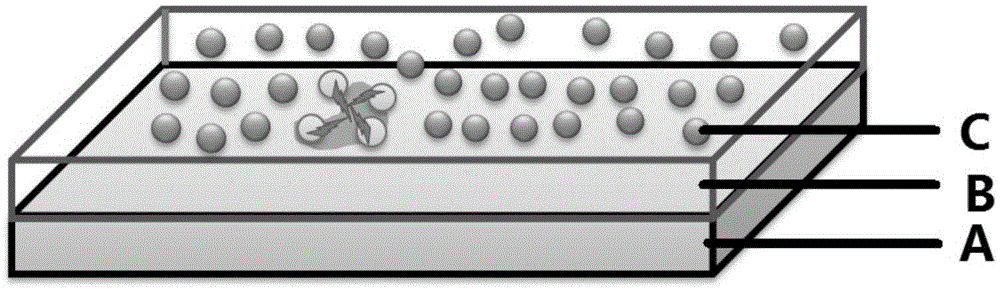

Superhydrophobic self-healing intelligent nano-coating and preparation method thereof

A nano-coating and self-healing technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems that corrosion inhibitors cannot be effectively encapsulated, cannot respond to changes in corrosive environment, and affect the sensitivity of metal corrosion, achieve good application prospects, prevent Corrosion, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of sol-gel self-assembled nanoparticle coating

[0037] Mix 26.9mL of 3-glycidyl ether propyltrimethoxysilane with 9.08mL of ethyl orthosilicate, then slowly add 12.8mL of 0.05M acetic acid aqueous solution dropwise thereto, stir for three hours and then let stand for two days.

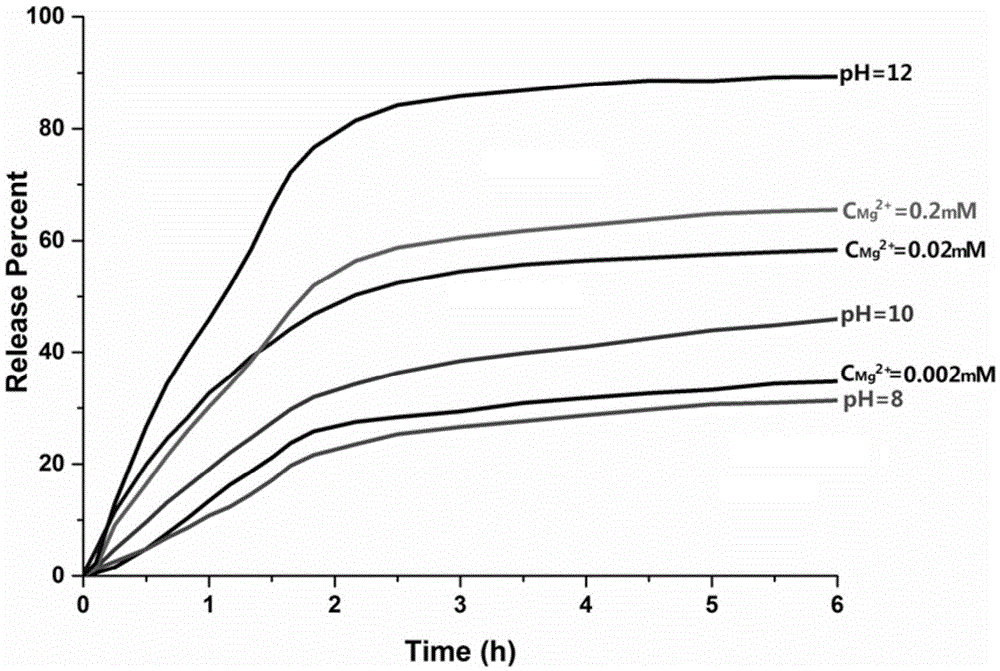

[0038] 2. Preparation of functionalized mesoporous nano-silica particles

[0039] Dissolve 0.4g NaOH solid in 5mL deionized water, and the concentration is 2mol L -1 Mix 3.5 mL of NaOH solution with 1 g of cetyltrimethylammonium bromide (CTAB) and 480 mL of deionized water, heat the reaction system to 80°C at a speed of 500 rpm, and keep it warm for 30 minutes for activation. Measure 5mL tetraethyl orthosilicate (TEOS) for injection and add it dropwise to the system, complete the addition in 30 minutes, and react at 80°C for 2 hours. After the reaction was completed, it was filtered while it was hot, the product was fully washed with heated deionized water, and vacuum-dried at ...

