Strontium manganate nanowires and microwires and preparation method thereof

A strontium manganate and nanowire technology, which is applied in the field of nano and micron wire preparation, can solve the problems of easy sintering of samples, high-temperature calcination, and difficulty in realization, and achieve low cost, low reaction temperature, and overcoming difficult doping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

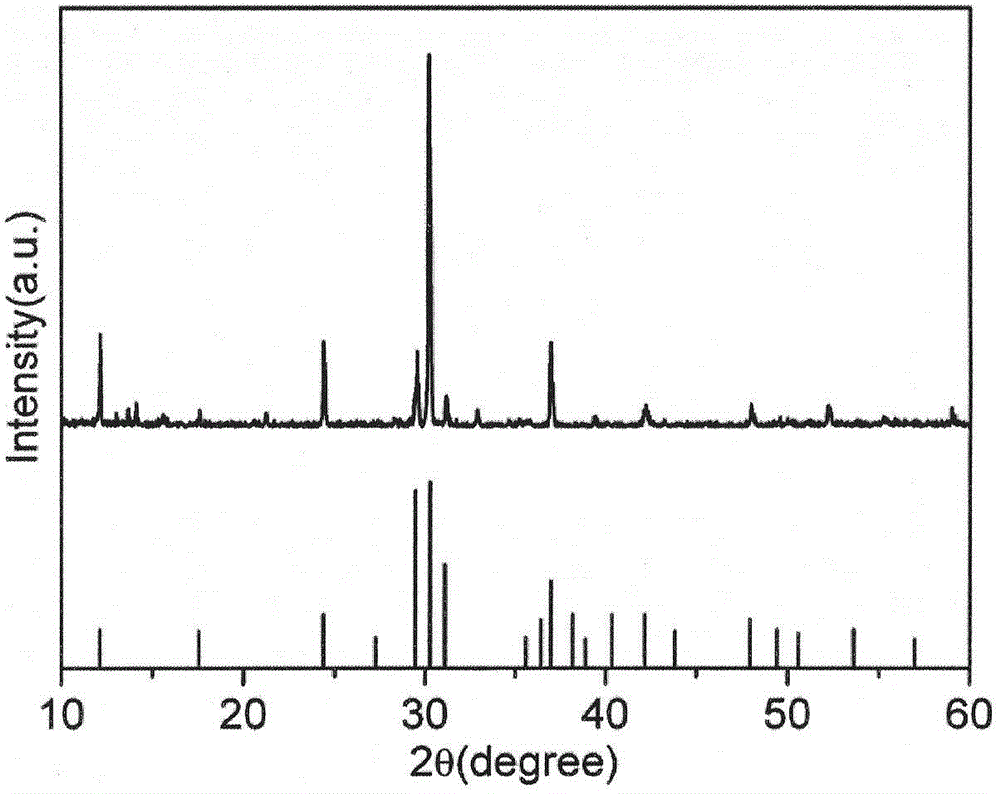

[0022] Dissolve strontium salt, manganese salt and lanthanum salt in water at a ratio of 0.3:3:0.7, and stir at room temperature until completely dissolved to form an aqueous solution. Add 24g of mineralizer to the above aqueous solution, and stir evenly at room temperature. The obtained precursor solution was put into a high-temperature hydrothermal kettle, and put into a blast drying oven for reaction, the reaction temperature was 275° C., and the reaction time was 28 hours. After the reaction was completed, it was cooled with the furnace, and the reaction product was taken out, washed with ethanol and deionized water, dried at 100°C, and samples were collected. The prepared sample is observed and tested using a scanning electron microscope and an X-ray diffractometer, according to X-ray diffraction (XRD) ( figure 1 ), where the ordinate is the relative intensity, and the abscissa is the diffraction angle. From the position and relative intensity of each diffraction peak, i...

