Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of long electron transmission path, reduced photoelectric performance, current loss, etc., to improve photoelectric performance, reduce interface recombination, and improve optical properties effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of perovskite solar cell of the present invention comprises the following steps:

[0030] (1) Etching of transparent conductive electrodes: the conductive substrate is etched and corroded by plasma to form a surface morphology with a certain roughness;

[0031] (2) Preparation of electron transport layer: cleaning the above-mentioned conductive substrate, and then preparing a seed layer by sputtering, hydrothermal method or electron beam deposition method;

[0032] The steps of preparing the seed layer by sputtering are as follows: place the processed conductive substrate into a vacuum device, and draw a vacuum to at least 8×10-4 Pa, through Ar and O 2 , the oxygen-argon flow ratio is 0.01-0.1, the working pressure is 0.5Pa, the DC magnetron sputtering current is 0.2-0.35A, and the voltage is 370-410V to obtain a dense seed layer with a thickness of 80-120nm. The dense seed layer is TiO 2 , ZnO or Al 2 o 3 electron transport layer;

[0033] T...

Embodiment 1

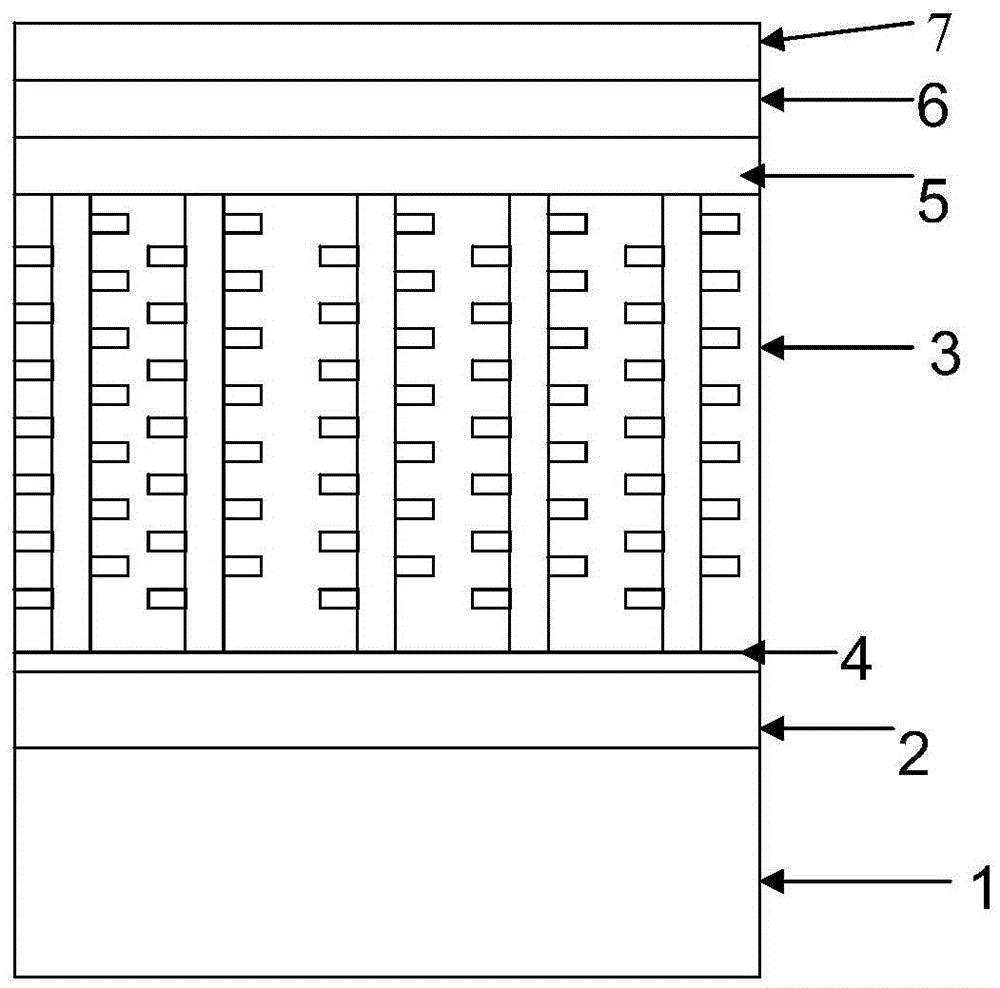

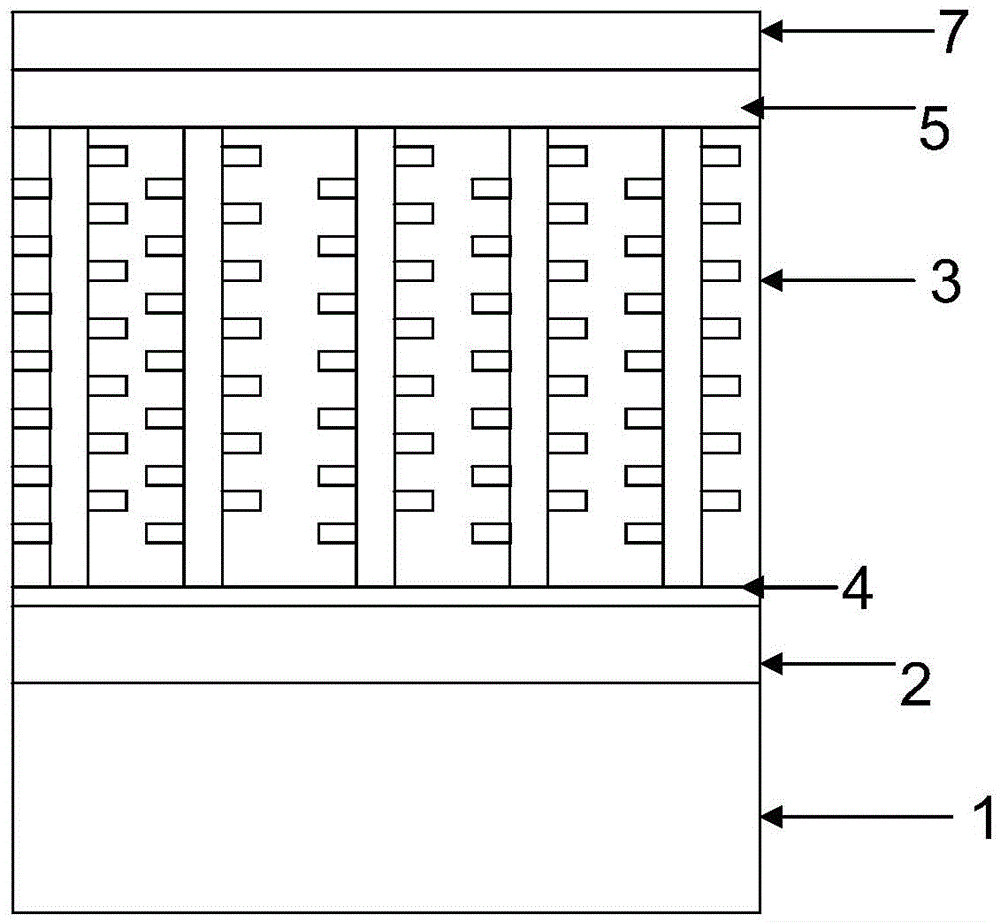

[0046] 1. Selection and treatment of substrate and upper electrode

[0047] Such as figure 1 and 2 As shown, the substrate 1 can choose flexible substrate materials such as glass, polyimide (PI), PET or PEN, and the conductive layer 2 can choose FTO (SnO 2 : F), ITO (In 2 o 3 : SnO 2 ) or IZO (In 2 o 3 : ZnO) or AZO (Al 2 o 3 : ZnO) or a mixture of several conductive materials; the conductive layer can be prepared by DC magnetron sputtering or radio frequency magnetron sputtering. Using In 2 o 3 4N purity IZO target prepared by doping 2% ZnO. Prepared by double-target DC magnetron sputtering method, the flow ratio of oxygen and argon is 0.01-0.1, the sputtering current is 0.1A-0.45A, the sputtering voltage is 300-600V, and the prepared sheet resistance is 5-10Ω / □, transparent A transparent conductive electrode with a pass rate of more than 80%. In addition, in order to increase the utilization rate of sunlight and prepare a high-quality electron transport layer 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com