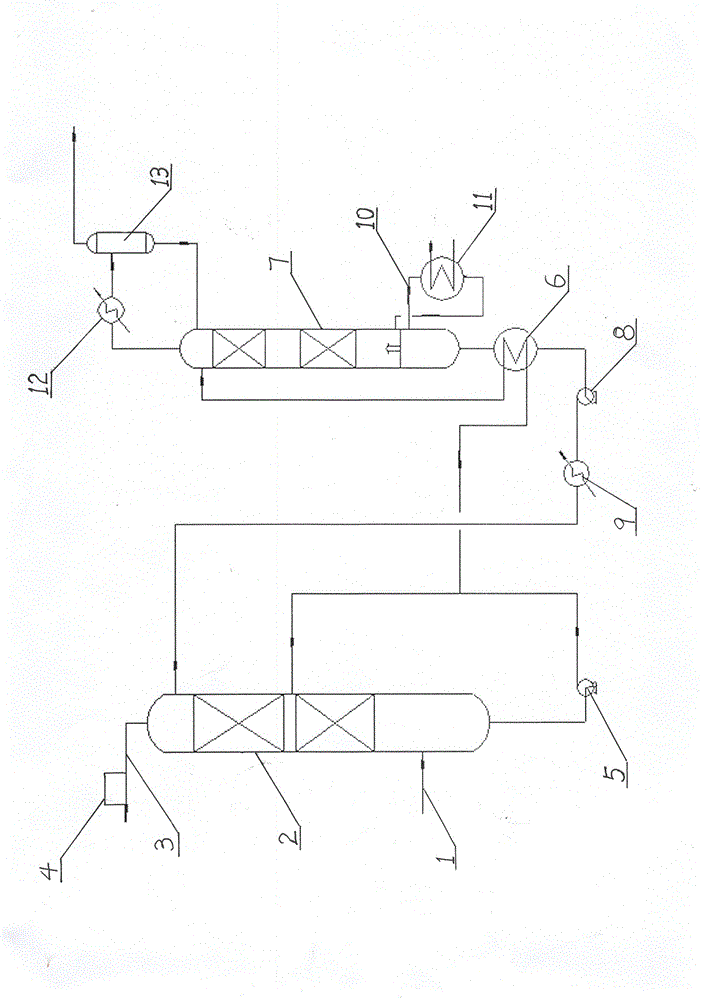

Exhaust gas desulfurization process

A flue gas and process technology, applied in the field of gas separation, can solve the problems of not reaching the maximum absorption capacity, increasing the regeneration heat load of the absorbent, and wasting the absorption capacity of the absorbent, so as to improve the utilization rate of the solution, reduce energy consumption, and reduce steam The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, using an organic amine solution to desulfurize a certain flue gas, SO in flue gas pipeline 2 initial raw material flue gas 2 The content is 2930mg / Nm 3 , The reabsorption ratio of the rich liquid is 40%, and the regeneration heat is 30% lower than the conventional process.

Embodiment 2

[0023] Example 2, using a citrate solution to desulfurize a certain flue gas, the SO in the raw flue gas 2 The content is 1790mg / Nm 3 , The reabsorption ratio of the rich liquid is 45%, and the regeneration heat is 36% lower than the conventional process.

[0024] Example 2, using a phosphate solution to desulfurize a certain flue gas, the SO in the raw flue gas 2 The content is 32500mg / Nm 3 , the reabsorption ratio of the rich liquid is 20%, and the regeneration heat is 15% lower than the conventional process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com