Polylactic resin powder for selective laser sintering and a preparation method thereof

A polylactic acid resin and laser sintering technology, applied in the field of polymer processing, can solve the problems of rough surface of powder raw material particles, few polymer powder raw materials, affecting the performance of the molded body, etc., and achieve good mechanical properties, moderate size, easy The effect of dimensional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 100 parts by weight of 1510 polylactic acid resin and 1000 parts by weight of acetone were placed in an autoclave. Introduce high-purity nitrogen to 0.2MPa; then raise the temperature to 135°C, and keep the temperature at this temperature for 60 minutes; after the end of constant temperature, cool down to 100°C with cooling water at a rate of 1.0°C / min, and keep the temperature at this temperature for 60 minutes; continue Decrease to room temperature at a rate of 1.0°C / min. The polylactic acid resin powder suitable for selective laser sintering is obtained after the material is centrifugally separated and vacuum-dried.

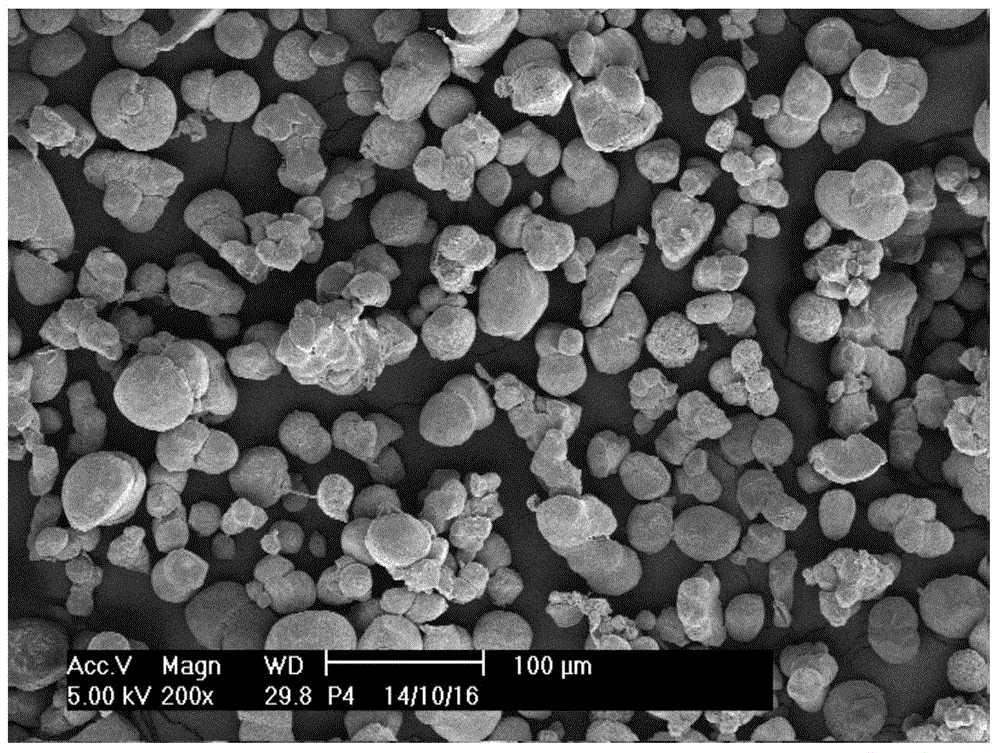

[0029] The morphology of the obtained polylactic acid resin powder was characterized by scanning electron microscopy (see the appendix figure 1 ). The particle size of the obtained polylactic acid resin powder characterized by laser particle size meter is 30-90 μm, and the particle size distribution is D10=41 μm, D50=50 μm, D90=80 μm.

Embodiment 2

[0031]100 parts by weight of 4032D polylactic acid resin and 800 parts by weight of acetone were placed in an autoclave. Introduce high-purity nitrogen to 0.1MPa; then raise the temperature to 140°C, and keep the temperature at this temperature for 30 minutes; after the end of the constant temperature, cool down to 95°C with cooling water at a rate of 1.0°C / min, and keep the temperature at this temperature for 75 minutes; Decrease to 20°C at a rate of 1.0°C / min and hold at 20°C for 60 minutes. The polylactic acid resin powder suitable for selective laser sintering is obtained after the material is centrifugally separated and vacuum-dried.

[0032] The morphology of the obtained polylactic acid resin powder was characterized by a scanning electron microscope (the result is similar to that of Example 1, and the SEM image is not shown here). As measured by a laser particle size analyzer, the polylactic acid resin powder obtained in this example has a particle size of 30-100 μm, ...

Embodiment 3

[0034] 100 parts by weight of 2002D polylactic acid resin and 1200 parts by weight of acetone were placed in an autoclave. Infuse high-purity nitrogen to 0.3MPa; then raise the temperature to 130°C, and keep the temperature at this temperature for 90 minutes; drop to room temperature at a rate of 0.1°C / min. The polylactic acid resin powder suitable for selective laser sintering is obtained after the material is centrifugally separated and vacuum-dried.

[0035] The morphology of the obtained polylactic acid resin powder was characterized by a scanning electron microscope (the result is similar to that of Example 1, and the SEM image is not shown here). As measured by a laser particle size analyzer, the particle size of the polylactic acid resin powder obtained in this example is 20-120 μm, and the particle size distribution is D10=30 μm, D50=67 μm, D90=105 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com