Processing method by shale oil through catalytic cracking

A catalytic cracking and shale oil technology, which is applied in the field of efficient utilization of shale oil resources, can solve the problems of high content and low conversion efficiency, and achieve the effects of high conversion rate, no hydrogen consumption, and long-term continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

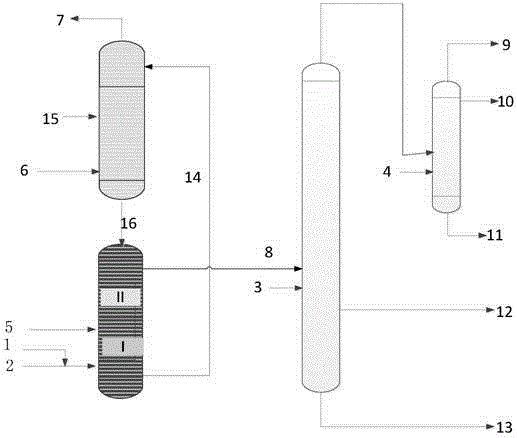

[0074] according to figure 1 shale oil A is used as the raw material for catalytic cracking, and the test is carried out on a turbulent fluidized bed reactor. Contact with catalyzer countercurrent, adopt CAT-4 catalyzer, inject a small amount of water between adsorption zone and cracking zone as cooling medium (the reactor internal diameter of adsorption zone is identical with the reactor internal diameter of described cracking zone, and the length of described adsorption zone is 40% of the length of the cracking zone). After being preheated at 240°C, shale oil A enters the bottom of the adsorption zone at the lower part of the fluidized bed reactor. With the steam fluidization medium flowing from bottom to top, at the adsorption temperature of 280°C, the cold catalyst (the first catalytic cracking catalyst) and the The weight ratio of shale oil is 8, the pressure is 0.4MPa, and the adsorption time is 120s. The adsorption reaction is carried out to remove impurities such as b...

Embodiment 2

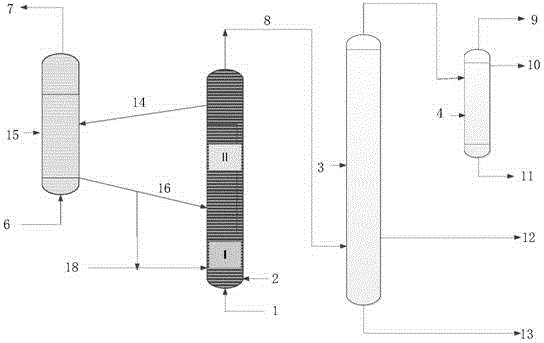

[0088] according to figure 2 The process of shale oil B is used as the raw material for catalytic cracking, and the test is carried out on the turbulent fluidized bed reactor. The reactor and the regenerator are arranged side by side, and the shale oil and the catalyst are in contact with the flow. Catalyst, in addition to introducing the hot regenerant from the external regenerator, fresh catalyst at room temperature is introduced into the adsorption zone to obtain a cold catalyst with high adsorption capacity (the first catalytic cracking catalyst). After being preheated at 300°C, shale oil B enters the bottom of the adsorption zone at the lower part of the fluidized bed reactor. With the steam fluidized medium flowing from bottom to top, at the adsorption temperature of 400°C, the weight ratio of cold catalyst to shale oil B 5.0, the pressure is 0.2MPa, and the adsorption time is 120s, and the adsorption reaction is carried out to remove impurities such as basic nitrides, ...

Embodiment 3

[0090] Carry out catalytic cracking according to the method identical with embodiment 2, difference is: introduce the fresh catalyst that exchanges heat with hot regenerative catalytic cracking catalyst as the first catalytic cracking catalyst in the adsorption zone at the bottom of the reactor, operating conditions and product distribution are listed in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com