A kind of preparation method of naphtha isomerization catalyst

A catalyst, isomerization technology, applied in physical/chemical process catalysts, reformed naphtha, molecular sieve catalysts, etc., can solve the problems of high reaction temperature, polluted environment, and corroded equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve chloroplatinic acid containing 0.3 grams of platinum in 6 grams of water, fully mix 10 grams of 200-mesh cellulose with the above solution, and dry the mixture at 80°C for 6 hours to obtain platinum-loaded cellulose.

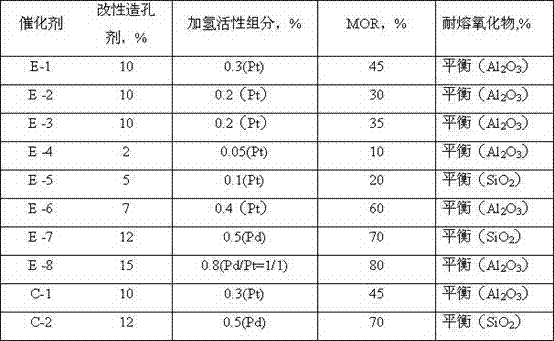

[0027] (2) Fully knead 45 grams of mordenite, 72 grams of aluminum hydroxide dry rubber powder (SB produced by Condean, Germany, 76% on a dry basis), platinum-loaded cellulose, 50ml of 0.2M nitric acid solution and 30ml of water , making it into a paste-like plastic, forming a cylindrical strip with a diameter of 1.5mm on an extruder, drying the cylindrical strip at 110° C. for 8 hours, and then roasting at 650° C. for 4 hours in an air atmosphere to obtain a catalyst product. The pore volume of the catalyst with a pore diameter of 1-10nm accounts for 5.9% of the total pore volume, and the pore volume of 100-1000nm accounts for 55.3% of the total pore volume. The catalyst composition is shown in Table 1, and the evaluation results are shown in...

Embodiment 2~8

[0029] The same as Example 1, the difference is that the types and amounts of various substances in each step have been adjusted, and the composition of the catalyst is different. The catalyst numbers of each embodiment are E-2~E-8, and the pore-forming catalysts used in each embodiment are The dosage and catalyst composition are shown in Table 1, and the evaluation results are shown in Table 2.

Embodiment 9

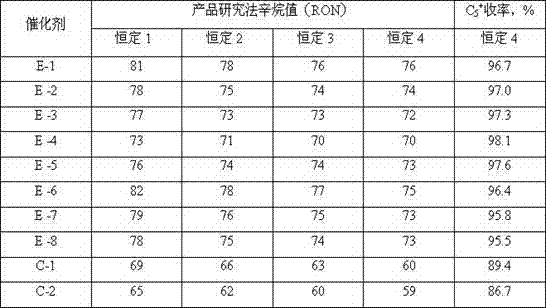

[0035] E1~E8 and C1~C2 were evaluated for catalyst performance, and the evaluation conditions were as follows: take hydrorefined naphtha (RON=53) as raw material, take 20ml of catalyst, dilute with 10ml of quartz sand and fill it into a fixed-bed micro-continuous Catalytic activity evaluation was carried out in the reactor. Before the evaluation, under the conditions of pressure 2MPa and temperature 200°C, pure hydrogen was introduced at a rate of 800 gas volume ratio (the volume of the gas entering to the catalyst loading volume ratio), and after 2 hours, the temperature was raised to 290°C and kept The time is 4 hours for catalyst activation; then the pressure and temperature are constant, the hydrogen hydrocarbon molar ratio is adjusted to 4, and the volume space velocity is 2.0h-1 Enter the raw material, at 290°C, 2.0MPa, volume space velocity 2.0h -1 , Under the condition that the molar ratio of hydrogen to hydrocarbon is 4.0, the reaction is a constant every 8 hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com