On-line detection device and detection method for denitrification rate of activated sludge

A technology of activated sludge and detection devices, which is applied in the direction of measuring devices, color/spectral characteristic measurement, and material analysis through optical means, and can solve the problems of controlling processes, operating methods and strategies, and real-time detection and dynamics during process operation. Adjustment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1, activated sludge denitrification rate online detection device

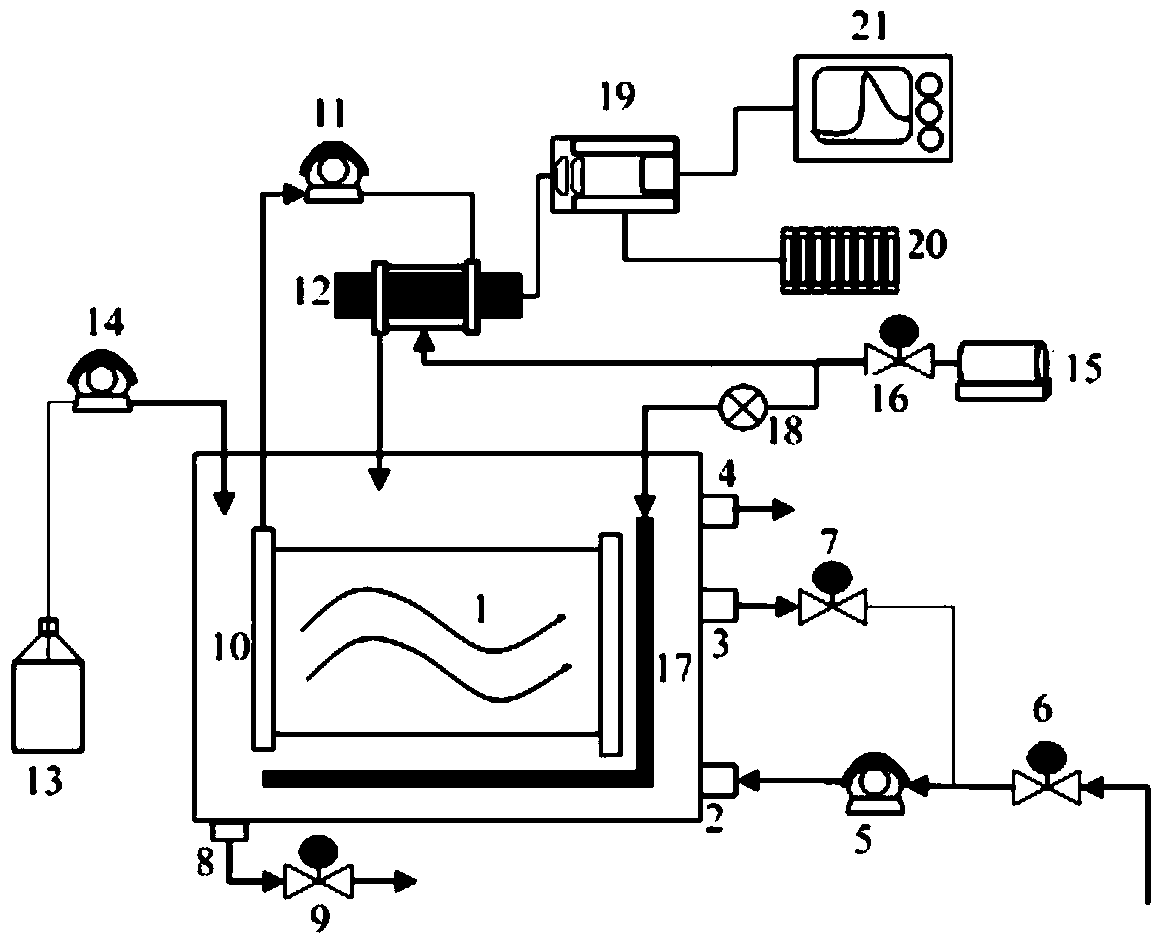

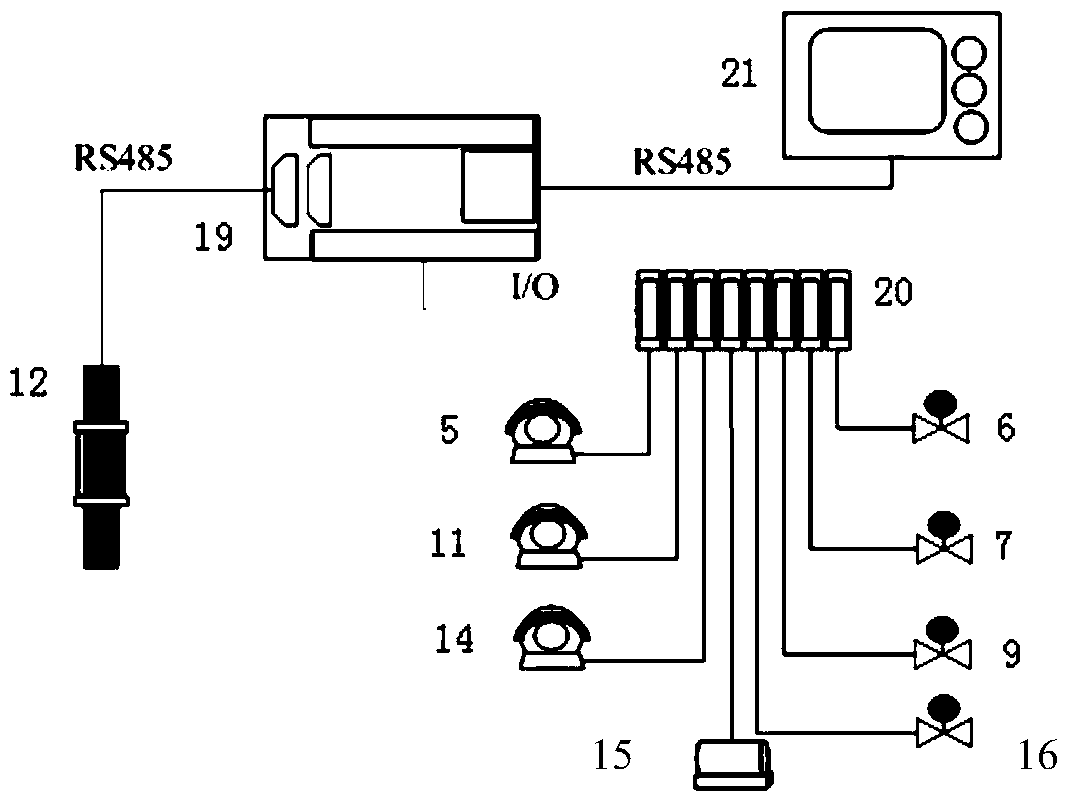

[0082] Such as figure 1 As shown, the activated sludge denitrification rate online detection device of the present invention includes a reaction system, a carbon source dosing system, a nitrate nitrogen detection system, a cleaning system, a process control system and a data acquisition and processing system;

[0083] The reaction system includes a bioreactor 1, which is an engineering plastic cuboid container of 450×4500×150mm (LHW), with an effective volume of 20L. The side wall of the bioreactor 1 is sequentially provided with a reaction tank water inlet 2, a reaction tank circulation port 3 and a reaction tank overflow port 4 from bottom to top. The water inlet 2 of the reaction tank is connected to the water inlet solenoid valve 6 through the pipeline (hole / pipe inner diameter 25 mm) provided with the water inlet peristaltic pump 5; the circulation port 3 of the reaction tank is connecte...

Embodiment 2

[0090] Embodiment 2, using the activated sludge denitrification rate online detection device in embodiment 1 to carry out on-line detection of the denitrification rate in the activated sludge in the sewage denitrification process

[0091] A sewage treatment plant adopts the AAO process, with a treatment capacity of 20,000 tons per day. The designed hydraulic retention time is 1.5 hours in the anaerobic section, 3.5 hours in the anoxic section, and 10 hours in the aerobic section. The sludge reflux ratio is 100%, and the mixed liquor reflux ratio is 200%.

