Preparation method of polyacrylonitrile precursor

A technology of polyacrylonitrile and acrylonitrile, which is applied in the field of preparation of polyacrylonitrile precursors, can solve the problems of low strength and unstable performance of carbon fiber precursors, and achieve the effects of high density, guaranteed stability and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

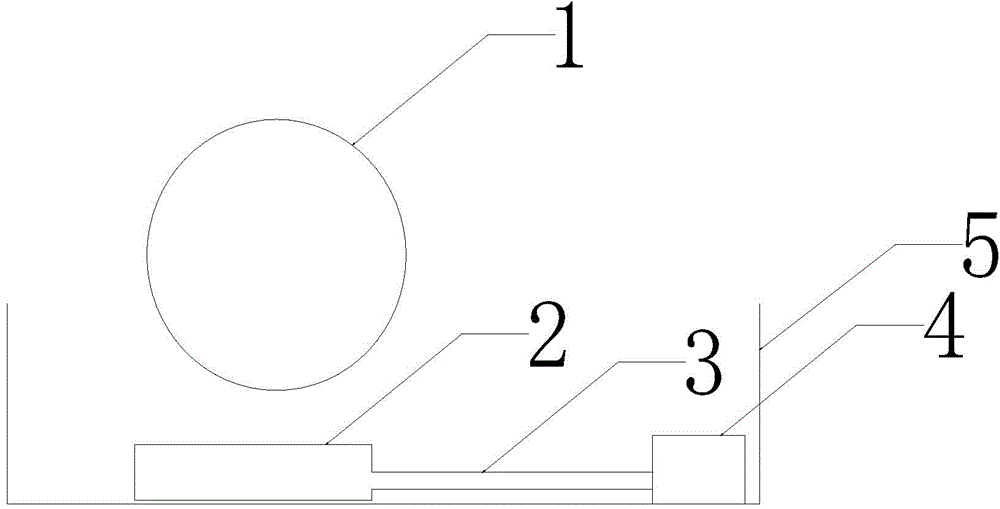

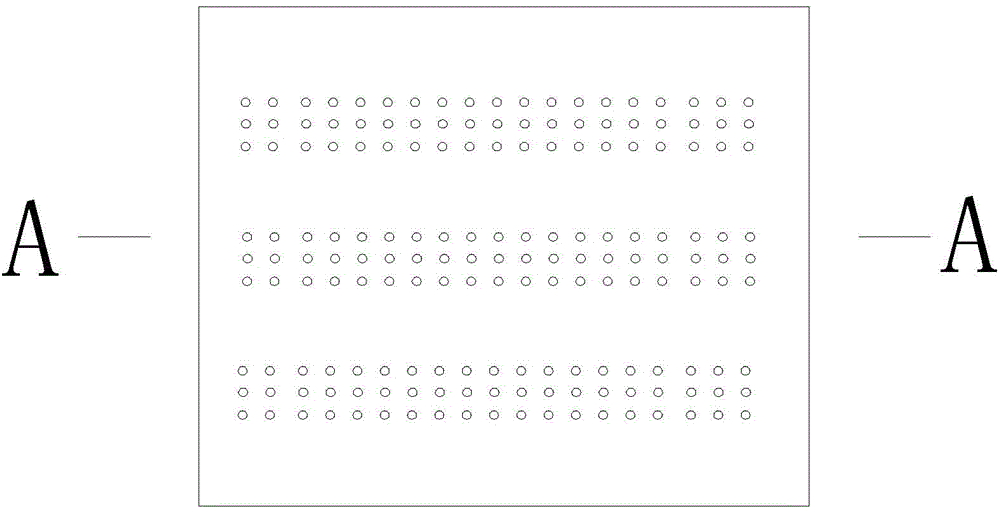

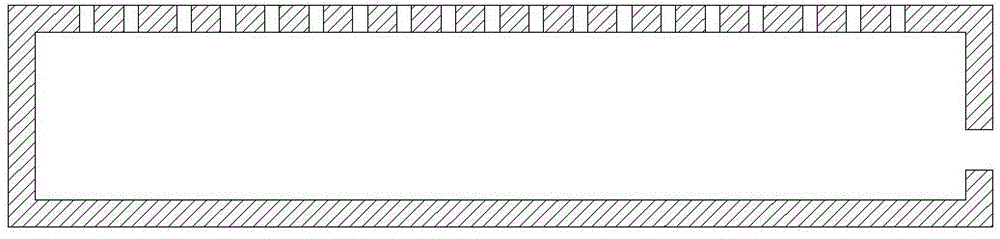

Image

Examples

Embodiment 1

[0024] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain a high-performance polyacrylonitrile copolymer spinning solution.

[0025] 2. Coagulation molding: Extrude through the spinneret and enter the first coagulation bath, the temperature of the coagulation bath is 20°C, the concentration is 50%, the draft ratio is -30%, the second coagulation bath is 40°C, the concentration is 40% %, the draft ratio is 100%, the third coagulation bath is 60°C, the concentration is 3...

Embodiment 2

[0033] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain a high-performance polyacrylonitrile copolymer spinning solution.

[0034] 2. Coagulation molding: Extrude through the spinneret and enter the first coagulation bath, the temperature of the coagulation bath is 20°C, the concentration is 50%, the draft ratio is -30%, the second coagulation bath is 40°C, the concentration is 40% %, the draft ratio is 100%, the third coagulation bath is 60°C, the concentration is 3...

Embodiment 3

[0040] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material to obtain a high-performance polyacrylonitrile copolymer spinning solution.

[0041] 2. Coagulation molding: Extrude through the spinneret and enter the first coagulation bath, the temperature of the coagulation bath is 20°C, the concentration is 50%, the draft ratio is -30%, the second coagulation bath is 40°C, the concentration is 40% %, the draft ratio is 100%, the third coagulation bath is 60°C, the concentration is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com