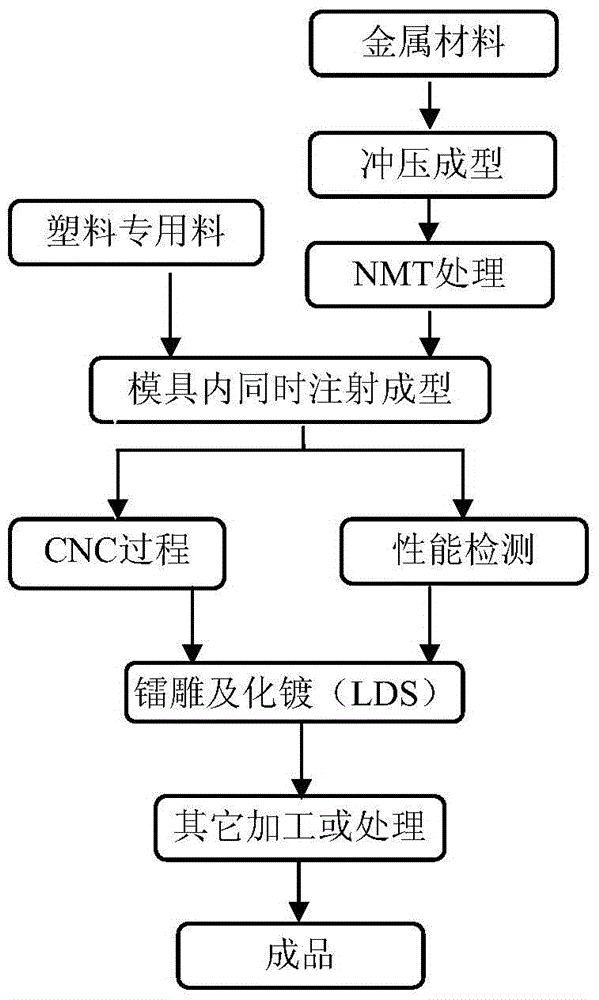

NMT polyester composition with LDS function

A technology of composition and polyester, which is applied in the field of polyester composition, can solve problems such as inability to carry out LDS, large molding shrinkage, poor acid and alkali resistance, etc., to improve the precision and accuracy of laser engraving, improve strength, and heat resistance sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

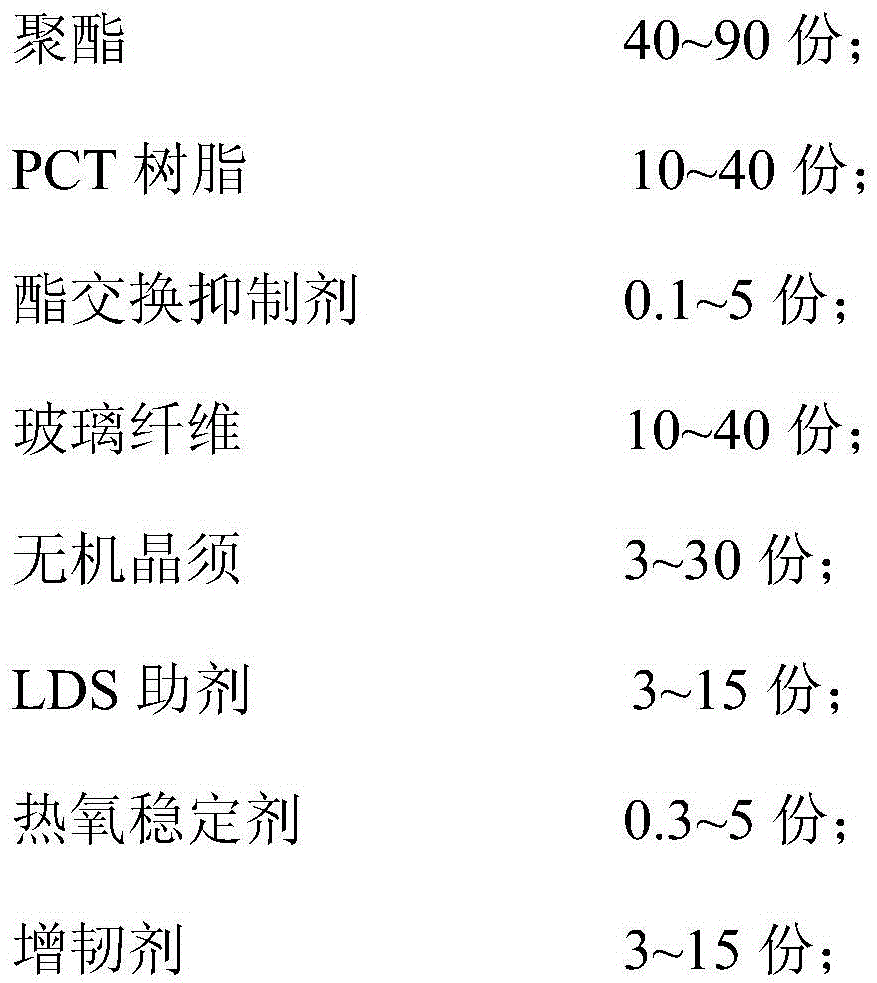

[0062] Embodiment 1: The polyester composition for NMT with LDS function of the present embodiment is mainly composed of the following raw materials in parts by mass:

[0063]

[0064] Among them, the glass fiber is an ordinary cylindrical cross-section glass fiber, and the model is 3610.

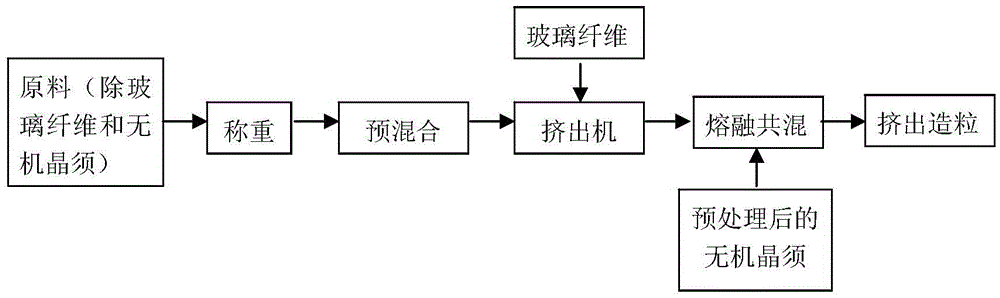

[0065] The method for preparing the above-mentioned polyester composition for NMT with LDS function is as follows:

[0066] (1) According to the above formula content, PBT resin, PCT resin, transesterification inhibitor, LDS auxiliary agent, thermal oxygen stabilizer, toughening agent and lubricant are mixed to obtain a mixture;

[0067] (2) Putting the mixture and glass fibers into an extruder, performing melt blending, adding inorganic whiskers, extruding and granulating, and obtaining a polyester composition for NMT with LDS function.

Embodiment 2

[0068] Embodiment 2: The NMT polyester composition with LDS function of the present embodiment, by mass parts, includes the following components:

[0069]

[0070]

[0071] Among them, the glass fiber is an ordinary cylindrical cross-section glass fiber, and the model is 3610.

[0072] The method for preparing the polyester composition for NMT in this example is the same as that in Example 1.

Embodiment 3

[0073] Embodiment 3: The glass fibers in this embodiment are glass fibers with equal cross-section and special-shaped cross-section, and the degree of deformation is 3:1. The inorganic whiskers are zinc oxide whiskers, ceramic whiskers or calcium sulfate whiskers, and the others are the same as in Embodiment 2.

[0074] The method for preparing the polyester composition for NMT in this example is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com