Preparation method of high-rate graphite anode material, anode material and lithium-ion battery

A graphite negative electrode and high-rate technology, applied in the field of materials, can solve the problems that affect the initial efficiency of the full battery energy density, the increase of the material specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

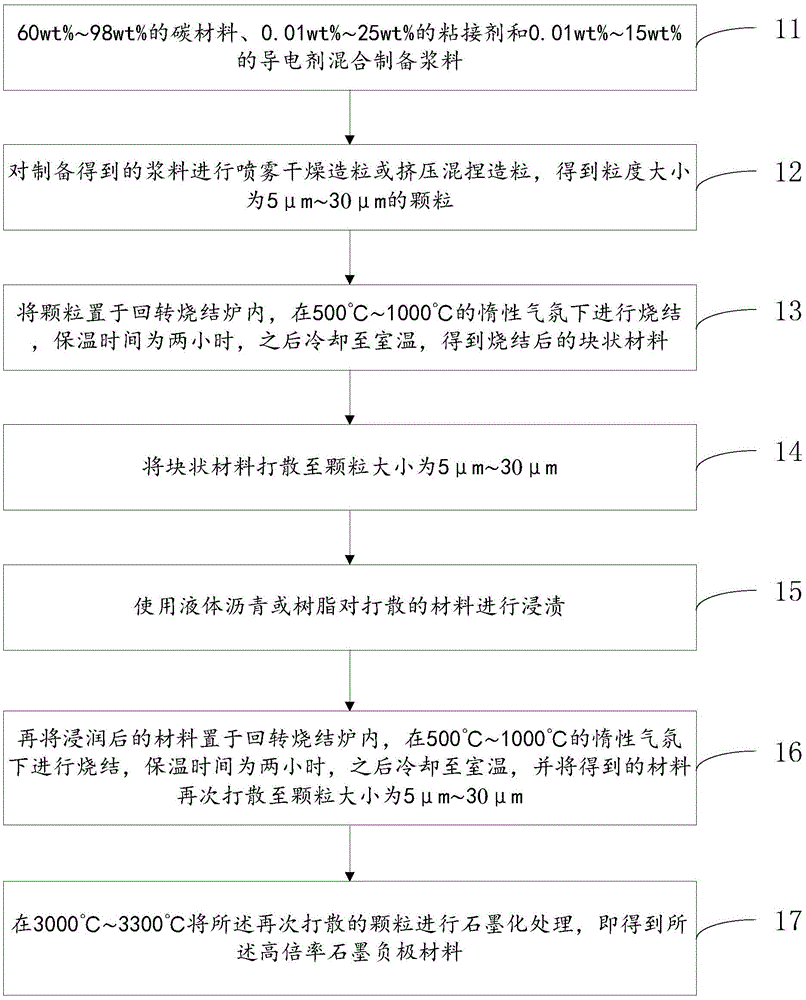

[0041] Embodiment 1 of the present invention provides a kind of preparation method of high rate graphite negative electrode material, such as figure 1 shown, including the following steps:

[0042] Step 11, mixing 60wt%-98wt% carbon material, 0.01wt%-25wt% binder and 0.01wt%-15wt% conductive agent to prepare slurry;

[0043] Specifically, the particle size of the carbon material is 0.5 μm to 10 μm, including one of natural graphite, artificial graphite, graphite powder, mesocarbon microspheres, petroleum coke, pitch coke, needle coke, coke, soft carbon or hard carbon. one or more species.

[0044] The binder includes one or more of pitch, resin, and cellulose. Wherein, the resin may include: phenolic resin, urea-formaldehyde resin, melamine-formaldehyde resin, epoxy resin, unsaturated resin, polyurethane, polyimide and the like. Cellulose may include: methylcellulose, hydroxypropylmethylcellulose, hydroxyethylcellulose, carboxymethylcellulose, and the like.

[0045] The co...

