Solid oxide fuel cell based on semiconductor junction effect and preparation method of solid oxide fuel cell

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems such as complex process, electrical interface transportation loss, and impact on battery operating life, so as to simplify the preparation process and reduce the Production cost, effect of reducing interface transport loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 fuel cell

[0030] Taking TDC+Co and LNCA as an example to illustrate the preparation method of this battery.

[0031] Weigh 0.2g TDC+Co sample and 0.2g LNCA; prepare two foamed nickel discs with a diameter of 12.8 mm and a thickness of 1 mm; fill them in the order of foamed nickel discs, TDC+Co samples, LNCA, and foamed nickel discs In a stainless steel mold with a diameter of 13mm, ensure that the sample is evenly spread; dry press molding under a pressure of 200-300MPa, and a finished fuel cell can be obtained.

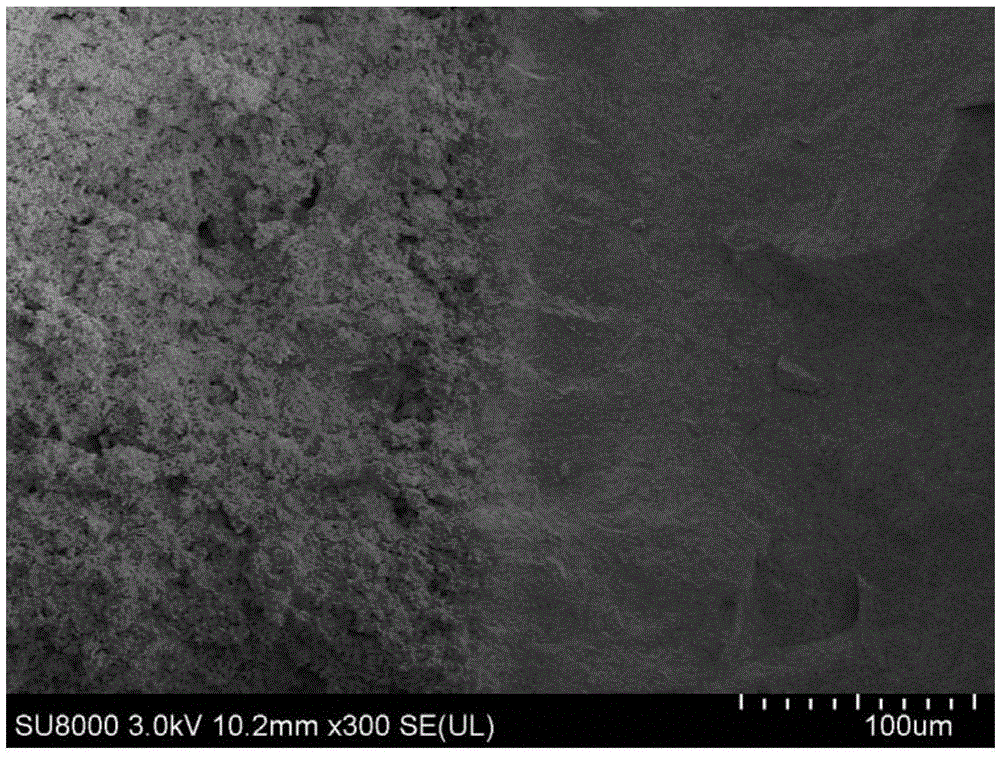

[0032] Please refer to figure 1 , figure 1 Middle is the cross-sectional electron microscope diagram of the solid oxide fuel cell based on the semiconductor junction effect of the present invention. In the figure, it can be clearly seen that the cell is composed of two layers, the loose layer (ie, the left side) is the LNCA layer, and the dense layer is the LNCA layer. TDC+Co layer, the interface between the two layers is c...

