Tiopronin concentration determination fluorescence sensor and preparation method thereof

A fluorescence sensor, tiopronin technology, applied in fluorescence/phosphorescence, instruments, measuring devices, etc., can solve the problem of weak research on thin-film fluorescence sensors, achieve regeneration and reuse, convenient and fast detection process, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

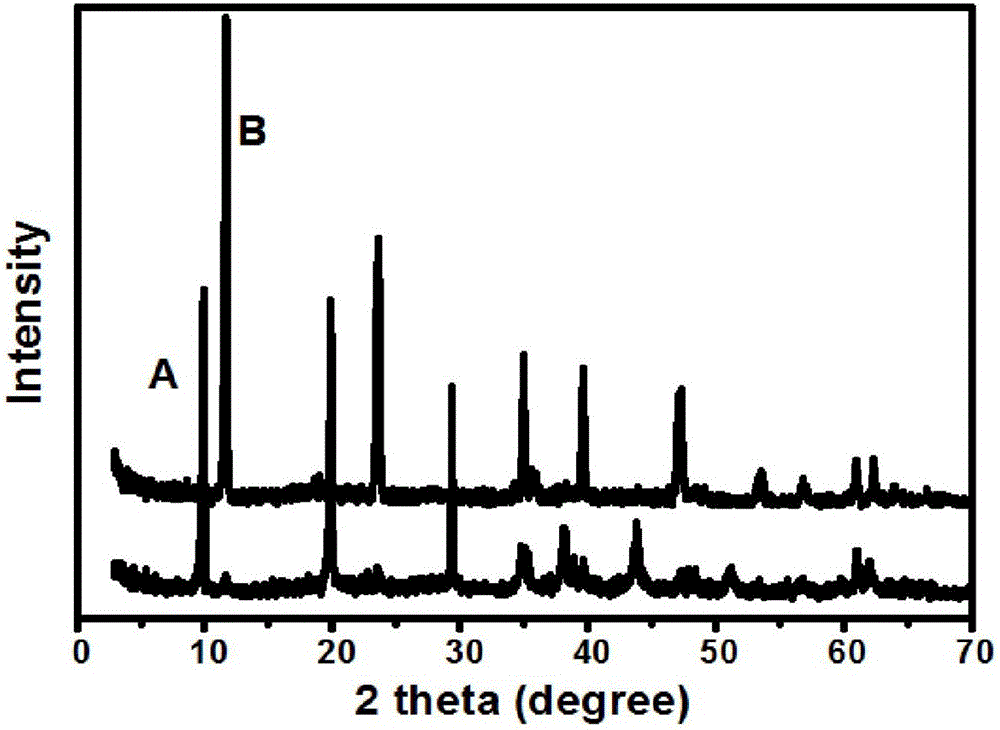

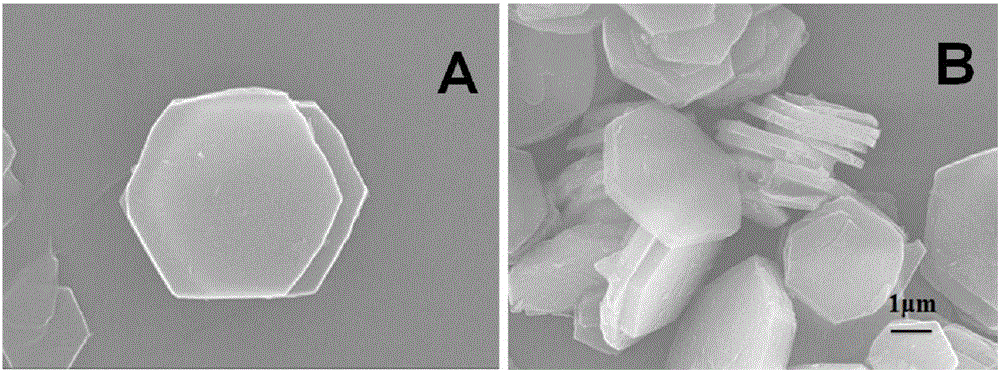

[0034] 1. Preparation of hydrotalcite precursor: 0.002mol solid Mg(NO 3 ) 2 ·6H 2 O, 0.01mol solid Al(NO 3 ) 3 9H 2 O and 0.012mol urea were dissolved in 70ml of deionized water, reacted at 100°C for 24 hours in a 90ml polytetrafluoroethylene-lined pressure reaction vessel, and were centrifugally washed with deionized water until the pH was about 7, 60 Dry in the air under the condition of ℃ to obtain the hydrotalcite microcrystalline Mg intercalated with carbonate-type anions 0.67 Al 0.33 (OH) 2 (CO 3 ) 0.33 2H 2 O. Get the hydrotalcite crystallite 0.3g of above-mentioned carbonate type anion intercalation and solid NaNO 3 63.75g dissolved in 300mL to remove CO 2 After being uniformly dispersed in deionized water, add 0.08mL concentrated nitric acid and stir at 25°C under a nitrogen atmosphere to carry out ion exchange reaction for 24 hours and then use 2 The deionized hot water was centrifuged and washed to a pH of about 7, and dried at 60°C for 12 hours to obta...

Embodiment 2

[0053] 1. Same as implementation case 1;

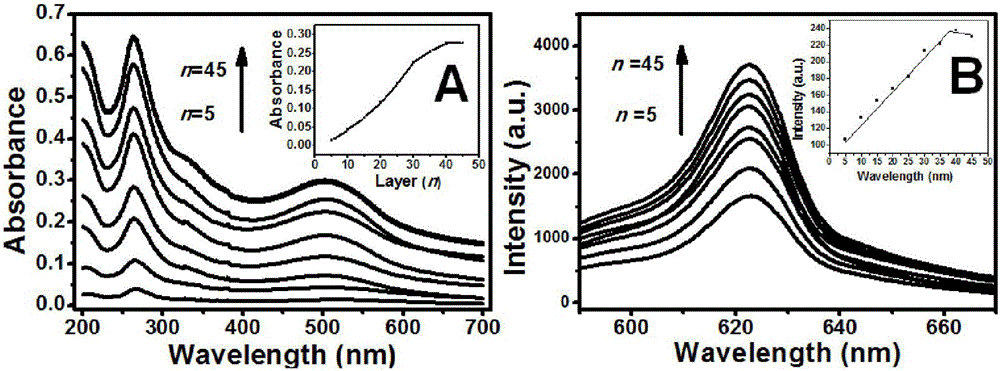

[0054] 2. Take 0.11 g of the above-mentioned nitrate intercalated hydrotalcite, and stir it in 110 mL of formamide solvent for 47 hours under a nitrogen atmosphere at a stirring speed of 2500 rpm, centrifuge the stripped hydrotalcite solution, discard the precipitate, Obtain clear transparent hydrotalcite laminate colloidal solution;

