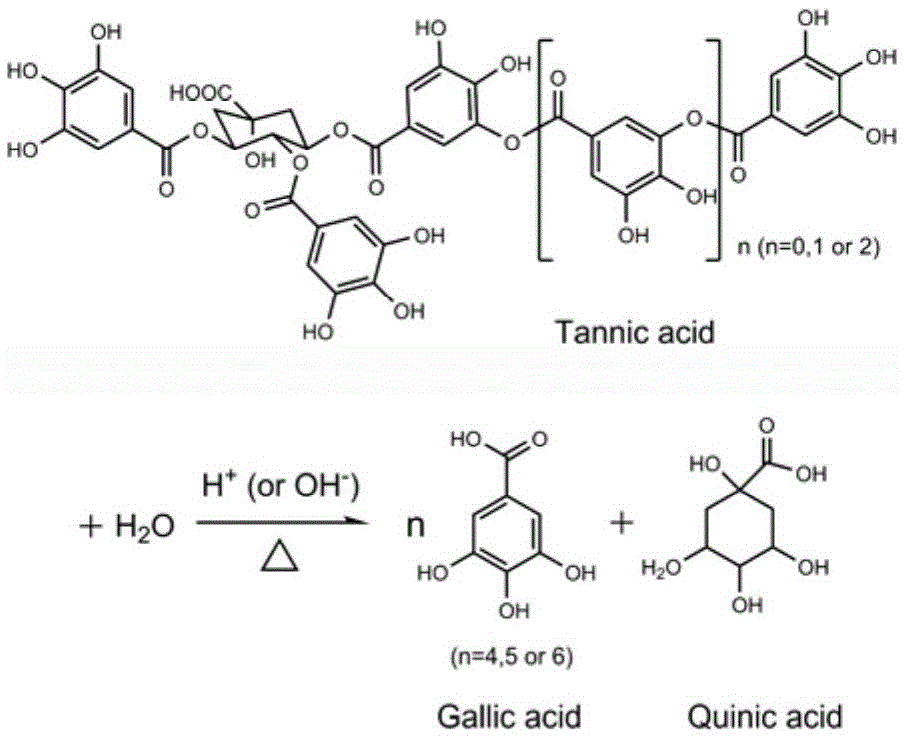

Method for microwave-ultrasonic-assistant hydrolysis extraction of Caesalpinia spiosa pod gallic acid

A gallic acid and microwave ultrasonic technology, applied in the preparation of carboxylic acid esters/lactones, organic chemistry, etc., can solve the problems of restricted enzymatic hydrolysis speed, difficult control, slow solvent diffusion, etc., and achieve high economic and practical value and high yield Improvement and ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] (1) Tara fruit pod powder is used as raw material 100g, add 1L of deionized water, condense and reflux for 2h, and filter to obtain the filtrate. Take 50ml of filtrate, add 0.25g of anti-oxidant reagent TBHQ, 6g of strongly basic 201*7 ion exchange resin catalyst (dry weight), and heat with the aid of microwave ultrasound at a power of 385W for 15min to extract gallic acid. Solid-liquid separation after cooling and crystallization of the hydrolyzate, solid phase dissolving with hot water, after activated carbon decolorization, recrystallization, vacuum drying, gallic acid product 2.06g is obtained, and the product is 98.3% (wt%) through HPLC analysis purity, and the yield is 41.9%, and the product yield is 1.3 times that without adding acidic ion exchange resin catalyst.

[0024] (2) Tara pod powder is used as raw material 100g, add 1L of deionized water, condense and reflux for 2h, and filter to obtain the filtrate. Take 50ml of filtrate, add 0.25g of antioxidant reag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com