Method for preparing boron nitride nanosheet by using eutectic salt to strip boron nitride powder at high temperature

A high-temperature exfoliation and powder preparation technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nitrogen compounds, etc., can solve the problem of uneven size of boron nitride nanosheets and bending deformation of boron nitride nanosheets , high energy consumption in the synthesis process, etc., to achieve the effect of easy operation, simple operation and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing boron nitride nanosheets by exfoliating boron nitride powder at high temperature using a eutectic salt, the method comprising the following steps:

[0036](1) 0.67g pre-dried raw material hexagonal boron nitride (h-BN) micropowder (particle diameter is about 10 microns), sodium chloride and potassium chloride eutectic salt, wherein sodium chloride is 14.87g, chlorine Potassium chloride is 18.47g, joins in the mortar and mixes and grinds, obtains uniform white mixing powder;

[0037] (2) Put the mixed powder obtained in step (1) into a 100mL alumina crucible, then put the crucible into a muffle furnace, and heat the mixed powder from room temperature to 670°C, then keep the temperature for 72 hours for high temperature heat treatment, after the air atmosphere drops to room temperature, the mixed powder after high temperature heat treatment is obtained;

[0038] (3) The mixed powder after the high-temperature heat treatment...

Embodiment 2

[0042] This embodiment provides a method for preparing boron nitride nanosheets by exfoliating boron nitride powder with eutectic salt at high temperature. This method is basically the same as the method in Example 1, except that the high temperature of step (2) The time of heat treatment was changed from 72 hours to 5 hours, and the temperature of high temperature heat treatment was unchanged.