Embodiment 2

[0055] 1. Preparation of sol-gel self-assembled nanoparticle coating

[0056] 40.44 mL of zirconium n-propoxide was mixed with 13.7 mL of tetraethyl orthosilicate, and then 19.4 mL of 0.05 M acetic acid aqueous solution was slowly added dropwise thereto, stirred for four hours and then allowed to stand for sixty hours.

[0057] 2. Preparation of functionalized mesoporous nano-silica particles

[0058] Dissolve 0.4g NaOH solid in 5mL deionized water, and the concentration is 2mol L -1 Mix 3.5 mL of NaOH solution with 1 g of cetyltrimethylammonium bromide (CTAB) and 480 mL of deionized water, heat the reaction system to 80°C at a speed of 500 rpm, and keep it warm for 30 minutes for activation. Measure 5mL tetraethyl orthosilicate (TEOS) for injection and add it dropwise to the system, complete the addition in 30 minutes, and react at 80°C for 2 hours. After the reaction was completed, it was filtered while it was hot, the product was fully washed with heated deionized water, ...

Embodiment 3

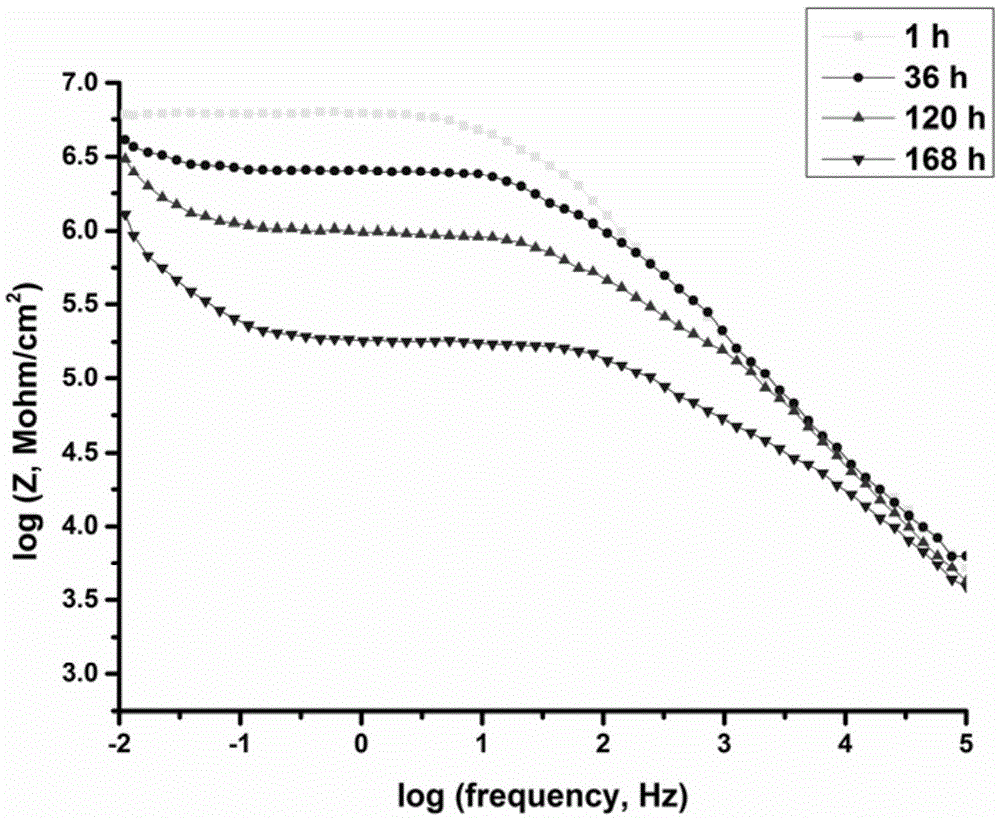

[0069] 1. Preparation of sol-gel self-assembled nanoparticle gels

[0070] Mix 40.44mL of 3-glycidyl ether propyl trimethoxysilane with 13.7mL of ethyl orthosilicate, then slowly add 19.4mL of 0.05M acetic acid aqueous solution dropwise therein, stir for five hours and then let stand for three days.

[0071] 2. Preparation of coatings without functionalized mesoporous nano-silica particles:

[0072] To 8 mL of the aged gel was added 1.14 mL of the crosslinker triethylenetetramine. Select AZ91D magnesium alloy, degrease with acetone, polish with 1500-grit sandpaper in turn, wash with ethanol and dry, hang and immerse in the above gel at a speed of 1.2cm / min, soak for 2min, and then pull it up at a speed of 1.2cm / min. Dry at 100°C for two hours. Label this coating sample as Coating No. 1.

[0073] 3. Preparation of coatings doped with functionalized mesoporous nano-silica particles

[0074] Dissolve 0.4g NaOH solid in 5mL deionized water, and the concentration is 2mol L -1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com