Dual-function catalyst for hydrogenating benzene rings and reducing carbonyl, preparation of dual-function catalyst and application thereof

A bifunctional catalyst and catalyst technology, which can be used in the preparation of hydroxyl compounds, hydrogenation to hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

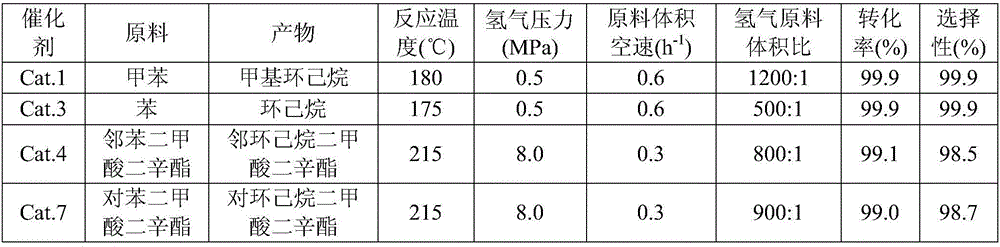

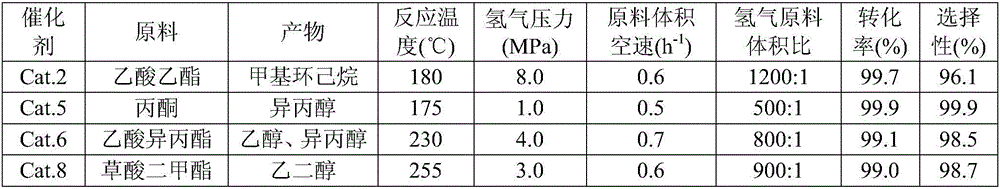

Examples

Embodiment 1

[0041] 75.9gCu(NO 3 ) 2 ·3H 2 O, 105.5gNiSO 4 ·6H 2 O is added in distilled water, and sodium carbonate solution is added dropwise under stirring and heating conditions to form a slurry precipitate until the pH value is between 5-9, suction filtration, washing filter cake, filter cake is added to deionized water for beating, to obtain Mass fraction is 15% slurry, in slurry, add 45g as the SiO of catalyst carrier 2 , impregnated at 80°C for 4 hours to obtain an impregnating solution; dried the impregnating solution at 120°C for 6 hours; roasted the dried powder at a temperature of 550°C for 5 hours, and compressed the calcined powder into granules, namely It can be obtained from the main catalytic components CuO and NiO and the carrier SiO 2 composed of bifunctional catalysts.

Embodiment 2

[0043] 75.9gCu(NO 3 ) 2 ·3H 2 O, 116.8gNi(NO 3 ) 2 ·6H 2 O is added in distilled water, and sodium carbonate solution is added dropwise under stirring and heating conditions to form a slurry precipitate until the pH value is between 5-9, suction filtration, washing filter cake, filter cake is added to deionized water for beating, to obtain Mass fraction is 15% slurry, in slurry, add 44.5g as the SiO of catalyst carrier 2 and 1.8g of Zn(NO 3 ) 2 ·6H 2 O, soaking at 80°C for 4 hours to obtain an impregnating solution; drying the impregnating solution at 120°C for 6 hours; calcining the dried powder at a temperature of 550°C for a calcining time of 5 hours, and tableting and granulating the calcined powder, It can be obtained from the main catalytic components CuO and NiO, the promoter component ZnO and the carrier SiO 2 composed of bifunctional catalysts.

Embodiment 3

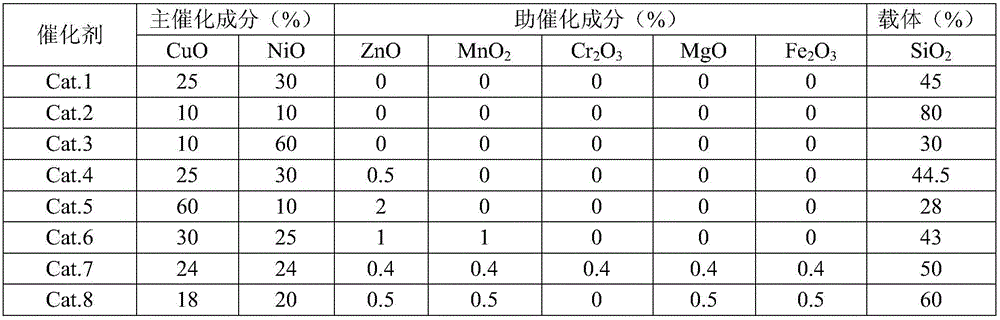

[0045] According to the method of embodiment 1 or 2, change the charging amount and use different metal salts to obtain a series of bifunctional catalysts with different components and contents, and its components and contents are shown in the following table 1:

[0046] In the process of catalyst preparation, each parameter can be adjusted within a certain range. The concentration of the slurry can be 5-20% during beating, the temperature during impregnation is 75-85°C, the impregnation time is 1-6h, and the drying of the impregnation solution is Dry at 100-150°C for 1-6h; the temperature of the dried powder is calcined at 200-650°C, and the calcining time is 1-8°C. When beating, the slurry concentration is preferably 10-20%. When impregnating, it is best to impregnate at 75-85°C for 3-5h. The drying of the impregnating solution is to dry at 110-130°C for 5-7h; The temperature is 400-600°C, and the firing time is 4-6°C.

[0047] The main catalytic component and the pro-catalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrier specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com