A kind of composite cerium-zirconium solid solution and preparation method thereof

A technology of cerium-zirconium solid solution and solution, which is applied in the field of composite cerium-zirconium solid solution and its preparation, can solve the problems that oxygen storage capacity and thermal stability, surface area or pore properties cannot be perfectly matched at the same time, and achieve high oxygen storage capacity and thermal stability properties, large pore size and pore volume, and simple steps in the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A composite cerium-zirconium solid solution, which is compounded by cerium oxide, zirconia and rare earth additives, and its preparation method comprises the following steps: first, add 4ml of nitric acid and 3ml of hydrogen peroxide into 150ml of deionized water to prepare a dissolved acid solution; then Add 2.44 g of cerium carbonate (CeO 2 content 41%), 4.76 grams of zirconium carbonate (ZrO 2 content 42%), 0.245 grams of praseodymium oxide and 0.245 grams of rubidium oxide, stirred and dissolved at 25 ° C to obtain a mixed solution of nitrate A; 7.5 ml of ammonia water and 1 gram of stearic acid were added to 150 ml of deionized In water, fully stir at 40°C to prepare solution B; add nitrate mixed solution A and solution B to the beaker dropwise at a speed of 2.5ml / min, and stir well; the precipitation reaction temperature is maintained at 30°C; After the addition is complete, add 3ml of hydrogen peroxide and continue to stir for 0.5 hours, and then the precipitat...

Embodiment 2

[0021] A composite cerium-zirconium solid solution, which is compounded by cerium oxide, zirconia and rare earth additives, and its preparation method comprises the following steps: first, add 4ml of nitric acid and 3ml of hydrogen peroxide into 150ml of deionized water to prepare a dissolved acid solution; then Add 2.44 g of cerium carbonate (CeO 2 content 41%), 4.76 grams of zirconium carbonate (ZrO 2 Content 42%), 0.245 grams of praseodymium oxide and 0.245 grams of rubidium oxide, stirred and dissolved at 40 ° C to obtain a mixed solution of nitrate A; 7.5 ml of ammonia water, 1.5 grams of stearic acid and 0.5 grams of polyethylene glycol Add it into 150ml of deionized water, stir well at 40°C to prepare solution B; add nitrate mixed solution A and solution B to the beaker at a speed of 2.5ml / min, and stir well; precipitation reaction temperature Maintain at 30°C; after the dropwise addition, add 5ml of hydrogen peroxide and continue to stir for 0.5 hours, then the preci...

Embodiment 3

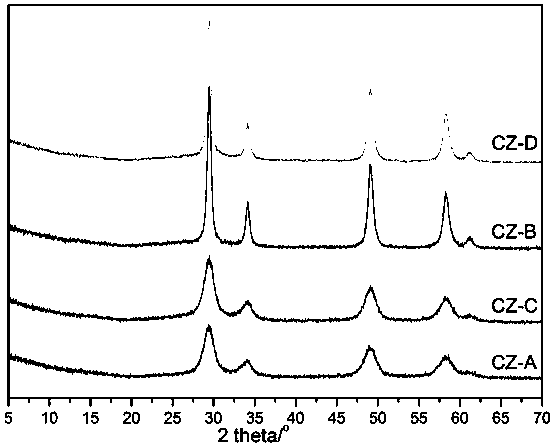

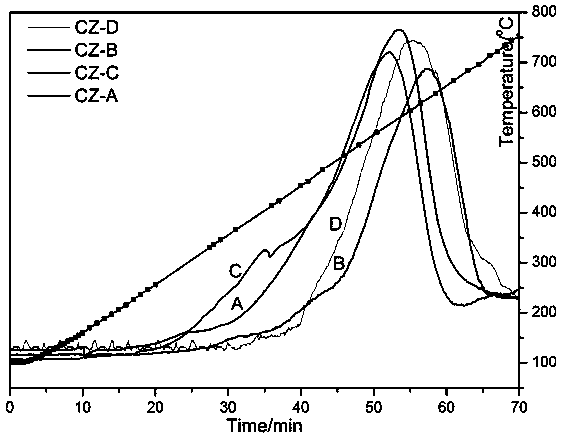

[0023] Such as Figure 1-2 As shown, a composite cerium-zirconium solid solution is composed of cerium oxide, zirconia and rare earth additives. Its preparation method includes the following steps: first, add 4ml of nitric acid and 3ml of hydrogen peroxide into 150ml of deionized water to prepare dissolved acid solution; then add 2.44 g of cerium carbonate (CeO 2 content 41%), 4.76 grams of zirconium carbonate (ZrO 2 content 42%), 0.245 grams of praseodymium oxide and 0.245 grams of rubidium oxide, stirred and dissolved at 25 ° C to obtain a nitrate mixed solution A; 7.5 ml of ammonia water, 1.5 grams of stearic acid and 0.5 grams of polyethylene glycol Add it into 150ml of deionized water, stir well at 40°C to prepare solution B; add nitrate mixed solution A and solution B to the beaker at a speed of 2.5ml / min, and stir well; precipitation reaction temperature Maintain at 30°C; after the dropwise addition, add 3ml of hydrogen peroxide and continue to stir for 0.5 hours, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com