Polypeptide for preparing hydrogel and hydrogel made from polypeptide

A technology of hydrogel and buffer solution, which is applied in the field of polypeptide and its prepared hydrogel, which can solve the problems of difficult cell regulation, wide application of chemical residue restrictions, and limited gel strength, so as to avoid potential toxicity and immunogenicity. Sexual Risk Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the present embodiment hydrogel comprises the following steps:

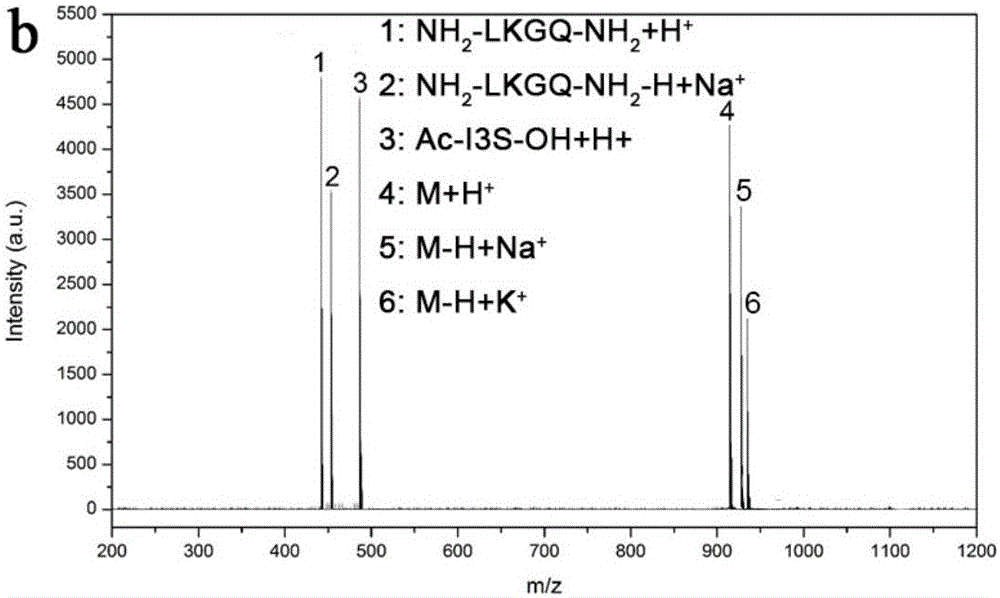

[0043] Peptide Ac-I 3 SLKGQ-NH 2 Under the action of the buffer solution Hepes buffer solution, dilute to a concentration of 8mM, vortex and sonicate, heat in a water bath at 85°C and cool to room temperature, add transglutaminase (TGase) to make the final concentration of TGase The concentration was 0.9U / mL, and incubated at 37°C. After 24 hours and 15 days, hydrogels were able to form. Rheologically tested, such as Figure 4 As shown, Ac-I 3 SLKGQ-NH 2 The storage modulus G' of the polypeptide hydrogel is about 800 Pa, and the loss modulus G" is about 1 / 10 of the storage modulus G', indicating that the system forms a typical hydrogel.

[0044] Hydrogel degradation test: at 37°C, matrix metalloproteinase II (MMP-2) was added to the self-assembled hydrogel to make the final concentration 100ng / mL, and the gel was placed in a 37°C water bath After incubation for 15 days, the...

Embodiment 2

[0046] Ac-I 3 SLKGQ-NH 2 Gel preparation method:

[0047] Select the short peptide Ac-I prepared by the aforementioned solid-phase synthesis method 3 SLKGQ-NH 2Under the action of Hepes buffer, dilute to a concentration of 8mM, after oscillating and sonicating, heat in a water bath at 85°C for 2 hours, cool naturally to room temperature, add 5mM CaCl dissolved in Hepes buffer 2 and 2mM dithiothreitol (DTT) transglutaminase, so that the final concentration of the enzyme is 0.9U / mL, and the final concentration of the short peptide is 7.27mM. The resulting solution was incubated in a water bath at 37°C for 24 hours to obtain an inverted self-supporting hydrogel.

