Reaction device and technology for preparing chlorosulfonated chloroethylene through gas-solid phase method

A chlorosulfonated vinyl chloride and reaction device technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of uneven material irradiation, difficult control, uneven reaction, etc., to improve the utilization rate of raw materials, ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

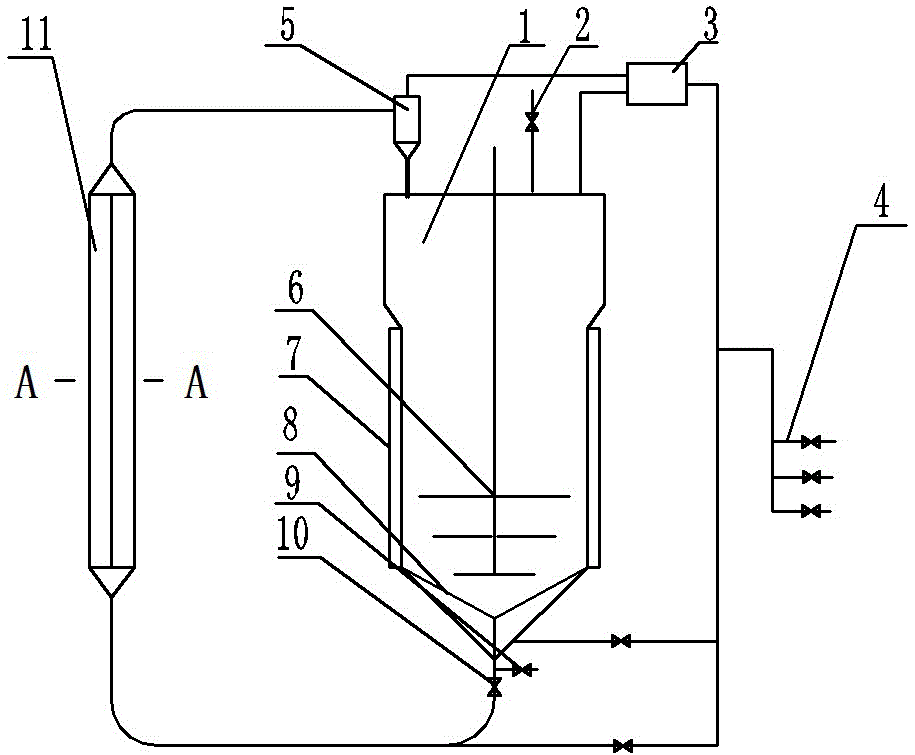

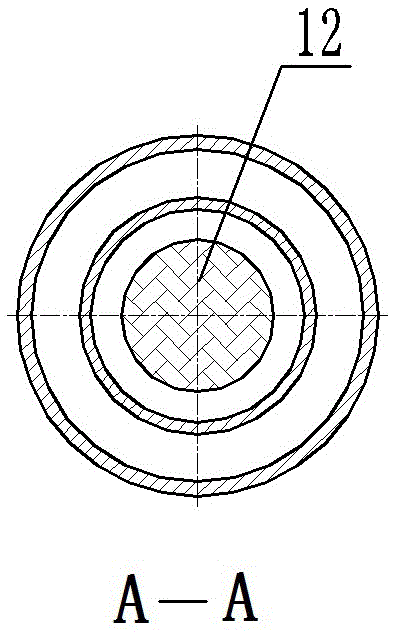

[0026] See attached figure 1 And figure 2 , This device adopts fluidized bed reactor and riser reactor to operate, and realizes the decoupling of the two processes of initiation and reaction. The specific operation process is as follows. The raw materials are fed into the fluidized bed reactor 1 through the feed valve 2 , Chlorine, sulfur dioxide and nitrogen are fed into the inlet pipe 4 in a certain proportion. The mixed gas enters the fluidized bed reactor from the inlet at the bottom of the fluidized reactor 1 through the gas distribution plate 8. The raw materials are in the gas flow and stirring 6 Under the action, the uniform mixing and fluidization of the gas-solid phase are realized, the temperature in the fluidized bed reactor 1 is controlled at 30-100°C, the pressure of the reactor is controlled at 0.05-0.15MPa, and the bottom of the fluidized bed reactor 1 is opened. Valve 10, the gas-solid phase mixture enters the riser reactor 11 under the blowing of the mixed ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com