Embodiment 2

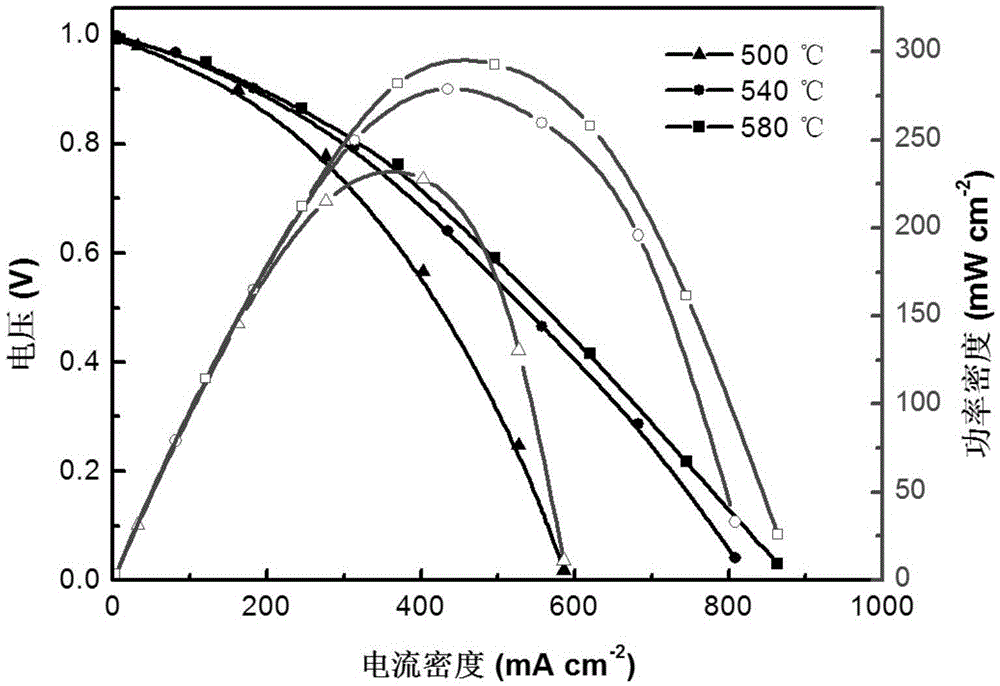

[0034] Performance test of embodiment 2 fuel cell

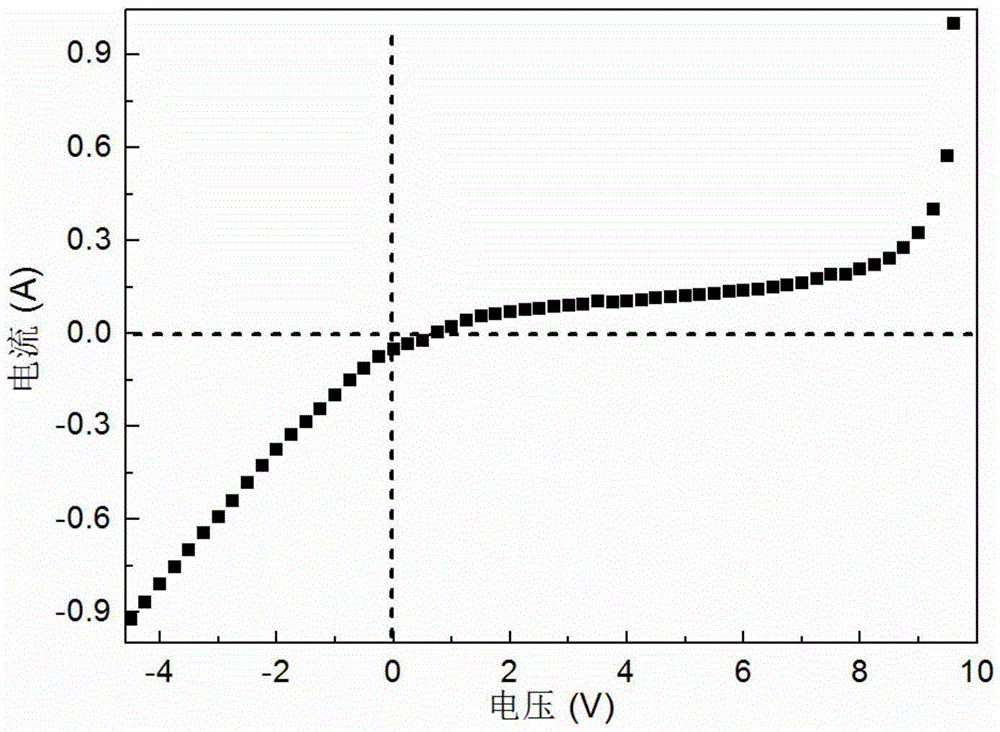

[0035]The single cell obtained in Example 1 is packaged on an alumina tube, and in the temperature range of 400-580 degrees Celsius, the fuel gas (such as hydrogen) and air are respectively passed through the LNCA side and the TDC+Co side of the battery to obtain a stable power output. The specific working principle of the battery is as follows: LNCA is the positive electrode material of the lithium battery. In the lithium battery, lithium ions can move freely in the layered structure of LNCA, thereby ensuring the free migration of lithium ions and realizing the charging and discharging process of the lithium battery; In fuel cells, nickel and cobalt components have very good catalytic activity for fuel molecules (such as hydrogen), and the protons produced by catalysis are smaller than lithium ions, so the protons produced can also move freely in the layered structure of LNCA , so as to realize the fuel cell anode half reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com