A kind of preparation method of non-ionic water-based polythiourethane

A polythiourethane, non-ionic technology, applied in the field of water-based polyurethane, to achieve good environmental protection, excellent bonding performance, excellent ozone resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

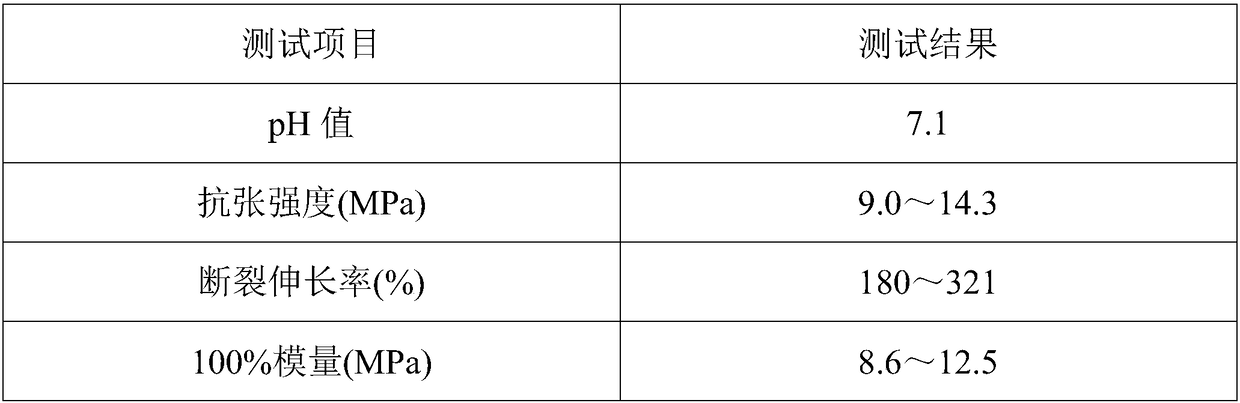

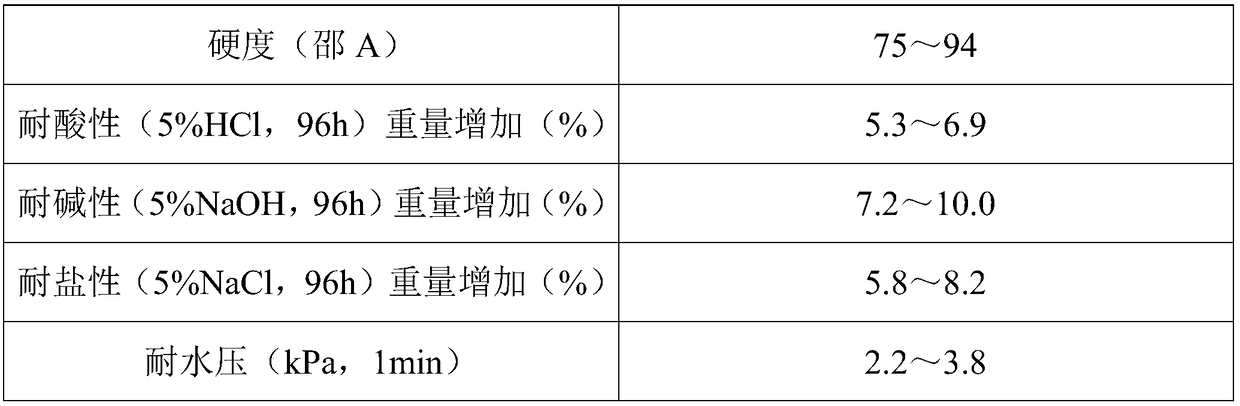

Examples

Embodiment 1

[0048] A kind of preparation method of nonionic waterborne polythiourethane that the present invention proposes, comprises the steps:

