Direct smelting method and system for producing metallic lead and zinc at the same time

A smelting method and metal lead technology, applied in the field of direct smelting methods and systems that simultaneously produce metal lead and zinc, can solve the problems of numerous equipment, dust pollution, low concentration, etc., and achieve environmental protection, production cost reduction, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

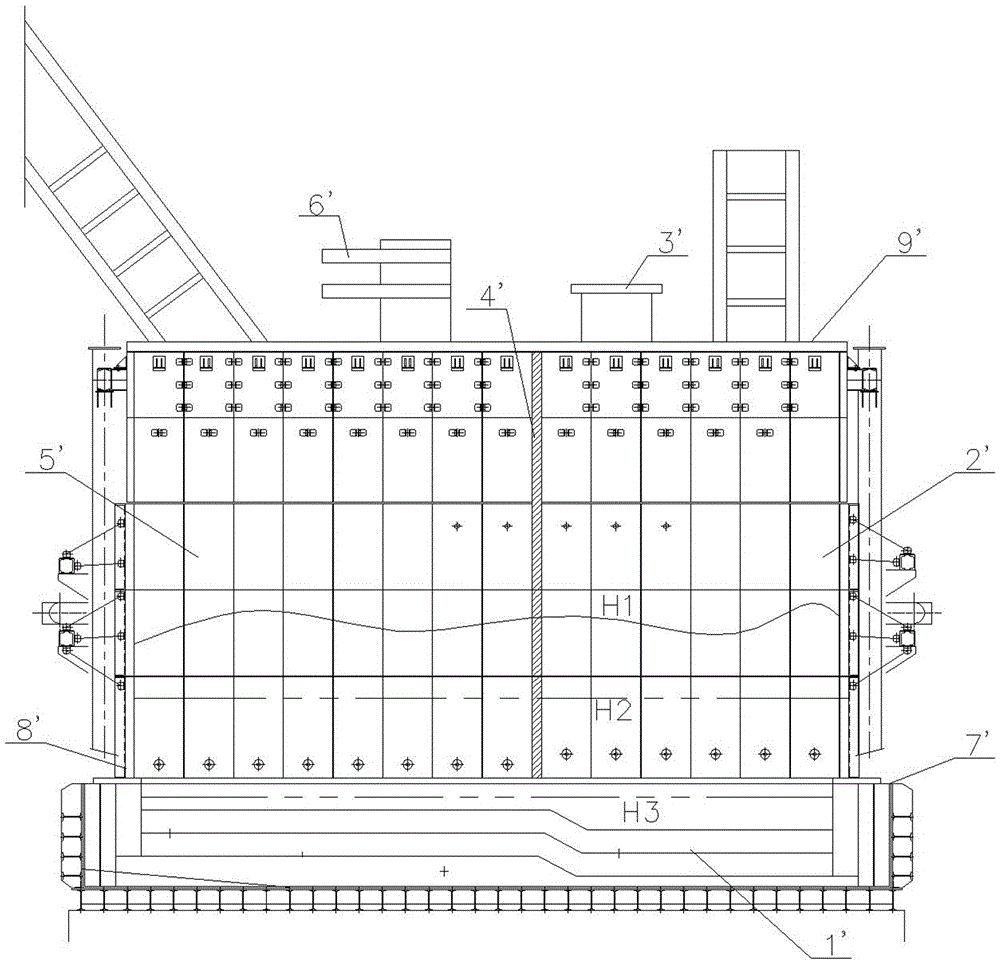

[0034] Such as figure 1 As shown, the dual-zone oxygen-enriched side-blowing furnace adopted in the present invention has a rectangular fixed body of furnace, consisting of hearth 1 ', furnace body, furnace top 9 ' and straight-up flue. The furnace hearth 1' is made of refractory materials, and the molten pool part is covered with a steel plate shell. The lower part of the furnace body is equipped with 2 to 3 layers of copper water jackets, and the upper part of the furnace body and the vertical flue are "sandwich" walls made of steel water jackets or copper water jackets and refractory bricks. Furnace roof 9' is a molten steel jacket.

[0035] The partition wall 4' formed by the copper water jacket divides the furnace body of the oxygen-enriched side-blown furnace into two areas along the length direction, which are respectively called the smelting area 2' and the fuming area 5', and the hearth 1' is connected to each other. The top of the smelting zone 2' is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com