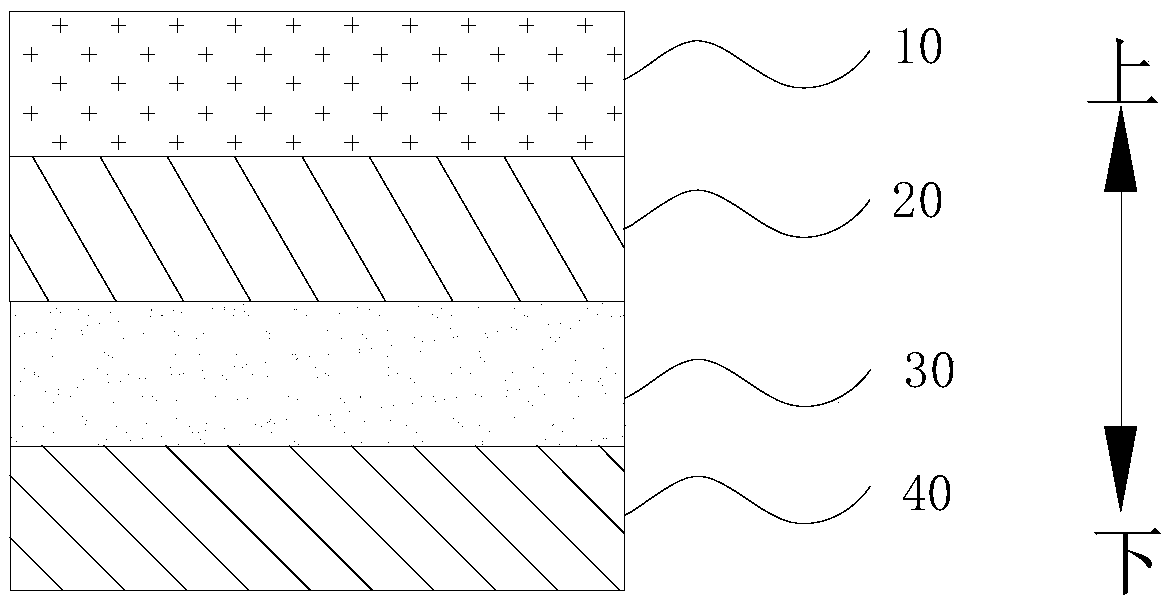

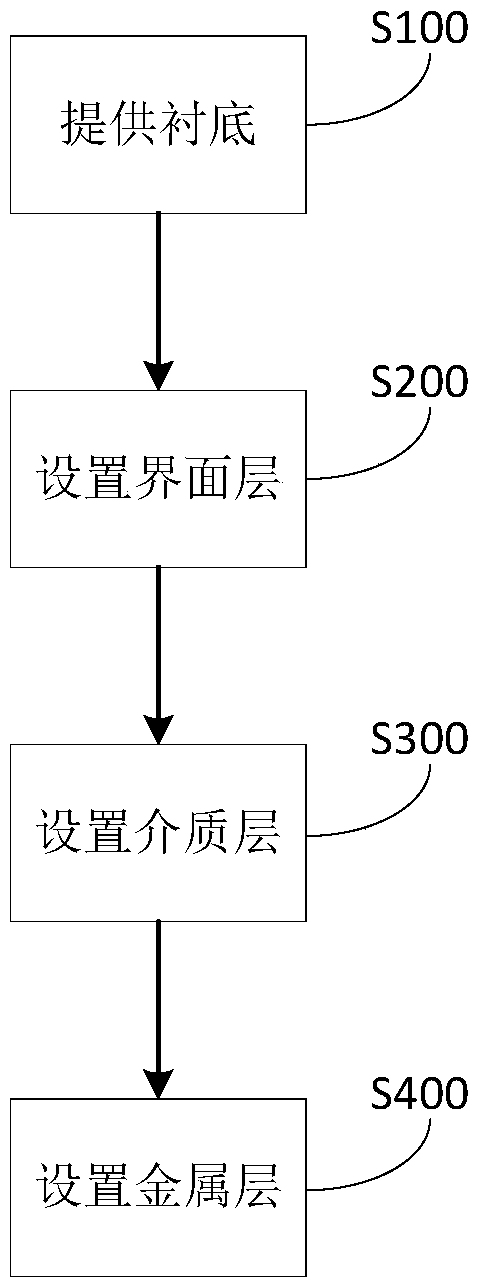

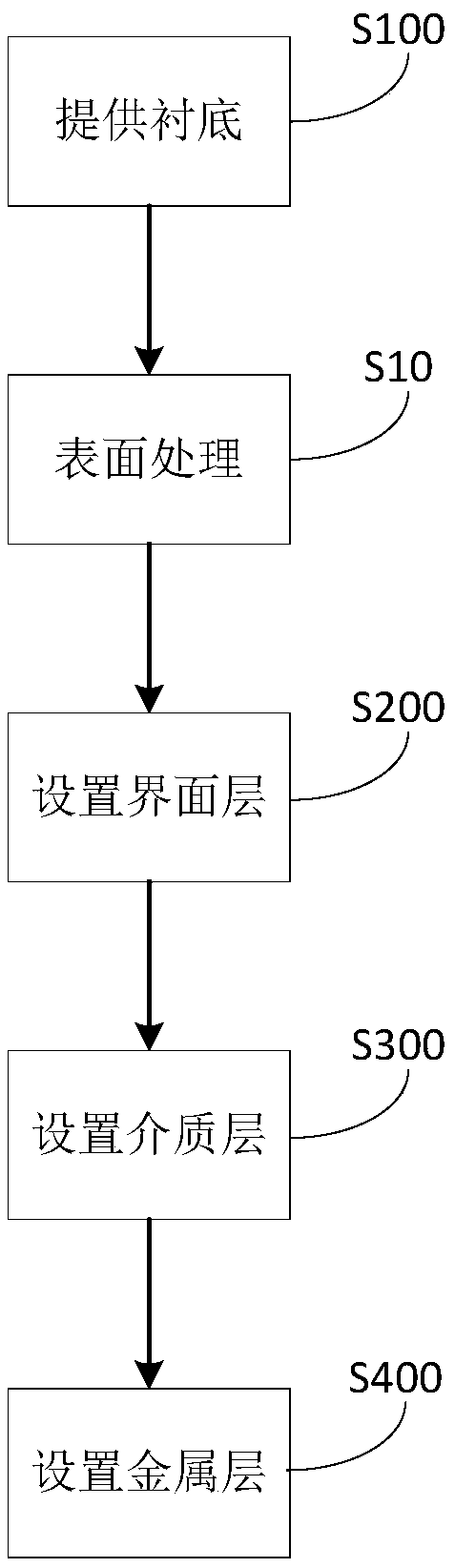

[0070] Embodiment 1 Preparation of GaN substrate semiconductor structure

[0071] A GaN free-standing wafer was chosen as the substrate. In addition, one surface of the GaN self-supporting wafer is a nonpolar m-plane. Concrete preparation process is as follows:

[0072] i. Soak the GaN substrate sample sequentially in acetone and alcohol heated in a water bath at 65 degrees Celsius for 20 minutes.

[0073] ii. Rinse with deionized water for 10 minutes, soak in isopropanol for five minutes.

[0074] iii. Prepare the aqua regia solution, put the aqua regia solution into a water bath at 65 degrees Celsius, and put the GaN sample in the aqua regia for 40 minutes to remove the natural oxide on the surface.

[0075] iii. Rinse the substrate with deionized water for 10 minutes, soak in isopropanol for 5 minutes, and blow dry with nitrogen.

[0076] v. Immediately place the cleaned sample into the ALD chamber for deposition. Aluminum nitride is deposited on the m-plane GaN, and N...

Embodiment 2

[0078] Embodiment 2 Preparation of GaN substrate semiconductor structure

[0079] A gallium nitride free-standing wafer was chosen as the substrate. In addition, one side surface of the gallium nitride self-supporting wafer is a nonpolar a-plane. All the other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com