Composite water-treatment coagulant prepared from high-iron gibbsite and preparation method thereof

A high-speed rail trihydrate and coagulant technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem that high-speed rail trihydrate bauxite has not been effectively developed and utilized , energy consumption, large dust and coal pollution, difficult separation of iron and aluminum, etc., to overcome the poor stability of iron salt coagulants, good turbidity removal effect, and small pH change in water treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Aluminum chloride hot metal treatment coagulant

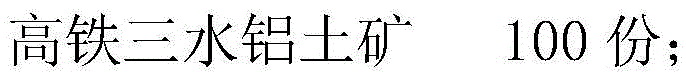

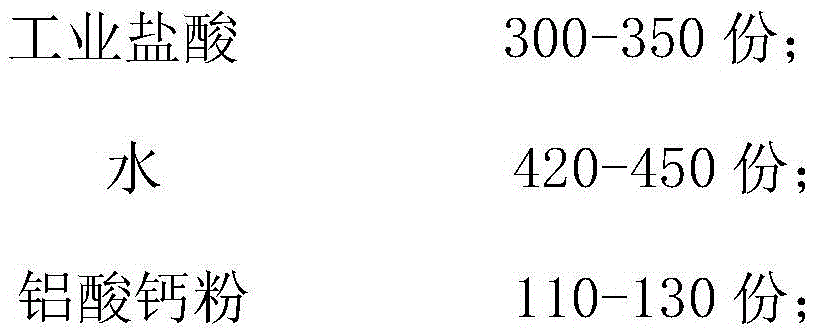

[0040] Described aluminum chloride molten iron treatment coagulant is calculated by weight parts by following component:

[0041] 100 parts of high-speed iron bauxite;

[0042] 350 parts of industrial hydrochloric acid;

[0043] 45 parts of water;

[0044] The preparation of the aluminum chloride hot metal treatment coagulant comprises the following process steps:

[0045] The mined high-iron bauxite is washed with water or screened by a vibrating sieve to separate the laterite to obtain relatively pure high-iron bauxite, and its main component content is controlled: Al 2 o 3 ≥30%, Fe≥10%; grind and crush the above-mentioned high-iron bauxite through a 100-mesh sieve for later use, and take 100 parts of high-iron bauxite powder as the calculation basis, and first go to the normal room with a stirring and heating device Add 45 parts of water to the pressure reaction tank, then add 350 parts of industrial h...

Embodiment 2

[0046] Embodiment 2 Aluminum chloride hot metal treatment coagulant

[0047] Described aluminum chloride molten iron treatment coagulant is calculated by weight parts by following component:

[0048] 100 parts of high-speed iron bauxite;

[0049] 330 parts of industrial hydrochloric acid;

[0050] 50 parts of water;

[0051] The preparation of the aluminum chloride hot metal treatment coagulant comprises the following process steps:

[0052] The mined high-iron bauxite is washed with water or screened by a vibrating sieve to separate the laterite to obtain relatively pure high-iron bauxite, and its main component content is controlled: Al 2 o 3 ≥30%, Fe≥10%; grind and crush the above-mentioned high-iron bauxite through an 80-mesh sieve for later use; take the reaction of 100 parts of high-iron bauxite powder as the calculation basis, and first go to the normal room with a stirring and heating device Add 50 parts of water into the pressure reaction tank, then add 330 parts...

Embodiment 3

[0053] Embodiment 3 Aluminum chloride hot metal treatment coagulant

[0054] Described aluminum chloride molten iron treatment coagulant is calculated by weight parts by following component:

[0055] 100 parts of high-speed iron bauxite;

[0056] 340 parts of industrial hydrochloric acid;

[0057] 47 parts of water;

[0058] The preparation of the aluminum chloride hot metal treatment coagulant comprises the following process steps:

[0059] The mined high-iron bauxite is washed with water or screened by a vibrating sieve to separate the laterite to obtain relatively pure high-iron bauxite, and its main component content is controlled: Al 2 o 3 ≥30%, Fe≥10%; grind and crush the above-mentioned high-iron bauxite through a 120-mesh sieve for later use; take the reaction of 100 parts of high-iron bauxite powder as the accounting basis, and first go to the normal room with a stirring and heating device Add 47 parts of water into the pressure reaction tank, then add 340 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com