A treatment and reuse method of shock-light wastewater and its application

A treatment method and wastewater technology, which is applied in the treatment and reuse of Zhenguang wastewater, can solve the problems that solid particles cannot be removed, can not be used in the workshop, and Ni ions are difficult to reach, so as to achieve stable discharge standards and occupy an area of Less, avoid the effect of easy poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

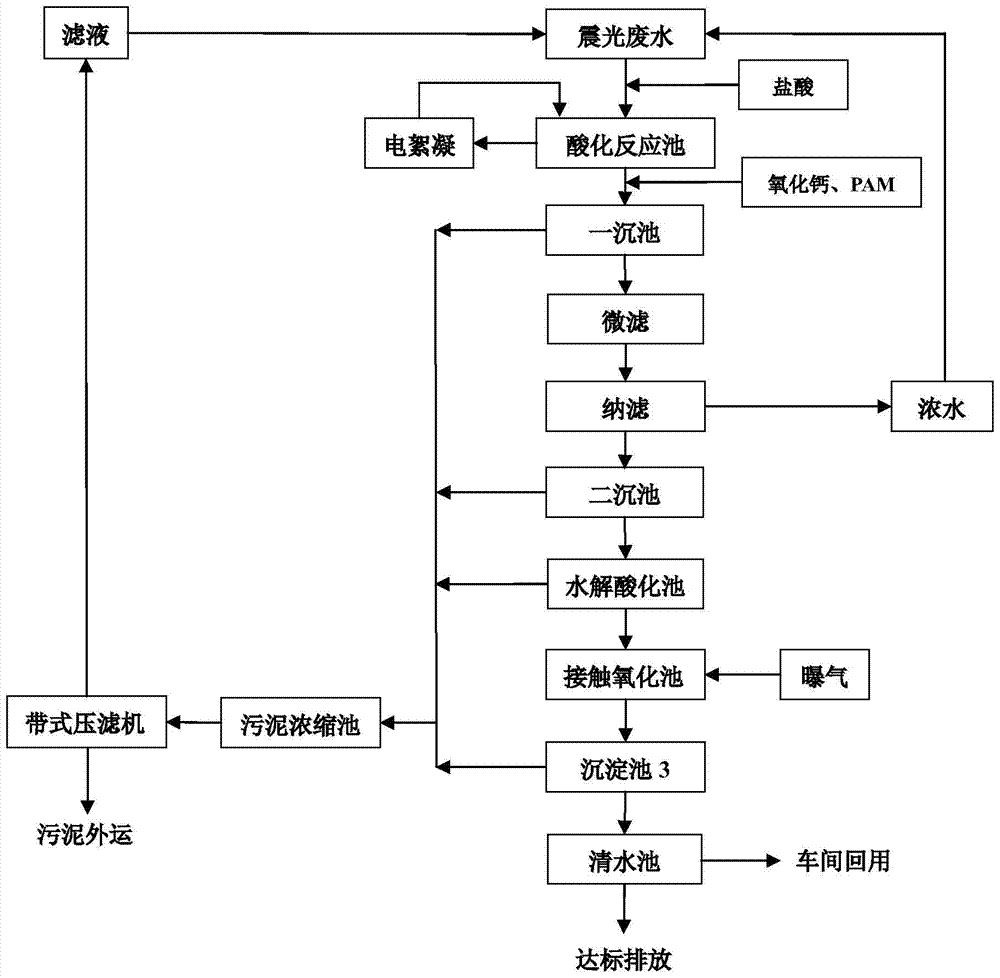

[0089] The process flow chart of the inventive method is as figure 1 As shown, the following combination figure 1 The method of the present invention is described in detail.

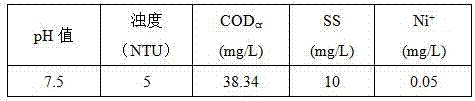

[0090] The amount of shocking wastewater from a tool manufacturing company in Hangzhou with high carbon steel is 20m 3 / d, the continuous operation time is 16 hours a day, the waste water has high heavy metal content (especially Cr and Ni in the waste water are difficult to handle), high turbidity, and poor biodegradability. The main water quality indicators of the raw water are as follows:

[0091] 1)

[0092] 2) Pump 20m into the reaction pool 3 For shocking wastewater, start the agitator, adjust the pH to 3 with hydrochloric acid, start the electrocoagulation system, control the electrode voltage to 12V, and the current density to 100A / m 2 , the acidification and electrocoagulation synergistic broken network reaction starts, and the cycle reaction is 8h;

[0093] 3) After acidification and electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com