Embodiment 2

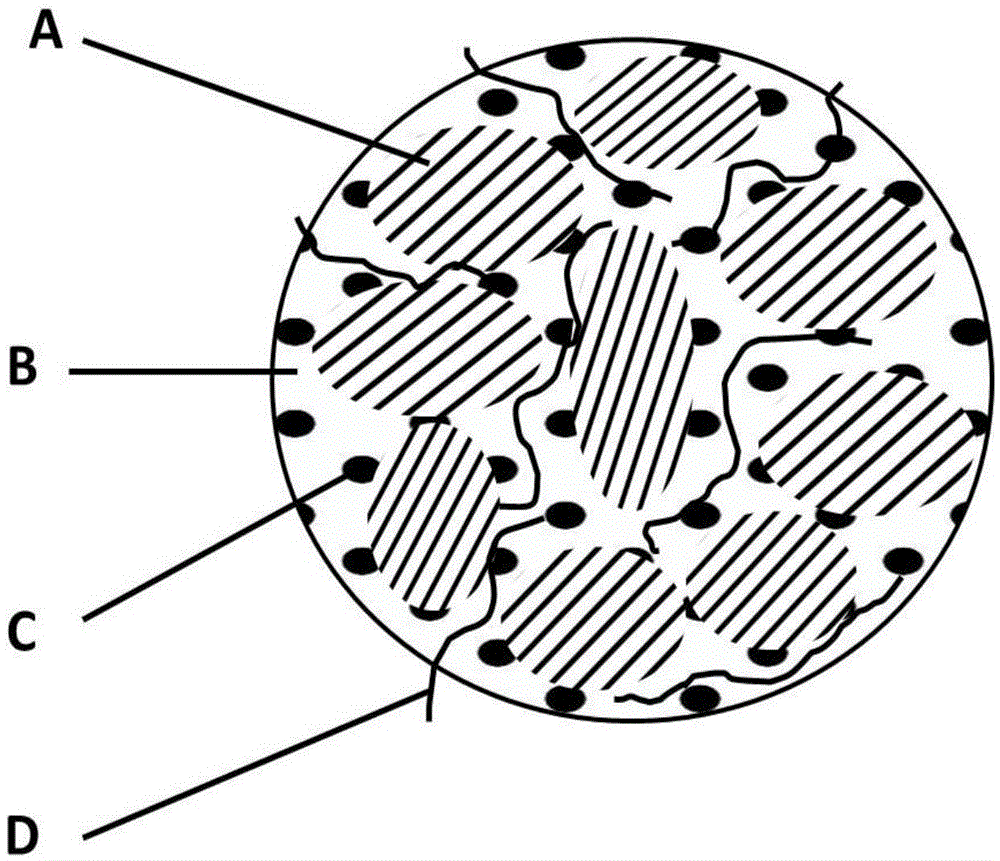

[0063] The high-magnification graphite negative electrode material prepared by the method provided in the above-mentioned embodiment 1 can be used for lithium ion battery negative electrode material, figure 2 A schematic diagram of the structure of the graphite anode material is shown in .

[0064] The material A shown in the figure includes: one or more combinations of natural graphite, artificial graphite, graphite powder, mesocarbon microspheres, petroleum coke, pitch coke, needle coke, coke, soft carbon or hard carbon; The microscopic morphology has a typical layered structure, and the layer spacing is between 0.3nm and 0.4nm; this part is the main contributor to the capacity of the negative electrode material;

[0065] The particle size distribution (D50) of the substance A is 0.5 μm to 15 μm, preferably 1 μm to 10 μm. The shape of substance A is one or more of spherical, ellipsoidal, pebble-shaped and irregular polygons; the selection of small particle size is to reduc...

Embodiment 3

[0077] Embodiment 3 of the present invention provides a specific method for preparing a high-rate graphite negative electrode material.

[0078] 78.36wt% of natural graphite, 21.46wt% of epoxy resin, 0.09wt% of carbon black, and 0.09wt% of carbon nanotubes were mixed to prepare a slurry, and the slurry was spray-dried and granulated or extruded and kneaded to granulate, To obtain particles with a particle size of 20 μm, place the particles in a rotary sintering furnace, raise the temperature from room temperature to 750 °C at a rate of 2.5 °C / min, sinter in an inert atmosphere, keep the temperature for two hours, and then cool to room temperature to obtain sintered The final block material; after the block material is broken up, soak it with liquid pitch, repeat sintering and soaking twice, and then break it down to a particle size of 20 μm; then carry out graphitization treatment at 3100 ° C to obtain high-magnification graphite Negative material.

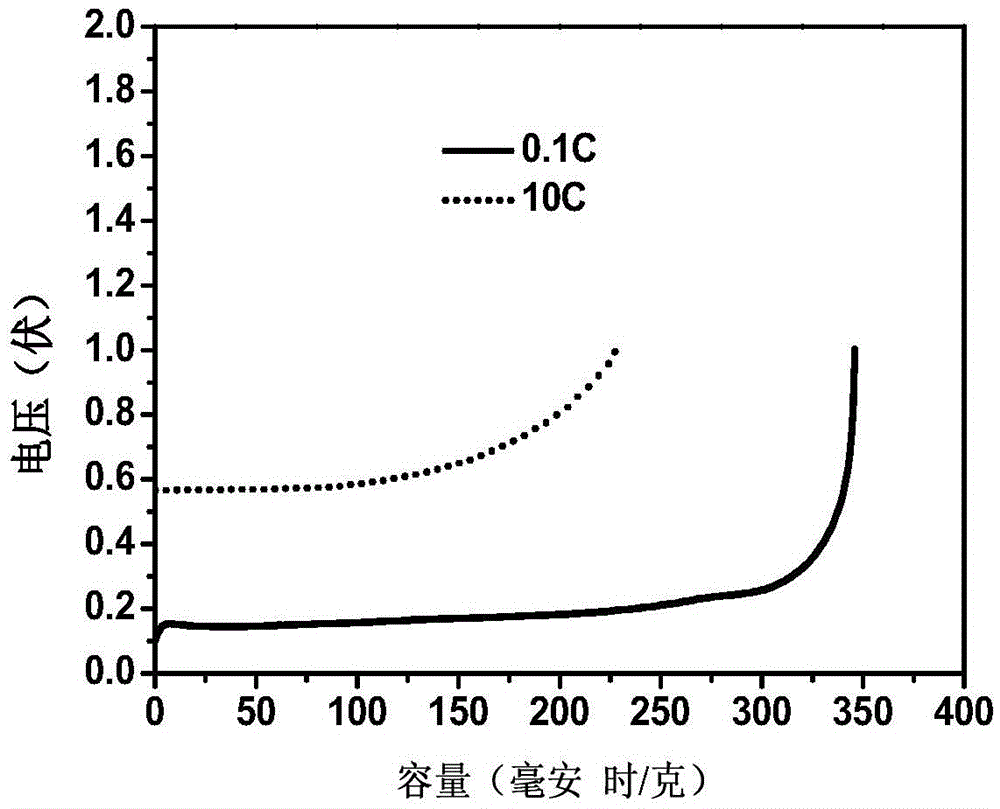

[0079] The graphite negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com