High-strength novel chemical foaming cement and preparation method thereof

A chemical foaming, high-strength technology, applied in the field of building materials, can solve the problems of irregular shape, high water absorption, high cell connectivity, and achieve the effects of easy mass production, low water absorption, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

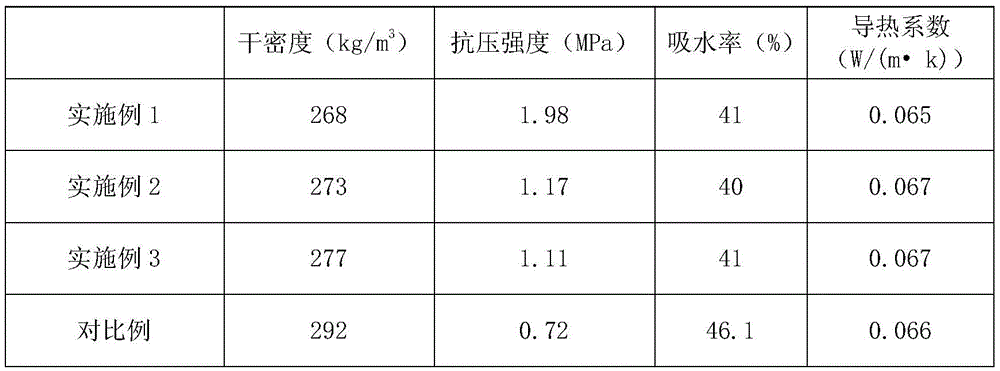

Examples

Embodiment 1

[0024] Weigh 70 parts of 42.5 ordinary Portland cement, 30 parts of secondary fly ash, 0.4 part of 9mm polypropylene fiber, 0.8 part of calcium stearate, 0.08 part of lithium carbonate, 0.1 part of sodium bisulfate, thiourea 0.2 parts, added to the mixing pot and stirred evenly to prepare the mixed material. Add 54 parts of water at 50°C to the mixed material, stir at a high speed for 2 minutes to obtain a uniform slurry; add 5 parts of a hydrogen peroxide foaming agent with a mass concentration of 30% to the slurry, and stir at a high speed for 10 seconds to obtain a mixed slurry . The mixed slurry was quickly poured into a mold, covered with a layer of plastic film, left to foam, demolded after 24 hours, placed in an oven at 50°C, and cured for 28 days to obtain a high-strength new chemical foaming cement.

Embodiment 2

[0026] Weigh 80 parts of 42.5 ordinary Portland cement, 20 parts of secondary fly ash, 0.4 part of 9mm polypropylene fiber, 0.8 part of calcium stearate, 0.08 part of lithium carbonate, 0.05 part of sodium bisulfate, thiourea 0.2 parts, added to the mixing pot and stirred evenly to prepare the mixed material. Add 51 parts of water at 50°C to the mixed material, stir at a high speed for 2 minutes to obtain a uniform slurry; add 4.8 parts of a hydrogen peroxide foaming agent with a mass concentration of 30% to the slurry, and stir at a high speed for 10 seconds to obtain a mixed slurry . The mixed slurry was quickly poured into a mold, covered with a layer of plastic film, left to foam, demolded after 24 hours, placed in an oven at 50°C, and cured for 28 days to obtain a high-strength new chemical foaming cement.

Embodiment 3

[0028] Weigh 70 parts of 42.5 ordinary Portland cement, 30 parts of secondary fly ash, 0.4 part of 9mm polypropylene fiber, 0.8 part of calcium stearate, 0.08 part of lithium carbonate, 0.15 part of sodium bisulfate, thiourea 0.225 parts, added to the mixing pot and stirred evenly to prepare the mixed material. Add 54 parts of water at 50°C to the mixed material, and stir at a high speed for 2 minutes to obtain a uniform slurry; add 5 parts of a hydrogen peroxide foaming agent with a mass concentration of 30% to the slurry, and stir at a high speed for 10 seconds to obtain a mixed slurry . Pour the mixed slurry into the mold quickly, cover with a layer of plastic film, let it stand for foaming, demould after natural curing and molding, and cure the chemical foaming cement formed by natural curing in an oven at 50°C for 28 days, A new high-strength chemical foaming cement is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com