Coal chemical strong brine zero emission and salt screening technology

A technology of concentrated brine and zero discharge, which is applied in oxidized water/sewage treatment, alkali metal sulfite/sulfate purification, multi-stage water treatment, etc. It can solve the problem of difficult to ensure zero discharge of concentrated brine and unsatisfactory wastewater treatment effect , Economical electricity price impact and other issues, to achieve the effect of reducing the scale of treatment and operating costs, high degree of automation, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

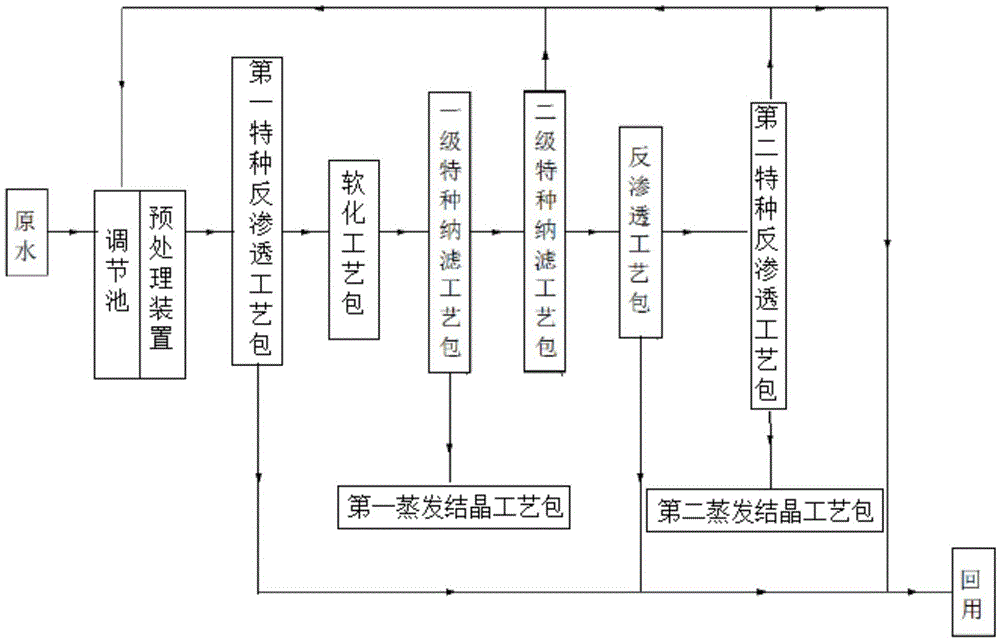

[0024] In the embodiment of the present invention, the zero discharge and salt separation process flow chart of the concentrated brine in the coal chemical industry is as follows figure 1 , the concentrated brine enters the first special reverse osmosis process package after passing through the regulating tank and pretreatment device, and its fresh water is reused. The first-level special nanofiltration process package separates the monovalent salt from the divalent salt. The product water on the concentrated water side of the first-level special nanofiltration process package is processed by the first evaporation crystallization process package to obtain industrial-grade sodium sulfate. The first evaporation crystallization process package The discharged mother liquor enters the second evaporation and crystallization process package, and the product water from the fresh water side of the first-level special nanofiltration process package enters the second-level special nanofil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com