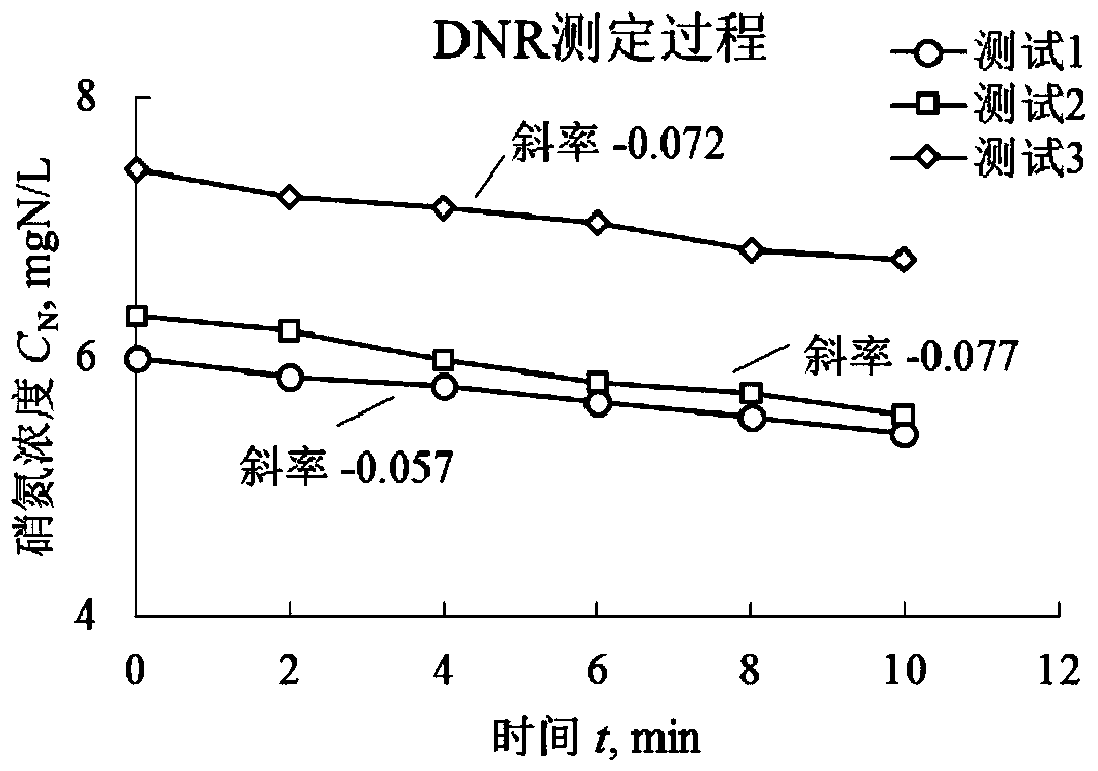

[0092] The sewage denitrification process generally includes a pre-anoxic pool and a post-aerobic pool. When the device of the present invention is in use, it is placed at the front end of the anoxic pool, and the sludge in the anoxic pool is collected to measure the denitrification rate. , to transmit the denitrification activity evaluation data to the central control room for the reference of process personnel, the specifi...

Embodiment 3

[0112] Example 3. Using the activated sludge denitrification rate online detection device in Example 1 to conduct online control of the carbon source dosage in the sewage denitrification process

[0113] Such as Figure 4 The process optimization flow chart based on the denitrification rate is shown, and the device in Example 1 can also be used to collect concentration data from the effluent water quality meter, and estimate the removal of nitrate in the anoxic section through process analysis, so as to calculate the carbon source that needs to be added Quantity, control the frequency converter, change the working frequency of the carbon source dosing pump, and add carbon source from the carbon source storage tank to the anoxic pool. The specific operations are as follows:

[0114] (A) Water intake stage: start the sampling peristaltic pump (the rated flow rate is 5L / min, and the effective volume of the bioreactor is 20L), open the sampling solenoid valve, close the circulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com