Monodisperse ZnO micro/nano material, and preparation method and application thereof

A micro-nano, monodisperse technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of restricting widespread use, high energy consumption, low output, etc., and achieve novel mechanism and high energy efficiency. The effect of low consumption and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

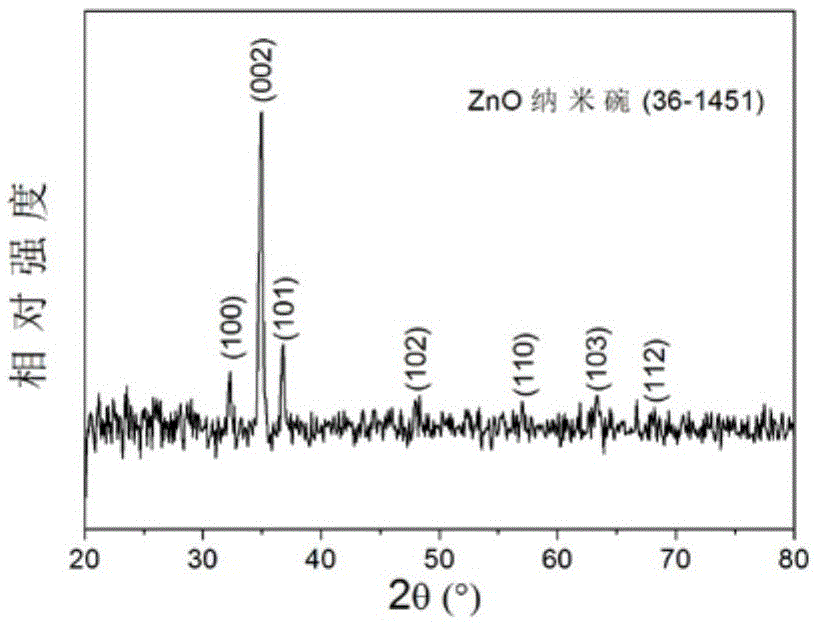

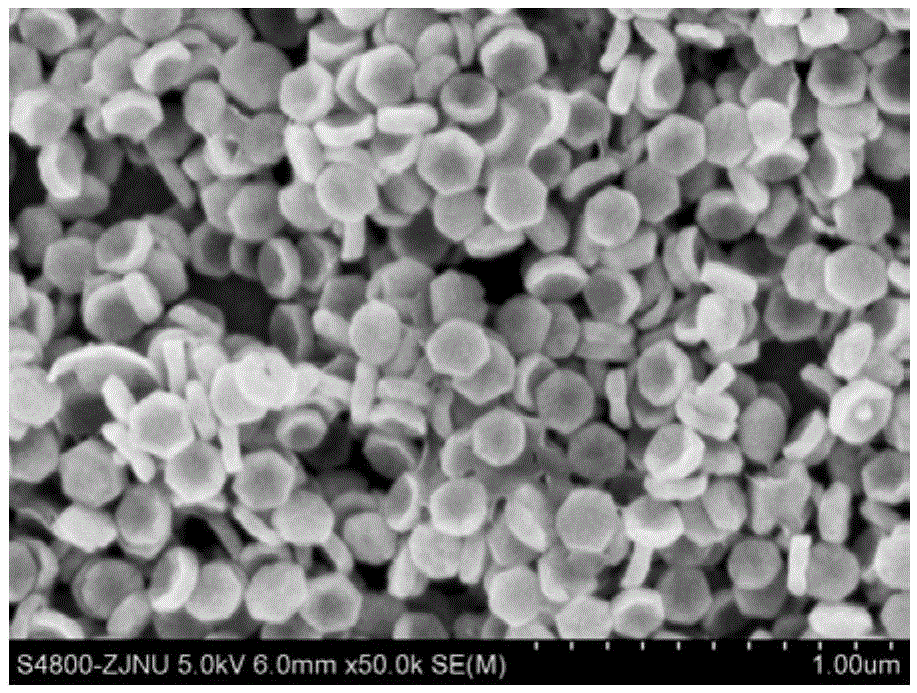

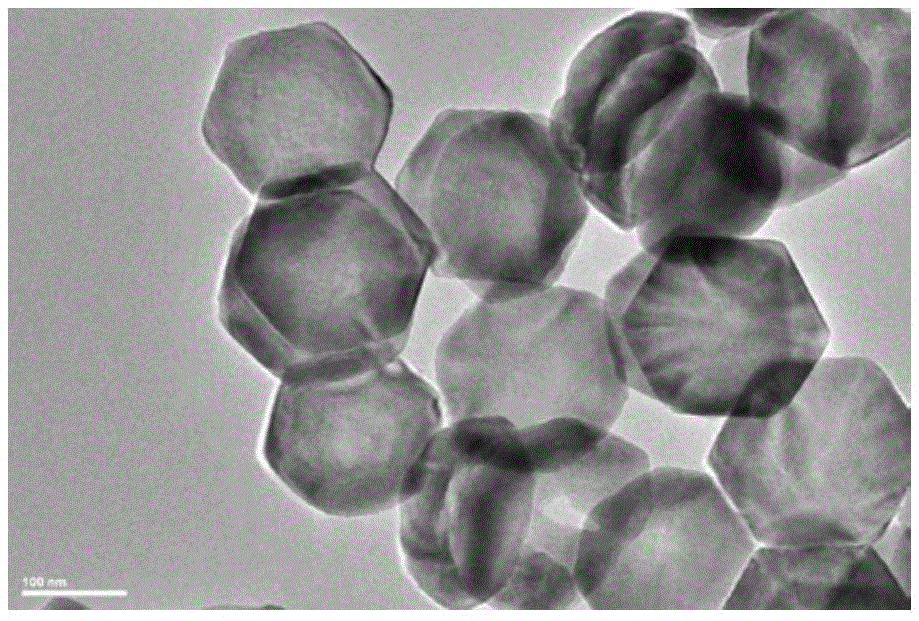

[0037]0.1098 grams of zinc acetate dihydrate, 20.8 milliliters of water and 0.2 grams of CTAB were added to a 400 milliliter beaker and stirred for 15 minutes; then 29.2 milliliters of dimethyl sulfoxide was added and stirred for 30 minutes; then put into an oven at 70 °C for 1.5 hours, then cooled at room temperature for 3 hours, and finally washed and dried with ethanol to obtain the monodisperse ZnO nanobowls. The resulting product is white, and its phase, morphology, structure, selected area electron diffraction pattern, and photocatalytic degradation of Rhodamine B observed under a scanning electron microscope and a transmission electron microscope are as follows: Figure 1-5 As shown, it can be seen that the product is a uniform, monodisperse regular hexagonal ZnO nanobowl with rounded corners, a diameter of 143-205 nm, and a thickness of 39-73 nm.

Embodiment 2

[0039] The steps are the same as in Example 1, but the reaction time is 1 h. The morphology of the obtained product observed under the scanning electron microscope is as follows: Figure 6 As shown, it can be seen that the product is a uniform, monodisperse regular hexagonal ZnO nanobowl with rounded corners, a diameter of 135-190 nm, and a thickness of 42-71 nm. It can be seen that the reaction time is shortened and the size becomes smaller.

Embodiment 3

[0041] The steps are the same as in Example 1, but the reaction time is 1 h, and the cooling time is 0 h (that is, direct centrifugation). The phase of the obtained product, the morphology observed under the scanning electron microscope and the degradation diagram of the photocatalytic degradation of rhodamine B are as follows Figure 7-9 As shown, it can be seen that the product is a uniform, monodisperse regular hexagonal ZnO nanosheet with a diameter of 79-171 nm and a thickness of 37-73 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com