[0055] 3. The preparation concentration is 10 -3 mol / L alizarin red and boric acid mixed solution with a concentration of 0.15mol / L, after adjusting the pH value to 6.5 with NaOH, store it in a volumetric flask in the dark;

[0056] 4. Take a 3cm×1cm quartz plate and use concentrated H with a volume ratio of 7:3 2 SO 4 and H 2 o 2 Wash it with the mixed solution of ethanol and deionized water alternately for 2 times, each time for 15 minutes, then place it in a 19-fold diluted PDDA solution and soak it for 28 minutes, take it out, rinse it with deionized water and dry it at room temperature ; This...

Embodiment 3

[0060] 1. Same as implementation case 1;

[0061] 2. Take 0.15 g of the above-mentioned nitrate intercalated hydrotalcite, and stir it in 150 mL of formamide solvent for 46 hours under a nitrogen atmosphere, at a stirring speed of 2600 rpm, centrifuge the stripped hydrotalcite solution, discard the precipitate, A clear and transparent colloidal solution was obtained.

[0062] 3. The preparation concentration is 10 -3 mol / L alizarin red and boric acid mixed solution with a concentration of 0.25mol / L, after adjusting the pH value to 7.5 with NaOH, store it in a volumetric flask in the dark;

[0063] 4. Take a 3cm×1cm quartz plate and use concentrated H with a volume ratio of 7:3 2 SO 4 and H 2 o 2 Wash it with the mixed solution of ethanol and deionized water alternately for 18 minutes each time, then place it in a diluted 21-fold volume of PDDA solution for 25 minutes, take it out, rinse it with deionized water and dry it at room temperature ; This process is a pre-assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com