Preparation method and application of functional AOPAN-RC composite nanofiber film

A composite nanofiber and functional technology, applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of single functional effect modification, limited application fields, and low mechanical strength, so as to improve hydrophilicity and expand Application fields, effects of enhancing acid and alkali resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

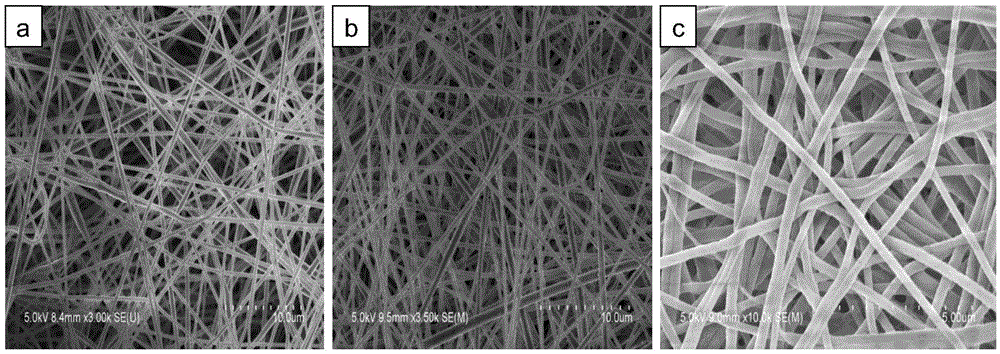

[0031] 1. First, accurately weigh 1.32g of cellulose acetate slices and 3.08g of PAN powder into a 50ml Erlenmeyer flask, then add 35.6g of DMF solvent, put it in a constant temperature water bath at 40°C, and stir it magnetically for 6 hours until fully dissolved. A PAN / CA composite spinning solution with a total mass fraction of 11% (wherein the mass ratio of PAN and CA is 7:3) was prepared.

[0032] 2. Put the PAN / CA homogeneous spinning solution prepared in step 1 into a 10ml syringe, and use a grinder to grind the syringe needle with an inner diameter of 0.7mm to make it smooth. The positive pole of the high-voltage power supply is connected to the needle point of the syringe fixed horizontally on the syringe pump. At room temperature, the flow rate of the spinning solution was adjusted to 0.5ml / h, the applied voltage was 18kv, and the distance between the needle tip and the collector was 20cm. A piece of aluminum foil was covered on a grounded fixed rectangular copper m...

Embodiment 2

[0037] 1. First, accurately weigh 1.20g of cellulose acetate slices and 2.80g of PAN powder into a 50ml Erlenmeyer flask, then add 36.0g of DMF solvent, put it in a constant temperature water bath at 40°C, and stir it magnetically for 6 hours until fully dissolved. A PAN / CA composite spinning solution with a total mass fraction of 10% (wherein the mass ratio of PAN and CA is 7:3) was prepared.

[0038] 2. Put the PAN / CA homogeneous spinning solution prepared in step 1 into a 10ml syringe, and use a grinder to grind the syringe needle with an inner diameter of 0.7mm to make it smooth. The positive pole of the high-voltage power supply is connected to the needle point of the syringe fixed horizontally on the syringe pump. At room temperature, the flow rate of the spinning solution was adjusted to 0.8ml / h, the applied voltage was 19kv, and the distance between the needle tip and the collector was 20cm. A piece of aluminum foil was covered on a grounded fixed rectangular copper m...

Embodiment 3

[0043] 1. First, accurately weigh 1.44g of cellulose acetate slices and 3.36g of PAN powder into a 50ml Erlenmeyer flask, then add 35.2g of DMF solvent, put it in a constant temperature water bath at 40°C, and stir it magnetically for 6 hours until fully dissolved. A PAN / CA composite spinning solution with a total mass fraction of 12% (wherein the mass ratio of PAN and CA is 7:3) was prepared.

[0044] 2. Put the PAN / CA homogeneous spinning solution prepared in step 1 into a 10ml syringe, and use a grinder to grind the syringe needle with an inner diameter of 0.7mm to make it smooth. The positive pole of the high-voltage power supply is connected to the needle point of the syringe fixed horizontally on the syringe pump. At room temperature, the flow rate of the spinning solution was adjusted to 0.7ml / h, the applied voltage was 18.5kv, and the distance between the needle tip and the collector was 19cm. A piece of aluminum foil was covered on a grounded fixed rectangular copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com