Sulfur-containing Fe-based catalyst as well as preparation method and application thereof

An iron-based catalyst, content technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low selectivity of low-carbon olefins and low conversion rate of CO and other problems, to achieve the effect of improving the selectivity of low-carbon olefins, increasing the conversion rate, and improving the activity of water vapor conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

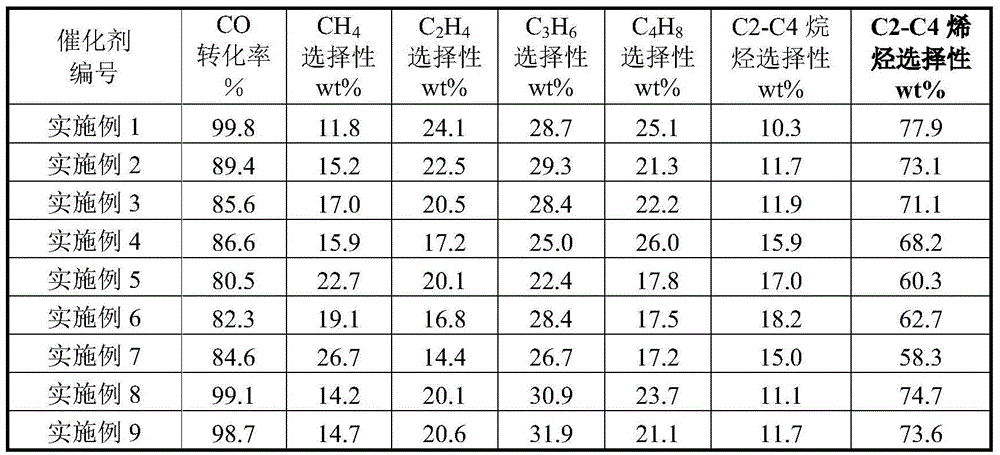

Embodiment 1

[0029] Weigh 100.0 grams of α-alumina (α-Al 2 o 3 ) powder in a ball mill for 1 hour to make a mill mix G for use; add deionized water to the above mill mix G for kneading and extrusion molding; after drying, roast at a temperature of 700°C After cooling for 3 hours, it was crushed and sieved into 40-60 meshes to prepare α-alumina carrier H; 78.5 grams of ferric nitrate nonahydrate, 25.2 grams of 50% manganese nitrate solution, 29.3 grams of anhydrous calcium nitrate, and 5.0 grams of nitric acid hexahydrate Gadolinium is dissolved in 20.0 grams of deionized water to make a mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated on 63.0 grams of prepared α-alumina H to obtain a catalyst precursor J; the impregnated The catalyst precursor J was dried at 110°C, and then calcined at a temperature of 600°C for 2 hours to obtain an iron-based catalyst K; the iron-based catalyst K was impregnated in ammonium bisulfate solution to obtain...

Embodiment 2

[0031] Weigh 100.0 grams of α-alumina (α-Al 2 o 3 ) powder in a ball mill for 1 hour to make a mill mix G for use; add deionized water to the above mill mix G for kneading and extrusion molding; bake at a temperature of 600°C after drying After cooling for 6 hours, crush and sieve into 40-60 meshes to prepare α-alumina carrier H; 52.3 grams of ferric nitrate nonahydrate, 12.6 grams of 50% manganese nitrate solution, 11.7 grams of anhydrous calcium nitrate, and 2.5 grams of nitric acid hexahydrate Gadolinium is dissolved in 20.0 grams of deionized water to make a mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated in 80.0 grams of prepared α-alumina H to obtain a catalyst precursor J; the impregnated The catalyst precursor J was dried at 110°C and then calcined at a temperature of 700°C for 1 h to obtain the iron-based catalyst K; the iron-based catalyst K was impregnated in ammonium bisulfate solution to obtain a sulfur-contai...

Embodiment 3

[0033] Weigh 100.0 grams of α-alumina (α-Al 2 o 3 ) powder in a ball mill for 1 hour to make a mill-mix G for use; add deionized water to the above-mentioned mill-mix G for kneading and extrusion; after drying, roast at a temperature of 900°C After cooling for 1 hour, crush and sieve into 40-60 meshes to prepare α-alumina carrier H; 52.3 grams of ferric nitrate nonahydrate, 12.6 grams of 50% manganese nitrate solution, 14.6 grams of anhydrous calcium nitrate, and 24.9 grams of nitric acid hexahydrate Gadolinium is dissolved in 20.0 grams of deionized water to make a mixed solution I; under the condition of a vacuum of 80kPa, the above mixed solution I is impregnated on 70.0 grams of prepared α-alumina H to obtain a catalyst precursor J; the impregnated The catalyst precursor J was dried at 110°C and then calcined at a temperature of 450°C for 6 hours to obtain an iron-based catalyst K; the iron-based catalyst K was impregnated in ammonium bisulfate solution to obtain a sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com