Preparation method of hydrophobic hierarchical pore solid acid-alkali bifunctional catalyst

An acid-base bifunctional, multi-level pore technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., to achieve excellent catalytic effect, increase crosslinking degree, The effect of simple and quick separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

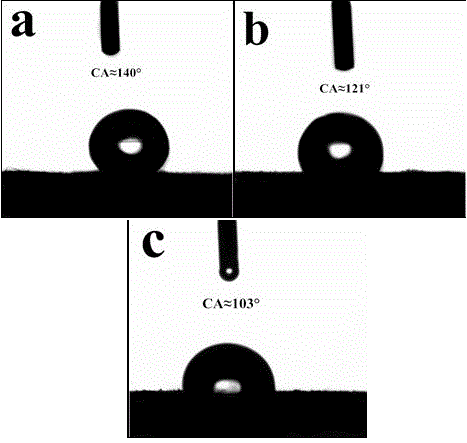

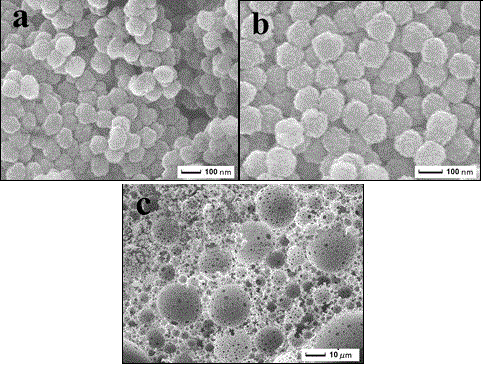

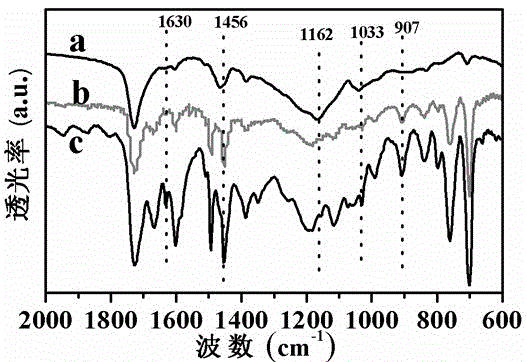

[0029] 1. A method for preparing a hydrophobic multi-level porous solid acid-base bifunctional catalyst, characterized in that it is carried out according to the following steps:

[0030] (1) Synthesis of basic functionalized hydrophobic nanoparticles

[0031] Mix 0.5 mL of glycidyl methacrylate (GMA) and 59 mL of H 2 O was added to a 250ml three-necked flask, filled with nitrogen for ten minutes, then 1.8mL of styrene (St) and 0.8mL of diethylbenzene (DVB) were added into it, then heated to 90°C, and 0.06g Potassium persulfate was stirred at 600~800rpm for 1-1.5 hours, and after high-speed centrifugation, it was dried in a vacuum oven at 40~50°C for 20~24 hours to obtain hydrophobic styrene epoxy particles (ie: S-GMA); Prepared 0.4g of hydrophobic styrene epoxy particles and 9.0mL of 22%~25% NH 3 ·H 2 O mixing, stirring at 90°C for 9-10 hours under reflux condensation, high-speed centrifugation, and drying in a vacuum oven at 40-50°C for 10-12 hours to obtain alkaline func...

Embodiment 2

[0046] 1. A method for preparing a hydrophobic multi-level porous solid acid-base bifunctional catalyst, characterized in that it is carried out according to the following steps:

[0047] (1) Synthesis of basic functionalized hydrophobic nanoparticles

[0048] According to the prior art, mix 0.6 mL of glycidyl methacrylate (GMA) and 60 mL of H 2 O was added to a 250ml three-neck flask, filled with nitrogen for ten minutes, then 2.0mL of styrene (St) and 1.0mL of diethylbenzene (DVB) were added into it, then heated to 90°C, and 0.08g Potassium persulfate was stirred at 600~800rpm for 1-1.5 hours, and after high-speed centrifugation, it was dried in a vacuum oven at 40~50°C for 20~24 hours to obtain hydrophobic styrene epoxy particles (ie: S-GMA); Prepared 0.5g of hydrophobic styrene epoxy particles and 10mL of NH with a concentration ratio of 22% to 25%. 3 ·H 2 O mixing, stirring at 90°C for 9-10 hours under reflux condensation, high-speed centrifugation, and drying in a vac...

Embodiment 3

[0056] 1. A method for preparing a hydrophobic multi-level porous solid acid-base bifunctional catalyst, characterized in that it is carried out according to the following steps:

[0057] (1) Synthesis of basic functionalized hydrophobic nanoparticles

[0058] Mix 0.55 mL of glycidyl methacrylate (GMA) and 58 mL of H 2 O was added to a 250ml three-neck flask, filled with nitrogen for ten minutes, then 1.9mL of styrene (St) and 0.9mL of diethylbenzene (DVB) were added into it, then heated to 90°C, and 0.07g Potassium persulfate was stirred at 600~800rpm for 1-1.5 hours, and after high-speed centrifugation, it was dried in a vacuum oven at 40~50°C for 20~24 hours to obtain hydrophobic styrene epoxy particles (ie: S-GMA); Prepared 0.45g of hydrophobic styrene epoxy particles and 9.5mL of 22%~25% NH 3 ·H 2 O mixing, stirring at 90°C for 9-10 hours under reflux condensation, high-speed centrifugation, and drying in a vacuum oven at 40-50°C for 10-12 hours to obtain alkaline func...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com