Method for solid phase reaction one-step preparation of reduced graphene oxide/palladium composite nanometer electrocatalyst

A solid-phase reaction, electrocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve simple and controllable preparation methods, broad application prospects, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing reduced graphene oxide / palladium composite nano-electrocatalyst in one step by solid phase reaction, the technical scheme is as follows:

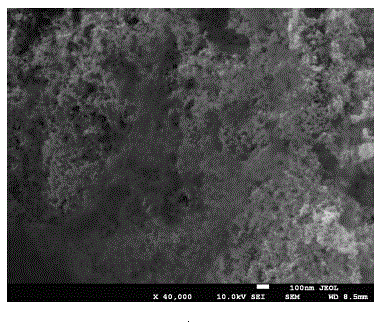

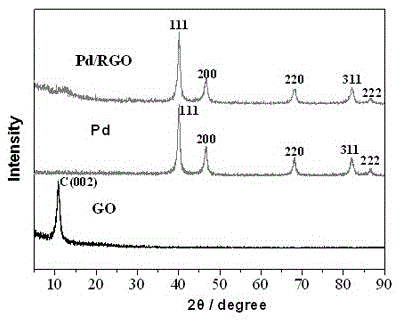

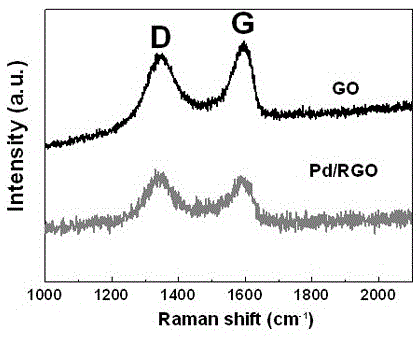

[0021] Weigh 0.448g (2mmol) of palladium acetate, 1.056g (6mmol) of ascorbic acid, and 0.015g (1% of the total mass fraction) of graphene oxide powder, mix palladium acetate and graphene oxide fully, add ascorbic acid, and test Mix and grind in a bowl for 1 hour, wash and dry to obtain the reduced graphene oxide / palladium composite nano-electrocatalyst, and its structure and appearance are as follows: figure 1 , figure 2 and image 3 As shown, the electrocatalytic performance of the catalyst for methanol and ethanol is as follows Figure 4 , Figure 5 shown. As a comparison, 0.448 g (2 mmol) of palladium acetate and 1.056 g (6 mmol) of ascorbic acid were weighed, mixed and ground in a mortar at room temperature for 1 hour, washed and dried to obtain a palladium nano-electrocatalyst.

Embodiment 2

[0023] A method for preparing reduced graphene oxide / palladium composite nano-electrocatalyst in one step by solid phase reaction, the technical scheme is as follows:

[0024] Weigh 0.46g (2mmol) of palladium nitrate, 0.704g (4mmol) of ascorbic acid, and 0.061g (5% of the total mass fraction) of graphene oxide powder, mix the palladium nitrate and graphene oxide fully, then add ascorbic acid, and test at room temperature mixing and grinding in a bowl for 20 minutes, washing and drying to obtain the reduced graphene oxide / palladium composite nano-electrocatalyst.

Embodiment 3

[0026] A method for preparing reduced graphene oxide / palladium composite nano-electrocatalyst in one step by solid phase reaction, the technical scheme is as follows:

[0027] Weigh 0.46g (2mmol) of palladium nitrate, 0.303g (8mmol) of sodium borohydride, and 0.085g (10% of the total mass fraction) of graphene oxide powder, mix palladium nitrate and graphene oxide fully, and then add sodium borohydride, Mix and grind in a mortar for 40 minutes at normal temperature, wash and dry to obtain the reduced graphene oxide / palladium composite nanometer electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com