Preparation method of porous nano CuFe2O4

A cufe2o4, nanotechnology, applied in the field of photocatalytic materials, to achieve the effect of improving photocatalytic efficiency, controllable structure, and no template residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

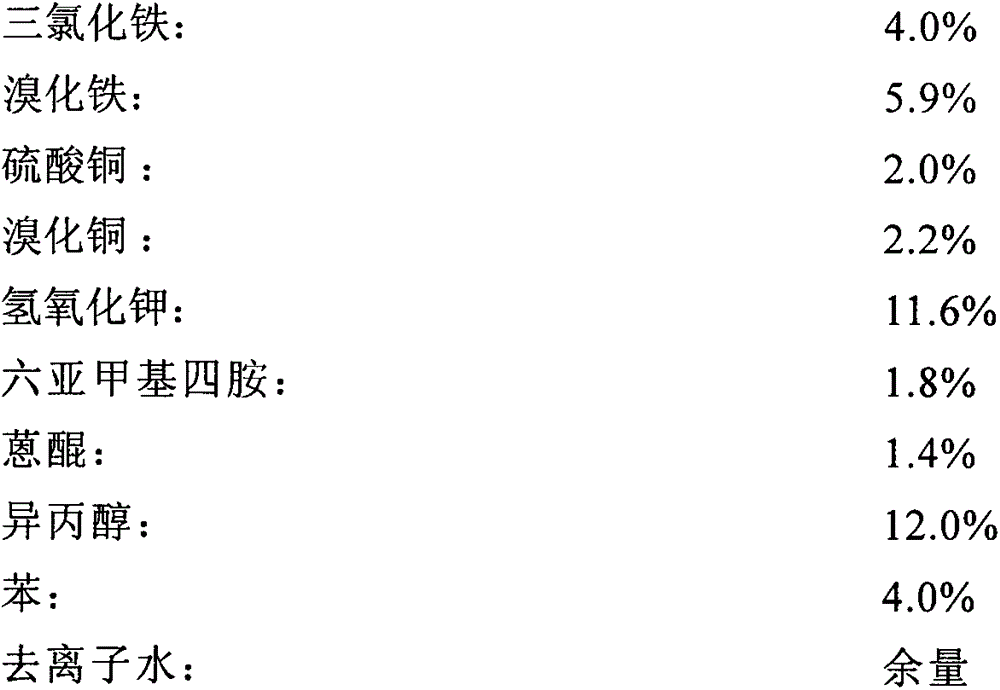

[0020] Porous Nano CuFe 2 o 4 Preparation of:

[0021]

[0022] According to the above mass percentage, ferric trichloride, ferric bromide, copper sulfate, copper bromide and half of the total amount of deionized water are mixed, stirred and dissolved to obtain ferric chloride, ferric bromide, copper sulfate and copper bromide Mix the solution, mix potassium hydroxide with the other half of the total amount of deionized water, stir and dissolve to obtain a potassium hydroxide solution, add the mixed solution of ferric chloride, ferric bromide, copper sulfate and copper bromide dropwise to hydrogen In the potassium oxide solution, after the dropwise addition, continue to stir and react for 3 hours, and the product is subjected to centrifugation and washing operations and repeated three times, and then centrifuged to obtain CuFe 2 o 4 Sol; by CuFe 2 o 4 After mixing the sol and deionized water at a mass ratio of 1:5, disperse for 2 hours with an ultrasonic wave with a fr...

Embodiment 2

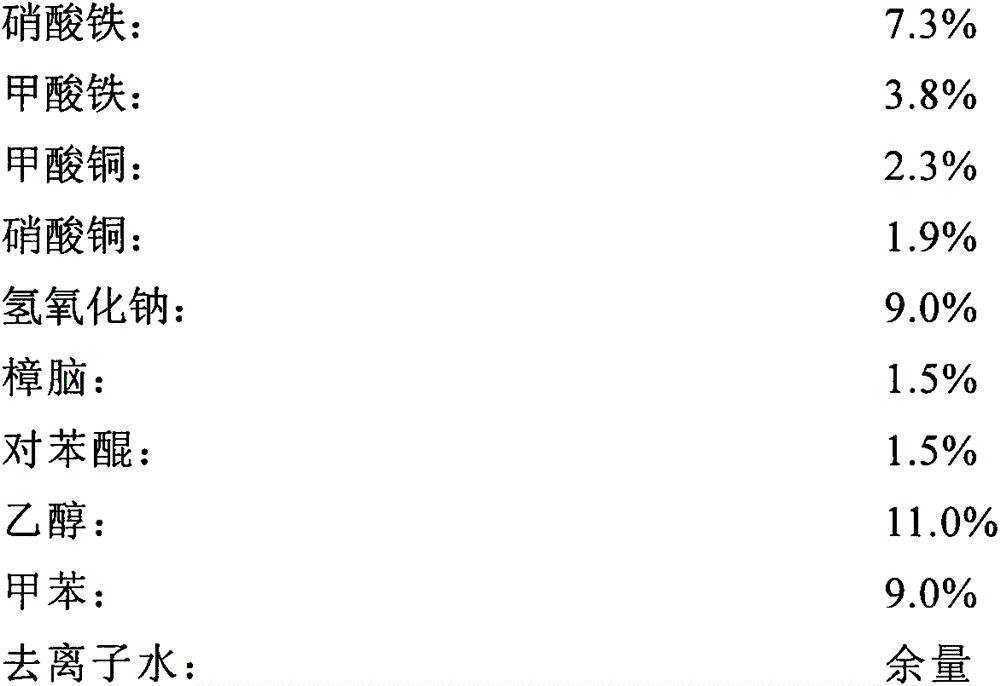

[0024] Porous Nano CuFe 2 o 4 Preparation of:

[0025]

[0026] According to the above mass percentage, iron nitrate, iron formate, copper formate and copper nitrate are mixed with half of the total amount of deionized water, stirred and dissolved to obtain a mixed solution of iron nitrate, iron formate, copper formate and copper nitrate, sodium hydroxide and The other half of the total amount of deionized water is mixed, stirred and dissolved to obtain a sodium hydroxide solution, and the mixed solution of ferric nitrate, ferric formate, copper formate and copper nitrate is added dropwise to the sodium hydroxide solution under stirring, and the stirring reaction is continued after the dropwise addition 2.5h, the product was centrifuged and washed and repeated three times, and then centrifuged to obtain CuFe 2 o 4 Sol; by CuFe 2 o 4 After mixing the sol and deionized water at a ratio of 1:8, disperse with an ultrasonic wave with a frequency of 68KHz and a power of 3KW ...

Embodiment 3

[0028] Porous Nano CuFe 2 o 4 Preparation of:

[0029]

[0030]

[0031] According to the above mass percentage, iron sulfate, iron citrate, copper chloride and copper acetate are mixed with half of the total amount of deionized water, stirred and dissolved to obtain a mixed solution of iron sulfate, iron citrate, copper chloride and copper acetate, and Lithium hydroxide and barium hydroxide are mixed with the other half of the total amount of deionized water, stirred and dissolved to obtain a mixed solution of lithium hydroxide and barium hydroxide, and the mixed solution of iron sulfate, iron citrate, copper chloride and copper acetate is stirred Add dropwise into the mixed solution of lithium hydroxide and barium hydroxide, continue to stir and react for 1.5h after the dropwise addition, the product is centrifuged and washed and repeated three times, and then centrifuged to obtain CuFe 2 o 4 Sol; by CuFe 2 o 4 After mixing the sol and deionized water at a mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com