A strain of Oleococcus graesiella sp.WBG-1 and its isolation and screening method and application

A technology of oleaginous algae and coccus, applied in the direction of microorganism-based methods, biochemical equipment and methods, single-cell algae, etc., can solve the problems of high energy consumption, easy pollution, genetic regulation, and lack of deep understanding of physiological regulation etc. to achieve high separation efficiency and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

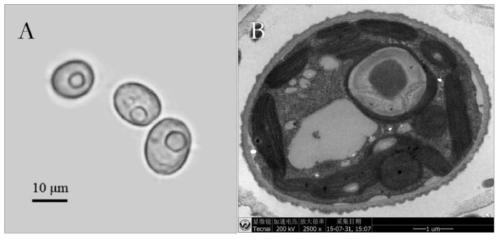

[0042] Embodiment 1: the separation and screening method of Oleococcus Graesiella sp.WBG-1, its steps are:

[0043] A method for separation and screening of Oleococcus Graesiella sp.WBG-1, the steps of which are:

[0044] 1. Water sample collection: A plankton collector made of 400-mesh gauze tulle draws the word "∞" below the water surface to enrich algae cells. The collected samples are placed in sterile bottles, and a small amount of concentrated BG-11 is added for cultivation. Base, and then stand for 3 days under low light, and then carry out the separation of algal species. The water samples in this example were collected from Yongsheng County, Yunnan Province.

[0045] 2. Separation and purification:

[0046] (1) Search and separation of target algae cells: Find the algae cells to be separated (target algae cells) under a 10X or 20X microscope, then bring the micropipette (0.1mm inner diameter) close to the target cells and quickly lift it up, using The siphon action...

Embodiment 2

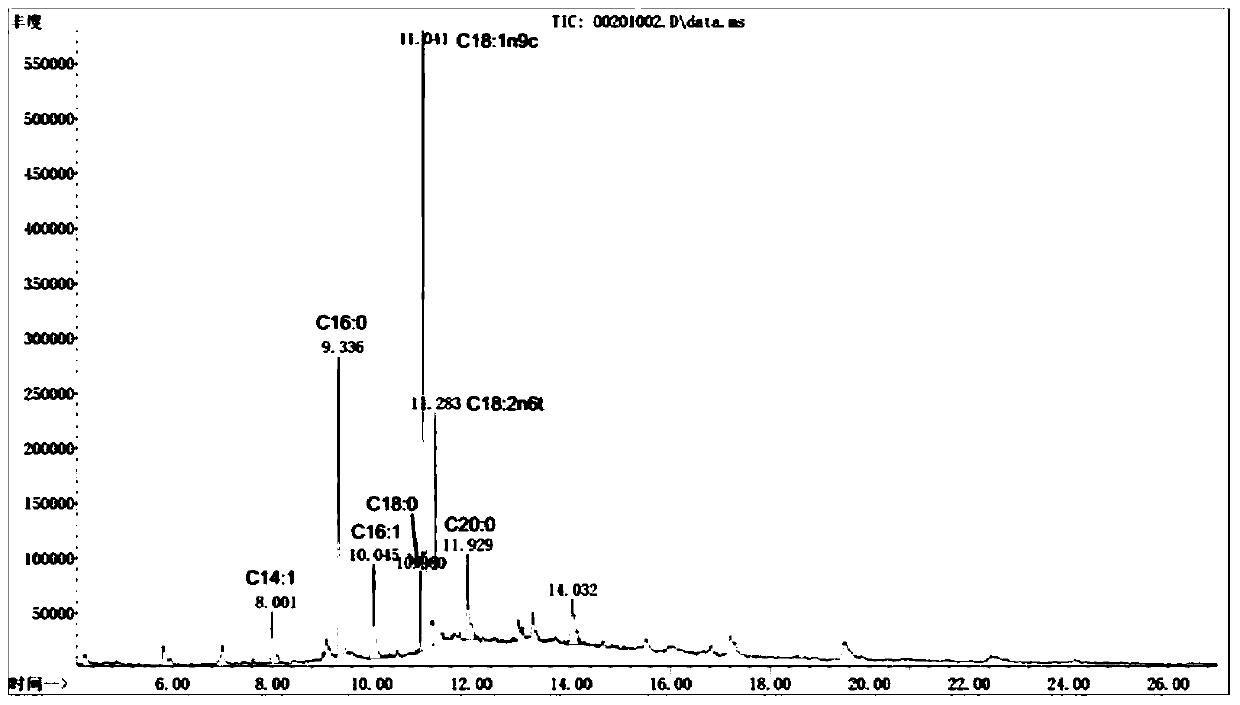

[0060] Example 2: Expanded cultivation of Oleococcus Graesiella sp.WBG-1 and its use in the production of microalgae oil (biodiesel feedstock).

[0061] A kind of application of oleococcus Graesiella sp.WBG-1 in microalgae biodiesel raw material, its steps are:

[0062] 1. Reactor preparation: first wipe the inner surface of the incubator with 75% ethanol three times, then inject 40 liters of culture water that has been boiled and sterilized and cooled to room temperature, and put the boiled and sterilized vent tube and sand core gas diffuser into the incubator In the process, turn on the gas source and start ventilating (air flow rate 3L / min), and the gas to be ventilated is air / carbon dioxide mixed gas (CO 2 / air=1 / 99, V / V) and sterilized by filtration through a 0.22 μm pore size filter.

[0063] 2. Medium preparation: According to the improved BG11 medium formula 1, add the medium components one by one, stir thoroughly after each component is added, and then add the next c...

Embodiment 3

[0069] Example 3: Expanded culture of Oleococcus Graesiella sp.WBG-1 and its use in the production of microalgae protein.

[0070] A kind of application of Oleococcus Graesiella sp.WBG-1 in microalgae protein production, its steps are:

[0071] 1. Reactor preparation: first wipe the inner surface of the incubator with 75% ethanol three times, then inject 40 liters of culture water that has been boiled and sterilized and cooled to room temperature, and put the boiled and sterilized vent tube and sand core gas diffuser into the incubator In the process, turn on the gas source and start to ventilate (air flow rate 3L / min), and the gas to be ventilated is air / carbon dioxide mixture (CO 2 / air=1 / 99, V / V) and sterilized by filtration through a 0.22 μm pore size filter.

[0072] 2. Medium preparation: According to the improved BG11 medium formula 2, add the medium components one by one, stir thoroughly after each component is added, and then add the next component to prevent precipi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com