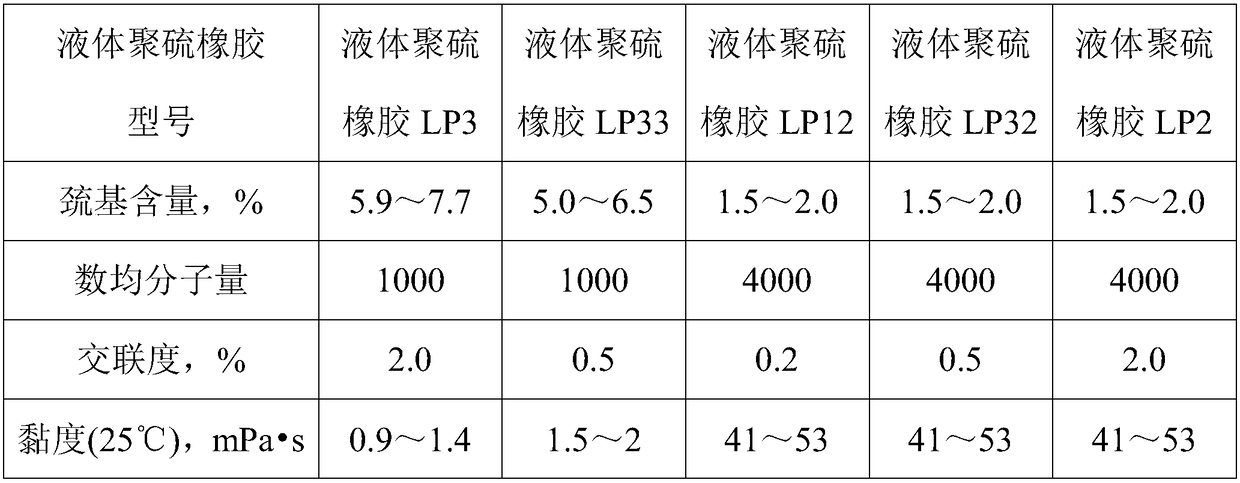

[0049] S1. Add 43.9g of isophorone diisocyanate to 15g of liquid polysulfide rubber LP3 that has been vacuum dehydrated at 110°C for 1 hour and raise the temperature to 100°C, keep it warm for 90min, cool the reaction system to 60°C with ice water, and then add A mixed solution of 8 g of trimethylolpropane-polyethylene glycol monoether with a number-average molecular weight of 1000 and 15 g of polyoxypropylene glycol with a number-average molecular weight of 1000, which was dehydrated in vacuum for 1 hour, was heated to 93°C and kept for 120 minutes to obtain a terminal isocyanate Polysulfide-based modified polyurethane prepolymer;

[0050] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, add 5.1g of diethylene glycol, 7.2g of 1,4-butanediol, 1.2g of trimethylolpropane, and 0.12g of octanoic acid Stanno...

Embodiment 2

[0053] A kind of preparation method of nonionic waterborne polythiourethane that the present invention proposes, comprises the steps:

[0054] S1. Add 61.4g of isophorone diisocyanate to 50g of liquid polysulfide rubber LP3 which has been vacuum dehydrated at 110°C for 1 hour and raise the temperature to 100°C, keep it warm for 90min, cool the reaction system to 60°C with ice water, and then add 8.9 g of trimethylolpropane-polyethylene glycol monoether with a number-average molecular weight of 1200 were vacuum-dehydrated for 1 hour, heated to 95°C, and kept for 120 minutes to obtain an isocyanate-terminated polysulfide-modified polyurethane prepolymer;

[0055] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, add 6g ethylene glycol, 6.7g neopentyl glycol, 2g glycerin, 0.12g stannous octoate and 0.15g dibutyltin dilaurate, Then add 40 mL of acetone to reduce the viscosity of the reaction system, raise the temperature to 70°C, and keep it ...

Embodiment 3

[0058] A kind of preparation method of nonionic waterborne polythiourethane that the present invention proposes, comprises the steps:

[0059] S1. Add 70.5g of dicyclohexylmethane diisocyanate to 30g of liquid polysulfide rubber LP33 which has been vacuum dehydrated at 110°C for 1 hour and heat up to 100°C, keep it warm for 90min, cool the reaction system to 60°C with ice water, and then add 20 g of polyethylene glycol with a number-average molecular weight of 1000, vacuum-dehydrated for 1 hour, heated to 95° C., and kept for 120 minutes to obtain a polysulfide-modified polyurethane prepolymer with terminal isocyanate groups;

[0060] S2. Cool the isocyanate-terminated polysulfide-modified polyurethane prepolymer to 40°C, add 5.6g 1,3-propanediol, 6.7g ethylene glycol, 1.1g pentaerythritol, 0.12g stannous octoate and 0.18g dilaurate butyl tin, then add 45mL acetone to reduce the viscosity of the reaction system, raise the temperature to 70°C, and keep it warm for 300 minutes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com