Method for preparing ion exchange membrane

A technology of ion-exchange membranes and membranes, which is applied in the field of preparation of ion-exchange membranes. It can solve the problems of uneven heating of membranes, large investment in equipment and equipment, high safety and technical requirements, and achieve uniform membrane thickness, fast production speed, and low technical difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

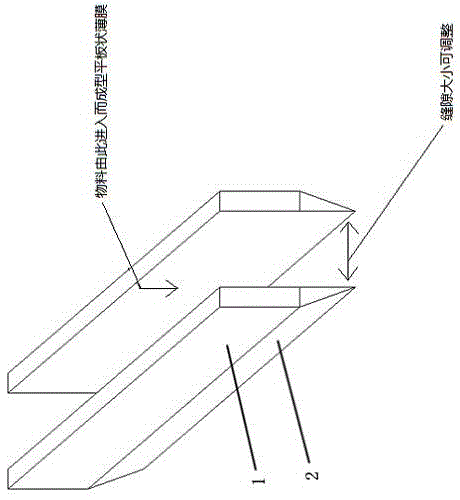

[0027] Embodiment 1: the preparation method of a kind of ion exchange membrane of this example, its step is: adopt 65 weight parts acrylic acid, 5 weight parts divinylbenzene, 9 weight parts 2,4,6-trimethylbenzoyl diphenyl Phosphine oxide, 3 parts by weight of ethylene-propylene rubber, 8 parts by weight of chlorinated polyethylene, and 10 parts by weight of terpene resin. After the polymerization inhibitor is removed from the above raw materials, they are mixed evenly in the dark, left to stand for defoaming, and put into flat plate molding device, such as figure 1 , The molding device includes two symmetrically arranged molding boards 1, the outer surface of the lower end of the molding board shrinks into an inclined plane 2, and a gap for feeding materials is formed between the two molding boards. The mixed material flows out under pressure through the narrow gap of the device. The gap between the narrow gaps is 0.5mm. After the material flows out, it enters the ultraviolet...

Embodiment 2

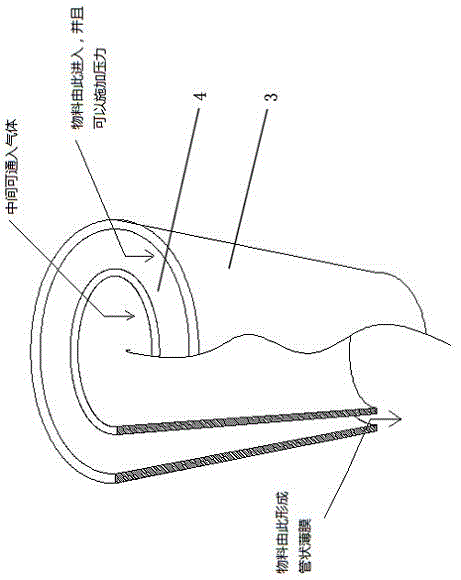

[0028] Embodiment 2: the preparation method of a kind of ion exchange membrane of this example, its step is: adopt 60 parts by weight styrene, 5 parts by weight divinylbenzene, 5 parts by weight 2,4,6-trimethylbenzoyl di Phenylphosphine oxide, 15 parts by weight of linear low-density polyethylene, 10 parts by weight of ethylene-propylene rubber, and 5 parts by weight of styrene-butadiene-styrene block copolymer, after removing the polymerization inhibitor, the above raw materials are mixed in the dark Evenly, let it stand for degassing, and put it into a ring-shaped molding device, such as figure 2 , the molding device includes an outer tube 3 and an inner tube 4, the diameters of the outer tube and the inner tube gradually decrease from top to bottom, there is a gap for feeding materials between the outer tube and the inner tube, and there is a gap inside the inner tube A hole through which gas can pass. The mixed material passes through the narrow gap of the device, with a...

Embodiment 3

[0029] Embodiment 3: the preparation method of a kind of ion exchange membrane of this example, its step is: adopt 60 weight parts glycidyl methacrylate, 10 weight parts divinylbenzene, 8 weight parts benzoin ethyl ether, 8 weight parts Linear low-density polyethylene, 8 parts by weight of styrene-butadiene rubber, 6 parts by weight of ethylene dichloride, and the above raw materials are removed from the polymerization inhibitor, mixed evenly in the dark, and packed into a flat-plate molding device, such as figure 1, The molding device includes two symmetrically arranged molding boards 1, the outer surface of the lower end of the molding board shrinks into an inclined plane 2, and a gap for feeding materials is formed between the two molding boards. The mixed material flows out under pressure through the narrow gap of the device. The distance between the narrow gaps is 0.5mm. After the material flows out, it enters the ultraviolet light area immediately. The light time is 5 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com