Engine coolant and preparation method thereof

A technology of engine coolant and sodium formate, which is applied in the field of engine coolant, can solve the problem of unsatisfactory comprehensive performance of coolant products, and achieve the effect of high anti-fouling and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

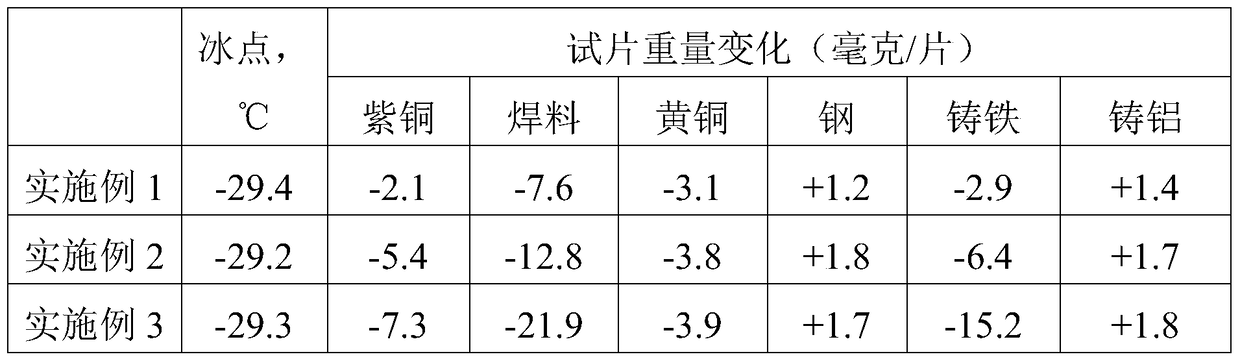

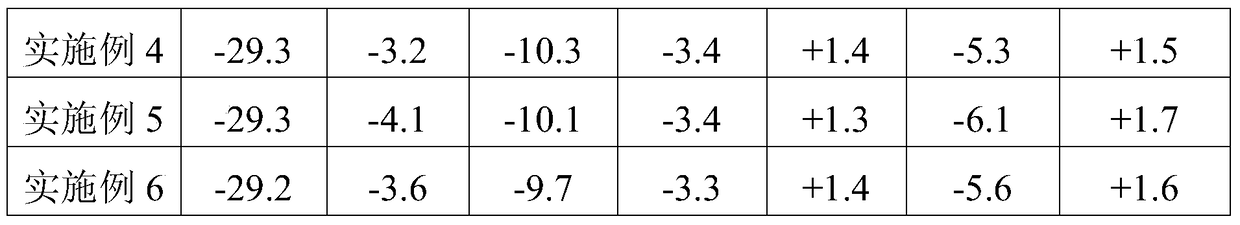

Examples

Embodiment 1

[0041] Engine coolant raw materials: water 6000g, sodium formate 500g, borax 100g, potassium molybdate 6g, suberic acid 10g, sodium caprate 50g, sodium nitrate 10g, benzotriazole 10g, sodium hydroxide 20g, sodium metasilicate nonahydrate 20g , 1,2-propanediol 3000g, glycerol 700g, fluorescein sodium 0.03g, simethicone 0.2g, lanthanum chloride 1g, chelating agent 1g, silicate stabilizer 3g.

[0042] The chelating agent is obtained by stirring and mixing 0.5g ethylenediaminetetraacetic acid and 0.5g diethylenetriaminepentaacetic acid.

[0043] The silicate stabilizer is obtained by uniformly stirring and mixing 1 g of mannitol, 1 g of sorbitol, and 1 g of xylitol.

[0044] The preparation method of engine coolant comprises the following steps:

[0045] (1) Add 500g sodium formate, 100g borax, 6g potassium molybdate, 10g suberic acid, 50g sodium caprate, 10g sodium nitrate, 10g benzotriazole, 20g sodium hydroxide into 5000g water, stir to dissolve, then add 3g silicic acid The ...

Embodiment 2

[0049] It is basically the same as Example 1, except that the chelating agent is only 1 g of ethylenediaminetetraacetic acid. Obtain the engine coolant of embodiment 2.

Embodiment 3

[0051] It is basically the same as Example 1, except that the chelating agent is only 1 g of diethylenetriaminepentaacetic acid. Obtain the engine coolant of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com