High-frequency ultrasonic atomization particle preparation system with dynamic monitoring

A preparation system and dynamic monitoring technology, applied in spray evaporation, chemical/physical processes, chemical instruments and methods, etc., can solve the problems of inability to remove highly toxic substances, cumbersome and complicated preparation process, poor water solubility, etc., to avoid multiple times Repetition of labor to achieve the effect of high-speed data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

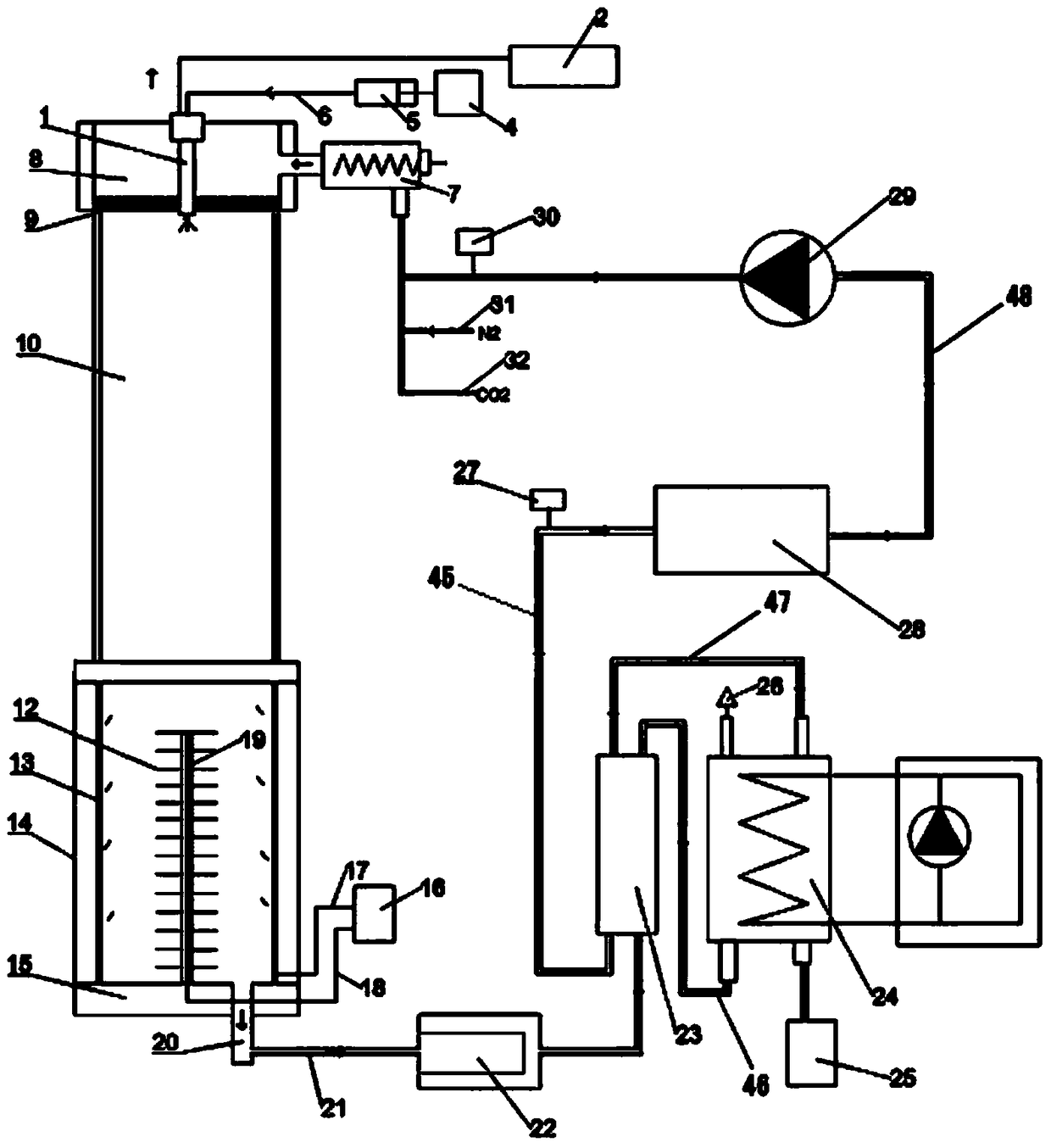

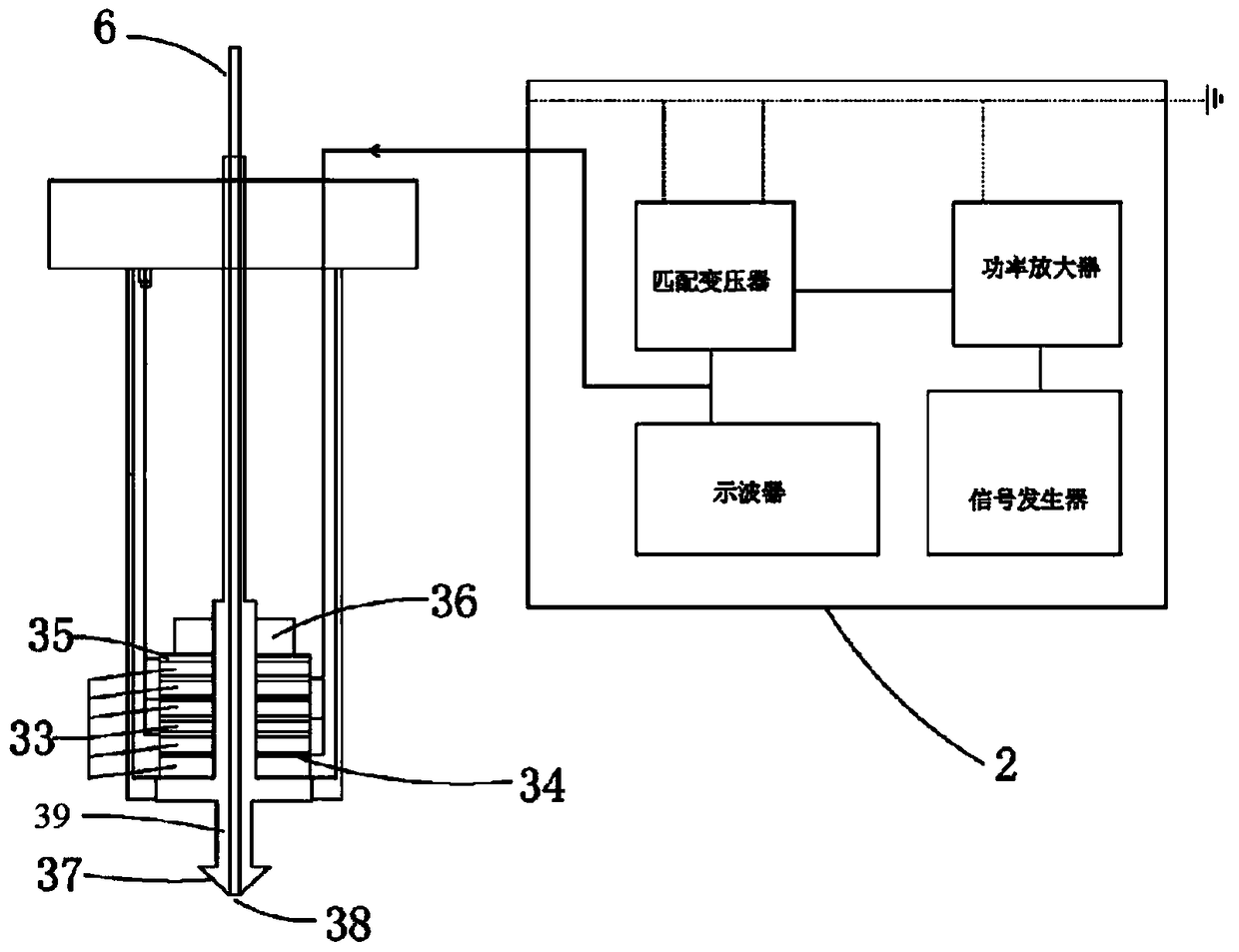

[0063] Such as figure 1 As stated, the high-frequency ultrasonic nano-atomized particle preparation system described in this application includes: a high-frequency ultrasonic nano-atomized device; a multi-point dynamic nano-particle real-time particle size and shape monitoring device; a high-efficiency laminar flow electrostatic collection device; an inert gas circulation and Organic solvent recovery device; and automatic control and data integration processing device, wherein the liquid (solution, suspension or colloidal solution) can be atomized into nano-scale droplets through the high-frequency ultrasonic nano-atomization device; in the drying chamber 10 through the layer The blowing of flow drying gas is dried into solid particles 42, and the solid particles 42 are collected in the electrostatic collector by the principle of corona effect; the gas can remove the organic solvent after the organic solvent recovery system, and realize the recycling of the inert gas; The mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com