[0048] The gel in embodiment 2 is assayed:

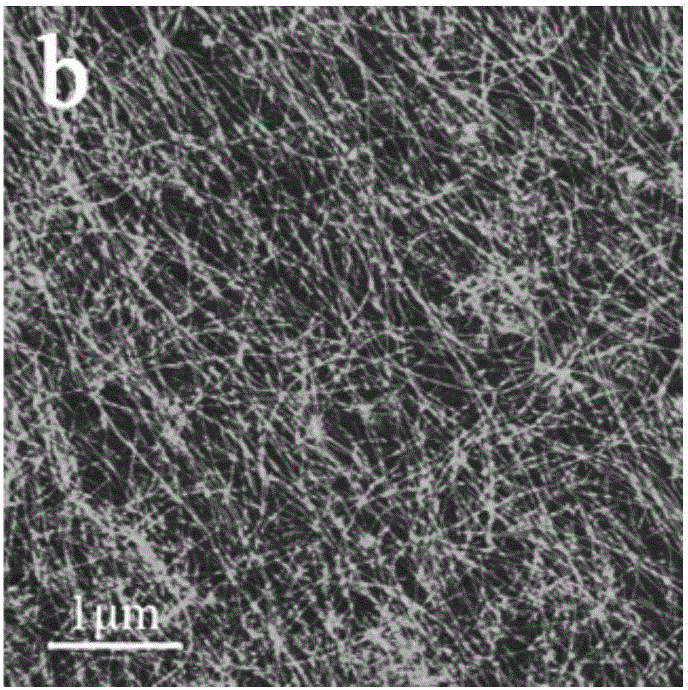

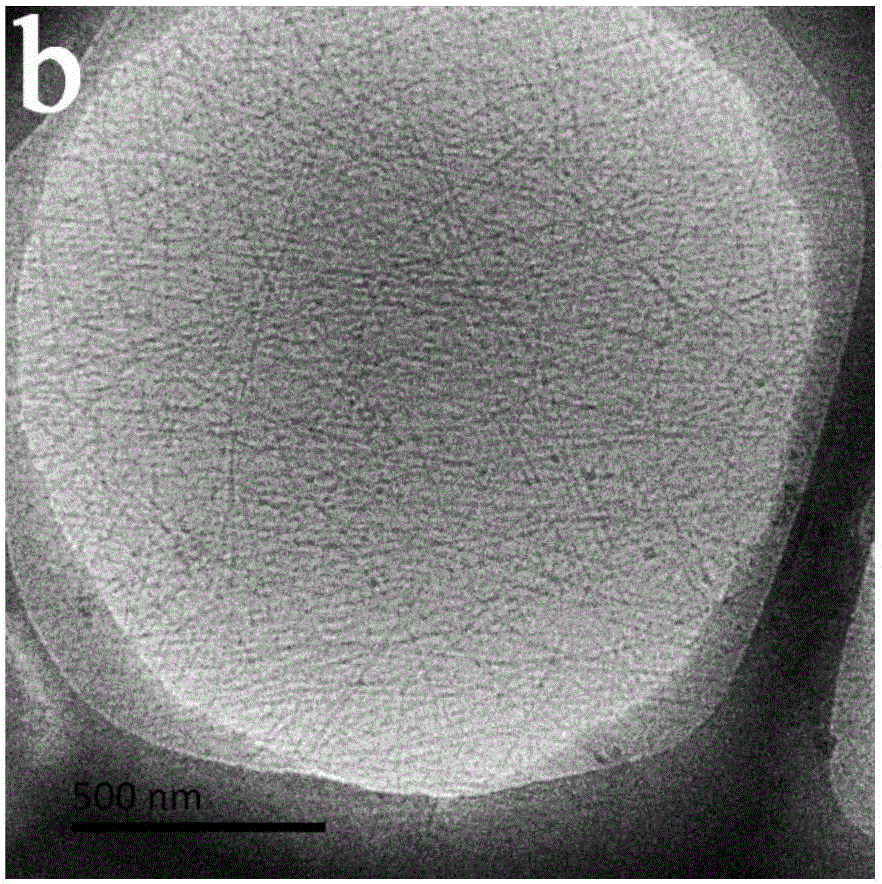

[0049] Pipette 20 μL of Ac-I 3 SLKGQ-NH 2 The gel was added dropwise on the cleaned silicon wafer, and then 300 μL of ultrapure water was added quickly, and after standing for 10 seconds for adsorption, the sample was blown dry with nitrogen gas, and scanned by AFM. It...

Embodiment 3

[0052] Characterization of Ac-I by Haake rheometer 3 SLKGQ-NH 2 For the mechanical properties (viscoelasticity) of hydrogel samples, a cone-plate with a diameter of 35mm and a taper of 2° was used as the rotor, and a flat plate with a diameter of 35mm was used as the stator. The sample volume used for each measurement was 400 μL, and the experimental temperature was constant at 25°C. Stress scanning is carried out at a frequency of 1Hz, and the scanning range is from 0.01% to 100%. The linear viscoelastic region of the gel is measured, and the appropriate stress is selected from the linear viscoelastic region for dynamic frequency scanning, and the scanning range is from 0.01Hz to 100Hz. The relationship between the energy modulus G' and the energy loss modulus G".

[0053] Ac-I 3 SLKGQ-NH 2 Dilute to a concentration of 8mM under the action of Hepes buffer, add transglutaminase according to the method of Example 2, and place it in a water bath at 37°C for 24 hours, then tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com