Embodiment 2

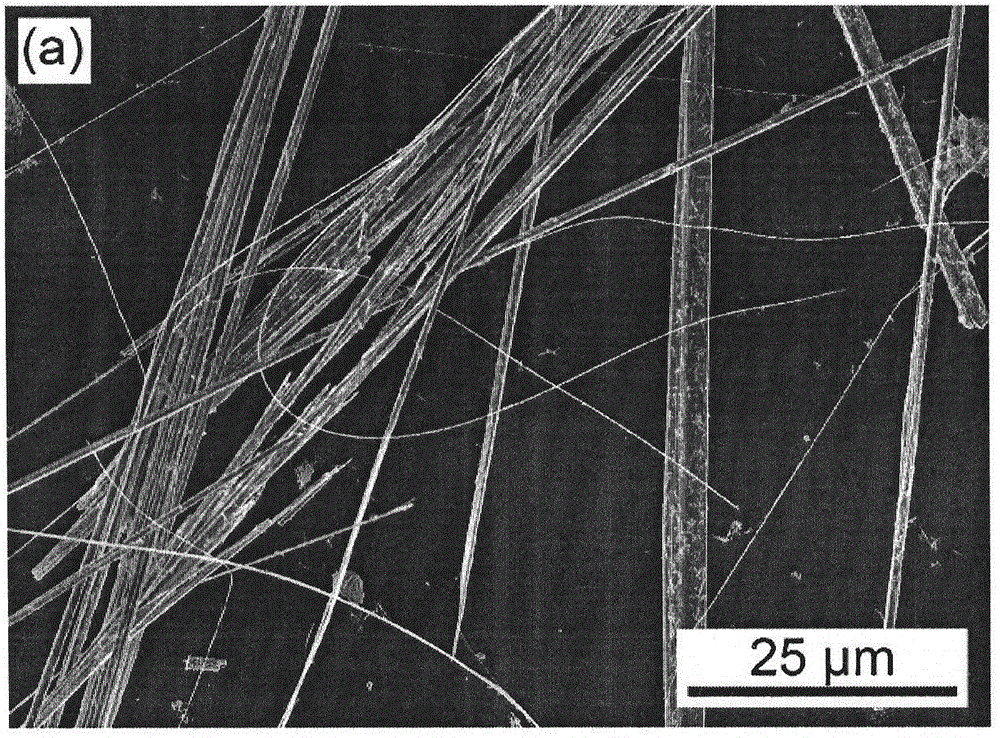

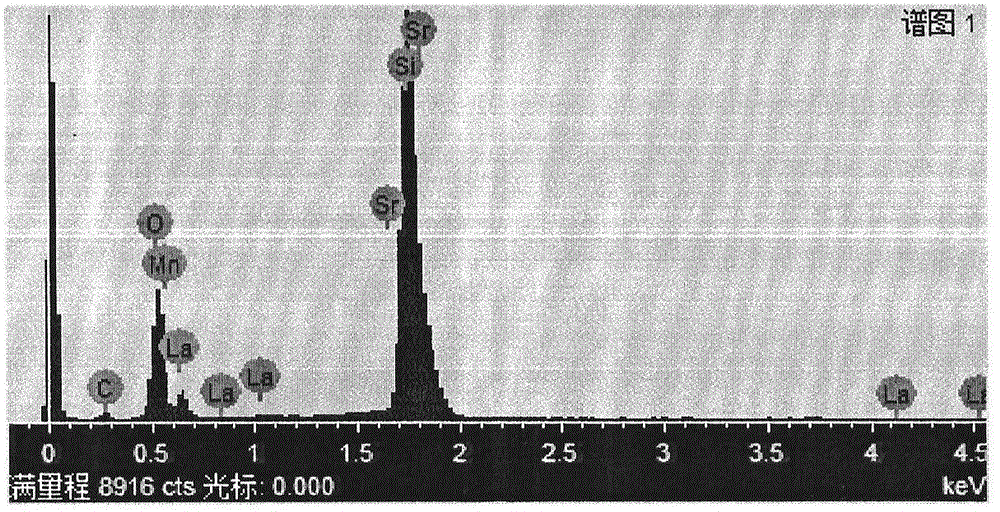

[0024] Dissolve strontium salt and manganese salt in water at a ratio of 1:3, and stir at room temperature until completely dissolved to form an aqueous solution. Add 24g of mineralizer to the above aqueous solution, and stir evenly at room temperature. The precursor solution was put into a high-temperature hydrothermal kettle, and put into a blast drying oven for reaction, the reaction temperature was 275° C., and the reaction time was 30 hours. After the reaction was completed, it was cooled with the furnace, and the reaction product was taken out, washed with ethanol and deionized water, dried at 100°C, and samples were collected. The obtained samples were observed and tested using a scanning electron microscope and an X-ray diffractometer, from the obtained scanning electron microscope (SEM) photos ( Figure 4 ) and energy spectrum analysis ( Figure 5 ) shows that strontium manganate ultra-long nanowires and micron wires have been successfully prepared, with diameters o...

Embodiment 3

[0026] Dissolve strontium salt, manganese salt and lanthanum salt in water at a ratio of 0.3:3:0.7, and stir at room temperature until completely dissolved to form an aqueous solution. Add 24g of mineralizer to the above aqueous solution, and stir evenly at room temperature. The obtained precursor solution was put into a high-temperature hydrothermal kettle, and put into a blast drying oven for reaction, the reaction temperature was 275° C., and the reaction time was 28 hours. After the reaction was completed, it was cooled with the furnace, and the reaction product was taken out, washed with ethanol and deionized water, dried at 100°C, and samples were collected. The prepared sample is observed and tested using a scanning electron microscope and an X-ray diffractometer, according to X-ray diffraction (XRD) ( figure 1 ), where the ordinate is the relative intensity, and the abscissa is the diffraction angle. From the position and relative intensity of each diffraction peak, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com