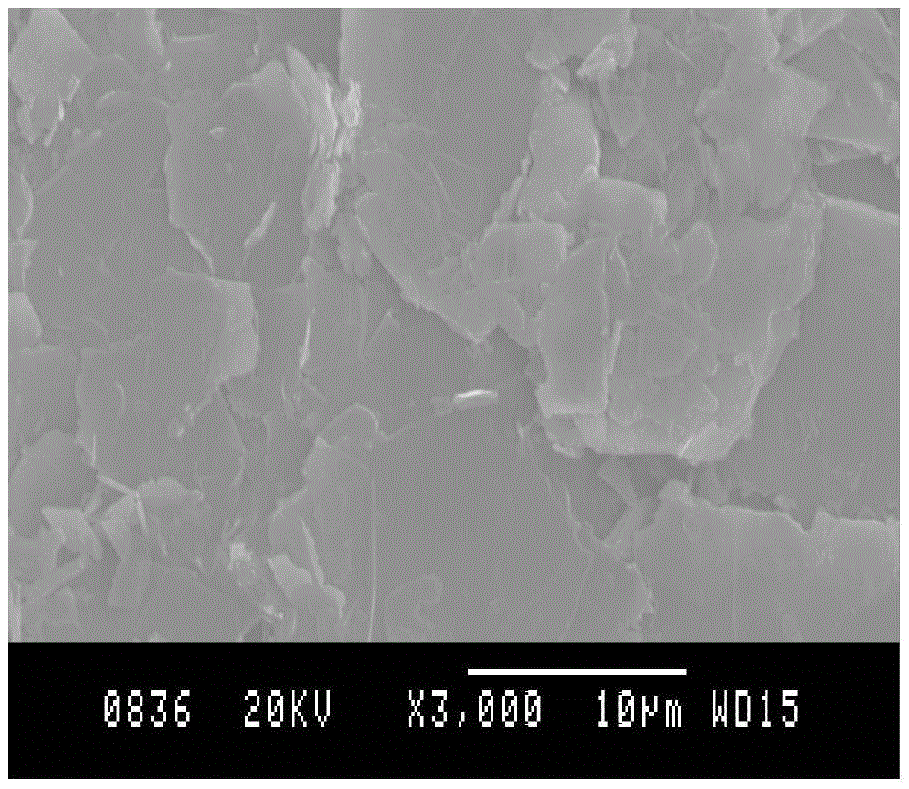

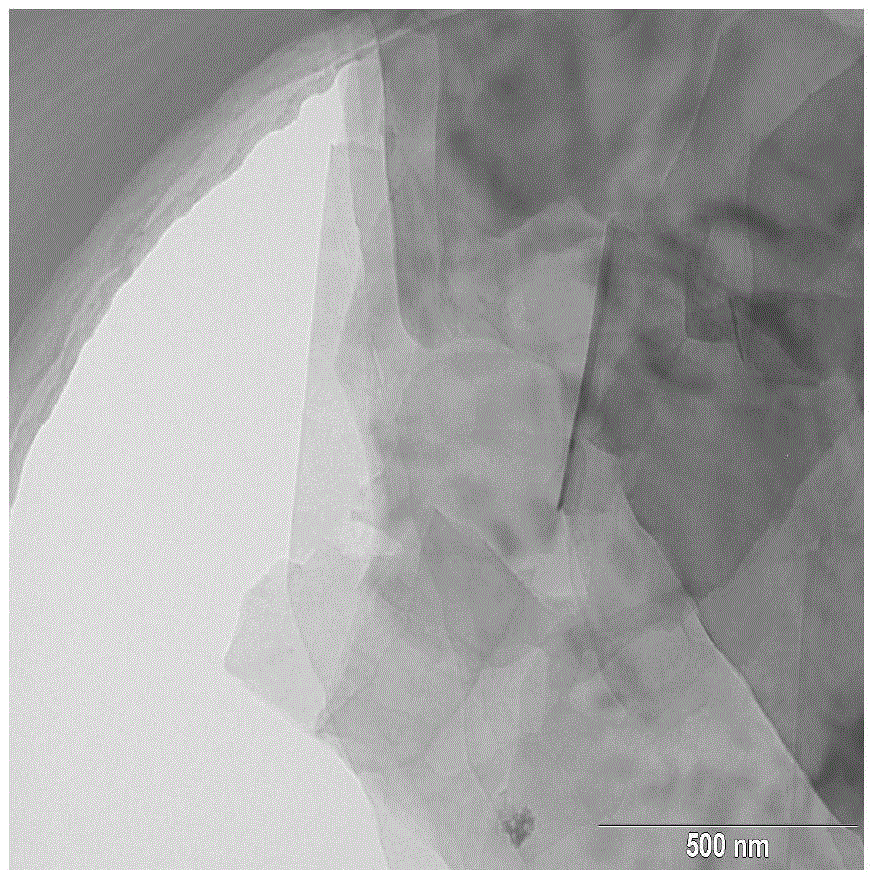

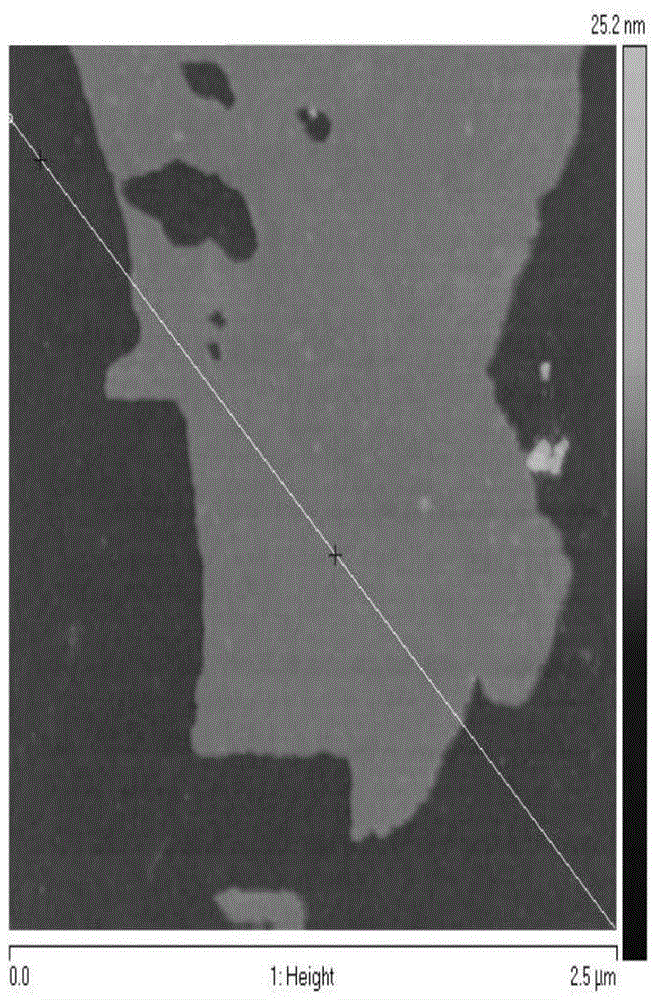

[0043] The SEM image of the boron nitride nanosheets prepared by the method of this embodiment is as follows Figure 4 shown by Figure 4 Compared Figure 1-Figure 3c It can be seen that after the high temperature heat treatment time is changed from 72 hours to 5 hours, the quality of the prepared product boron nitride nanosheets decreases.

Embodiment 3

[0045] This embodiment provides a method for preparing boron nitride nanosheets by exfoliating boron nitride powder with eutectic salt at high temperature. This method is basically the same as the method in Example 1, except that the high temperature of step (2) The time of heat treatment was changed from 72 hours to 12 hours, and the temperature of high temperature heat treatment was unchanged.

[0046] The SEM image of the boron nitride nanosheets prepared by the method of this embodiment is as follows Figure 5 shown by Figure 5 Compared Figure 1-Figure 3c It can be seen that after the high temperature heat treatment time is changed from 72 hours to 12 hours, the quality of the prepared product boron nitride nanosheets decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com