A novel soil stabilizer

A soil stabilizer and a new type of technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problem that the penetration depth of the soil stabilizer is not so ideal, and achieve high compressive strength, large penetration depth, and water resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this implementation, the length of polypropylene fiber is 7mm, and the modulus of sodium silicate is 2.2;

[0029] A new type of soil stabilizer, made of the following components in proportion by weight: 5 parts of ordinary Portland cement, 24 parts of polyurethane modified polyacrylate composite rubber powder, 6 parts of sodium alginate, and 6 parts of calcium sulfate , 10 parts of silica fume, 4 parts of polypropylene fiber, 3 parts of triisopropanolamine, 3 parts of lithium hydroxide, 1 part of aluminum chloride, 2 parts of sodium silicate, 2 parts of sodium methyl silicate, 4 parts of talcum powder , 3 parts of perlite, 2 parts of polycarboxylate superplasticizer, 5 parts of hydroxyethyl cellulose, and 0.02 part of modified rosin resin.

Embodiment 2

[0031] In this implementation, the length of polypropylene fiber is 5mm, and the modulus of sodium silicate is 2.0;

[0032] A new type of soil curing agent, which is made of the following components by weight: 4 parts of ordinary Portland cement, 20 parts of polyurethane modified polyacrylate composite rubber powder, 5 parts of sodium alginate, and 4 parts of calcium sulfate , 8 parts of silica fume, 3 parts of polypropylene fiber, 2 parts of triisopropanolamine, 2 parts of lithium hydroxide, 1 part of aluminum chloride, 1 part of sodium silicate, 1 part of sodium methyl silicate, 3 parts of talcum powder , 3 parts of perlite, 1 part of polycarboxylate superplasticizer, 3 parts of hydroxyethyl cellulose, and 0.01 part of modified rosin resin.

Embodiment 3

[0034] In this implementation, the length of polypropylene fiber is 8mm, and the modulus of sodium silicate is 2.4;

[0035] A new type of soil curing agent, which is made of the following components by weight: 6 parts of ordinary portland cement, 28 parts of polyurethane modified polyacrylate composite rubber powder, 7 parts of sodium alginate, and 8 parts of calcium sulfate , 12 parts of silica fume, 5 parts of polypropylene fiber, 4 parts of triisopropanolamine, 4 parts of lithium hydroxide, 2 parts of aluminum chloride, 2 parts of sodium silicate, 2 parts of sodium methyl silicate, 4 parts of talcum powder , 4 parts of perlite, 3 parts of polycarboxylate superplasticizer, 7 parts of hydroxyethyl cellulose, and 0.03 part of modified rosin resin.

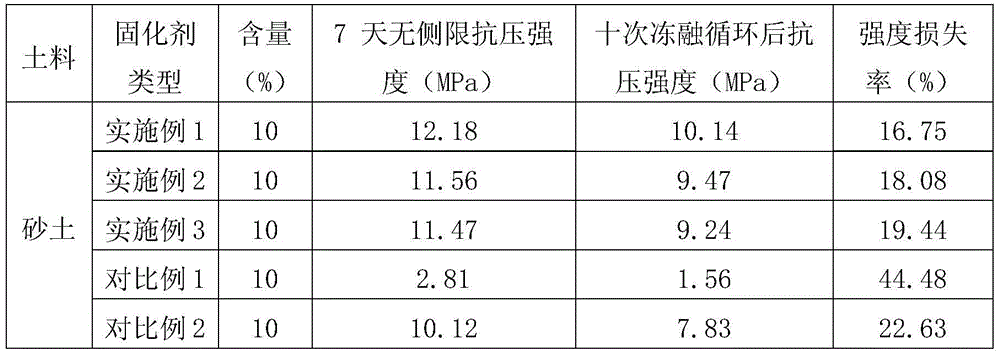

[0036] In addition, in order to illustrate the effect of the soil solidifying agent of the present invention, the applicant has carried out following performance test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com