A kind of high-efficiency luminescent microsphere and its preparation method and application

A high-efficiency technology of luminescent microspheres, applied in the field of indication, high-efficiency luminescent microspheres, signs, high-efficiency luminescent microspheres in the field of lighting, can solve the problems of low luminous intensity and poor luminous effect, and achieve low raw material requirements, Increased brightness and improved luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

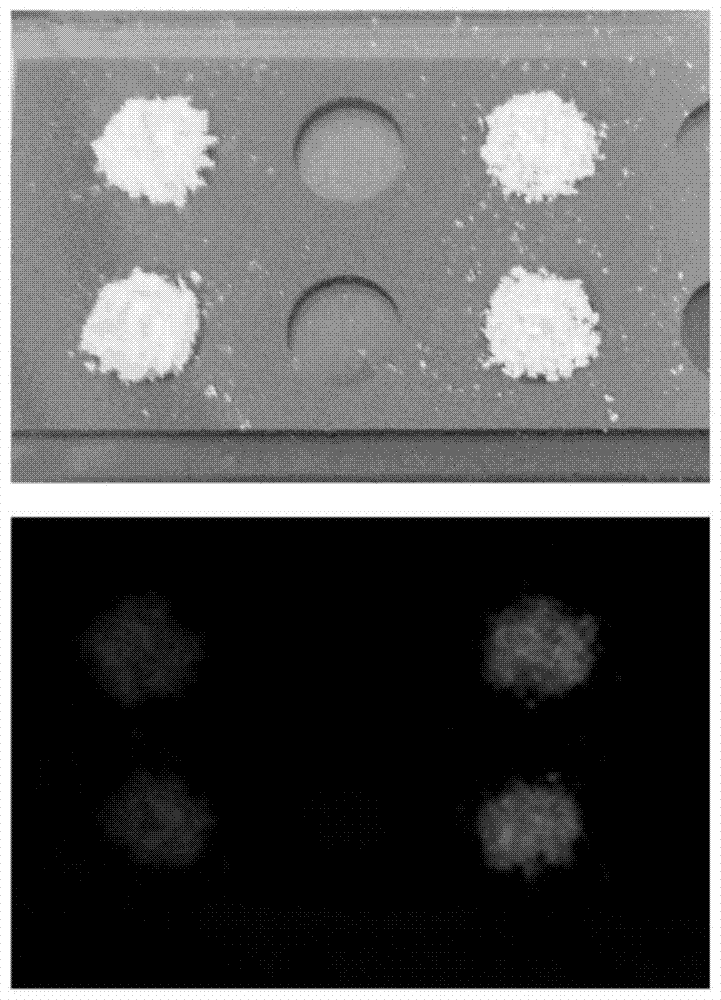

Image

Examples

Embodiment 1

[0022] MgO·Al 2 o 3 0.4SiO2 2 : Light-storing phosphor powder (SP-6) of Eu component and polyvinylpyrrolidone are mixed evenly in a mass ratio of 3:1 (mass ratio can be 5:1~1:1), and then fully stirred in deionized water to make It dissolves well in the aqueous phase. The resulting dispersion was then charged into the container of the spray drying apparatus, and the inlet temperature of the spray drying apparatus was adjusted to 200°C. The carrier gas (air) used by the spray drying equipment carries the dispersion liquid for spray drying. The particle diameter of described microsphere can be by the content of the solid (storage type fluorescent powder and polyvinylpyrrolidone) contained in the regulation and control dispersion liquid, the volume of dispersion liquid and the parameter of spray drying (as the sampling speed of dispersion liquid, The inlet temperature of the spray drying instrument and the injection speed of the carrier gas (air)) are regulated. High-efficie...

Embodiment 2

[0024] The small molecular dye rhodamine 6G was dissolved in deionized water to form a solution with a mass fraction of 0.02%. Then polyacrylic acid (number average molecular weight: 3000) was added to the solution, so that the mass fraction of the obtained polyacrylic acid (number average molecular weight: 3000) was 8%. The high molecular polymer has the functions of regulating surface tension and viscosity at the same time. After fully shaking and sonicating until the polyacrylic acid was completely dissolved, the solution was used as ink for inkjet printing. Ink-jet printing was carried out with a printer on a 3 mm thick and cleaned polytetrafluoroethylene sheet with the ink prepared above. A nozzle of 10 picoliters was selected to keep the distance between the droplets at 100 microns, so that the droplets would not merge with each other after contacting the PTFE sheet, and as many droplets as possible could be prepared on the PTFE sheet. After printing, the PTFE sheet wa...

Embodiment 3

[0026] Dissolve 10 milliliters of tetrabutyl titanate in 16 milliliters of absolute ethanol to obtain mixed solution 1; add 1 milliliter of 2.35 moles per liter of concentrated nitric acid to 32 milliliters of absolute ethanol, oscillate fully to mix evenly, and obtain a mixed solution 2. Under magnetic stirring, slowly drop 15 ml of mixed solution 2 into 20 ml of mixed solution 1, and continue to stir for 8-12 hours. After the stirring is completed, a uniform and transparent sol is obtained. Add 2 grams of phosphor powder with the composition of Sr2SiO3:Dy3+ therein, and then let it stand for 24-36 hours to slowly aggregate between the colloidal particles. This process is the aging process of the colloidal particles. After standing, a gel with a three-dimensional network structure is obtained. Dry the obtained gel in an oven at 50 degrees Celsius for 8 hours to remove residual moisture and organic solvents to obtain a xerogel. The obtained dry gel is calcined at 450 degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com