Synthetic method of sucrose polyoxypropylene

A polyoxypropylene ether and synthesis method technology, applied in the field of organic compounds, can solve problems such as uneven mixing of materials, residual propylene oxide, dark product color, etc., to reduce color deepening, increase yield, and save production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

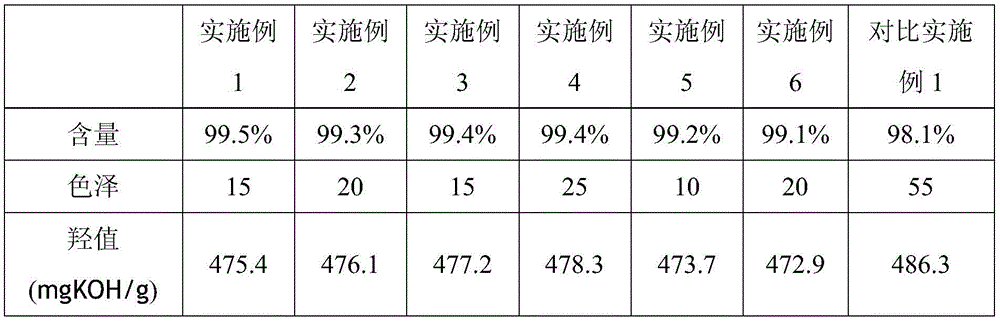

Examples

Embodiment 1

[0036] In the reaction kettle, add 513g of sucrose, 1.5g of boron trifluoride ether, and 500g of diethylene glycol diethyl ether. 2 The air in the reaction kettle was replaced, and after three replacements, the temperature was raised to 110 °C under nitrogen protection, and kept for 4 hours. After the material in the kettle was completely melted, vacuumed for 15 minutes, and then the reaction temperature was controlled to 115 °C, and the pressure of the reaction kettle was -0.05 -0.4Mpa, continue to add 914g of propylene oxide, after adding, keep warm and continue the reaction until the reaction pressure no longer drops. After the reaction is completed, the temperature is lowered to 70°C, and the unreacted propylene oxide is removed by vacuum degassing. The mother liquor is gradually heated to 115°C and subjected to vacuum distillation for 9 hours to obtain the product. After the solvent vapor is cooled, it can be used again.

[0037] The product was analyzed by liquid chromat...

Embodiment 2

[0039] In the reactor, add 513g of sucrose, 1.5g of boron trifluoride ethyl ether, and 492g of diethylene glycol diethyl ether obtained by recycling are evacuated with a vacuum pump, using N 2 The air in the reaction kettle was replaced, and after three replacements, the temperature was raised to 110 °C under nitrogen protection, and kept for 4 hours. After the material in the kettle was completely melted, vacuumed for 15 minutes, and then the reaction temperature was controlled to 115 °C, and the pressure of the reaction kettle was -0.05 -0.4Mpa, continue to add 914g of propylene oxide, after adding, keep warm and continue the reaction until the reaction pressure no longer drops. After the reaction is completed, the temperature is lowered to 70°C, and the unreacted propylene oxide is removed by vacuum degassing. The mother liquor is gradually heated to 115°C and subjected to vacuum distillation for 9 hours to obtain the product. After the solvent vapor is cooled, it can be use...

Embodiment 3

[0042] In the reaction kettle, add 513g of sucrose, 1.0g of boron trifluoride ether, 510g of ethylene glycol di-n-butyl ether and evacuated with a vacuum pump, using N 2 The air in the reactor was replaced, and after three replacements, the temperature was raised to 110 °C under nitrogen protection, and kept for 4 hours. After the material in the reactor was completely dissolved, vacuumize for 15 minutes, and then control the reaction temperature to 118 °C and the pressure of the reactor at -0.05 -0.4Mpa, continue to add 914g of propylene oxide, after adding, keep warm and continue the reaction until the reaction pressure no longer drops. After the reaction is completed, the temperature is lowered to 70°C, and the unreacted propylene oxide is removed by vacuum degassing. The mother liquor is gradually heated to 120°C and subjected to vacuum distillation for 9 hours to obtain the product. After the solvent vapor is cooled, it can be used again.

[0043] The product was analyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com