Process for treating polluted acid water in copper smelting by utilizing calcium and magnesium desulfurization sludge

A magnesium-based desulfurization and sludge treatment technology, applied in water/sludge/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Problems such as expansion of the warehouse occur, and the effects of significant economic and environmental benefits, saving processing costs and reducing expenses are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

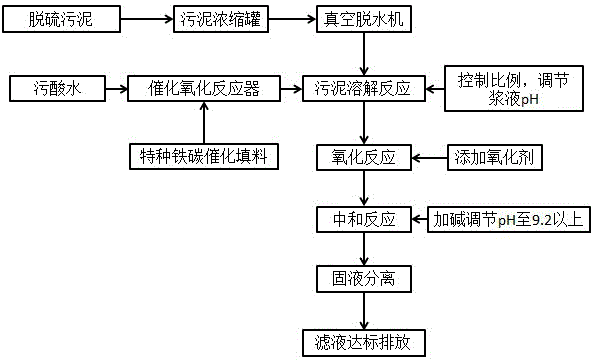

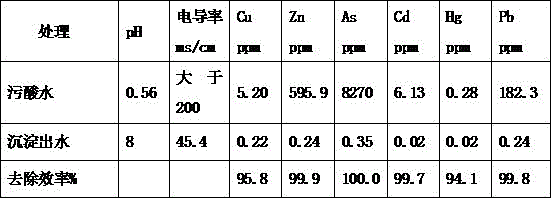

[0041] Such as figure 1 Schematic diagram of the flow shown: Take the sewage acid water of Tongling Jinlong Copper Industry in Anhui Province and the desulfurization sludge produced by magnesium desulfurization in its factory. The pH of the sewage acid water is 0.56, and the pollution factors contained in the sewage acid water include arsenic, copper, and zinc. , cadmium, etc. After the desulfurization sludge is concentrated, the moisture content is reduced to about 60%. Put the polluted acid water directly into the pretreatment reactor containing 10% lanthanum chloride, 80% iron and 10% carbon sintered at a high temperature of 990 degrees. The reaction time is 30 minutes, and the effluent and concentrated The final sludge (calculated with a water content of 60%) was mixed according to the mass ratio of 1:0.8, stirred for 40 minutes, and the pH of the slurry was maintained between 2-4. The main reactions that occurred were:

[0042] MgSO 3 +H 2 SO 4 → MgSO 3 +SO 2 +H 2 ...

Embodiment 2

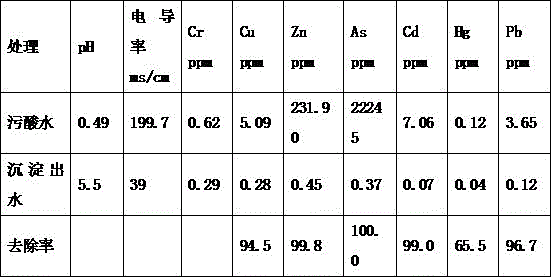

[0056] Such as figure 1 Schematic diagram of the flow shown: Take the sewage acid water of Tongling Jinlong Copper Industry in Anhui Province and the desulfurization sludge produced by magnesium desulfurization in its factory. The pH of the sewage acid water is 0.56, and the pollution factors contained in the sewage acid water include arsenic, copper, and zinc. , cadmium, etc. After the desulfurization sludge is concentrated, the moisture content is reduced to about 60%. Put the polluted acid water directly into the pretreatment reactor containing special iron-carbon fillers loaded with 30% cerium chloride, 50% iron and 20% carbon and sintered at a high temperature of 990 degrees. The reaction time is 20 minutes, and the effluent Mix with concentrated sludge (based on water content of 60%) according to the mass ratio of 1:1.0, stir for 40 minutes, maintain the pH of the slurry between 2-4, add 10% oxidant hydrogen peroxide, and stir for 90 minutes , then add calcium oxide to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com