Efficient and environment-friendly film-stripping solution capable of keeping copper surface bright and concentrated solution of film-stripping solution

A technology of concentrated liquid and copper surface, which is applied in the field of film stripping liquid and its concentrate, can solve the problems of difficult to achieve high film stripping at the same time, reduce the reoxygenation capacity of natural water bodies, and destroy water ecosystems, so as to improve the quality of film stripping, Improve the fading rate and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

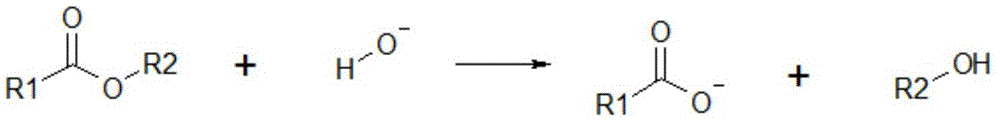

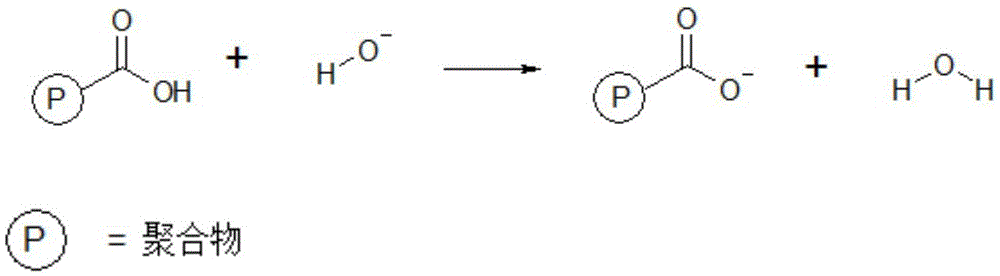

Method used

Image

Examples

Embodiment 1

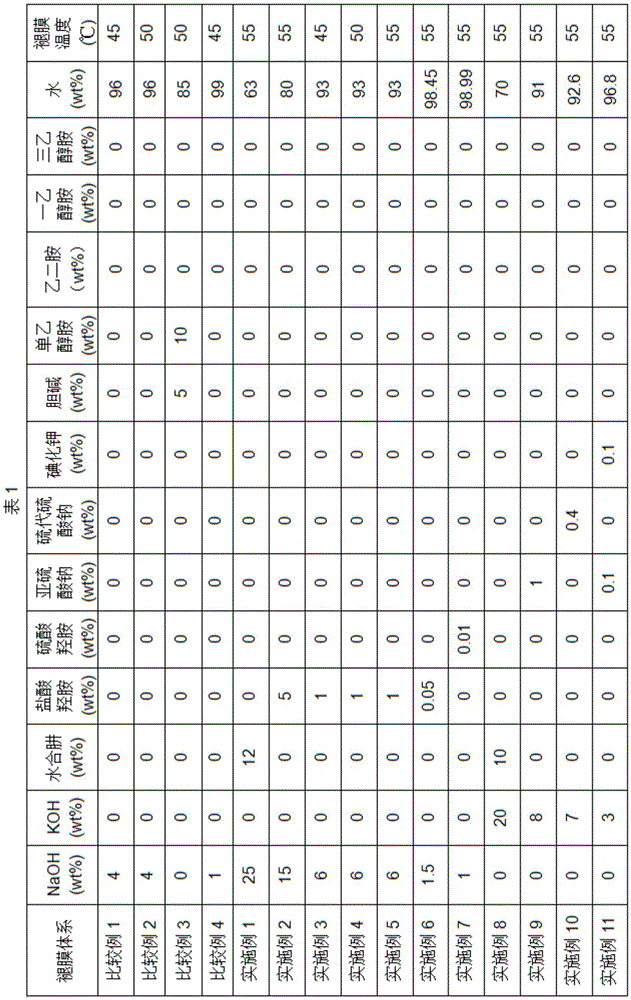

[0080] Step 1: Under normal temperature and normal pressure, dissolve the raw materials in water to prepare the stripping solution according to the composition and proportion of the stripping solution specified in Table 1;

[0081] Step 2: Pour the stripping solution obtained in step 1 into the stripping solution cylinder on the printed circuit board stripping machine; set the temperature of the stripping cylinder to the value specified in Table 1, and set the pressure of the stripping solution nozzle to Set to 1.5kg / cm 2 , start the stripping operation.

[0082] According to the method described above, measure the time when the resist layer is completely peeled off when using the film stripping solution to strip the film, observe the state of the copper surface after stripping the film completely, measure twice the COD of the film stripping waste liquid, and corresponding The results are recorded in Table 3.

Embodiment 2~20

[0084] Following the specified stripping solution components and proportions in Table 1, repeat the method of Example 1 to prepare the stripping solution. After the preparation is completed, according to the method described above, measure the time when the resist layer is completely peeled off when using the stripping solution to strip the film, observe the state of the copper surface after stripping the film completely, and measure the COD of the stripping waste liquid twice , and record the corresponding results in Table 3.

Embodiment 21

[0086] Step 1: Under normal temperature and pressure, dissolve the raw materials in water to prepare the film-removing concentrate according to the composition and proportion of the film-removing concentrated solution specified in Table 2;

[0087] Step 2: Dissolve the stripping concentrate in water to prepare the stripping solution at normal temperature and pressure, according to the dilution ratio of the stripping concentrate specified in Table 2;

[0088] Step 3: Pour the stripping solution obtained in step 2 into the stripping solution cylinder on the printed circuit board stripping machine, set the temperature of the stripping cylinder to the value specified in Table 2, and set the pressure of the stripping solution nozzle to Set at 1.5kg / cm 2 .

[0089] According to the method described above, measure the time when the resist layer is completely peeled off when using the film stripping solution to strip the film, observe the state of the copper surface after stripping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com