Preparation method of carbon aerogel for air filtration

A carbon aerogel and air filtration technology, which is applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of air purification without systematic literature reports, etc., and achieves a simple and convenient preparation process, low energy consumption, and improved air The effect of purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

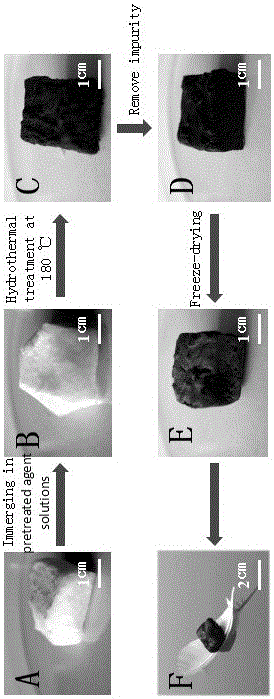

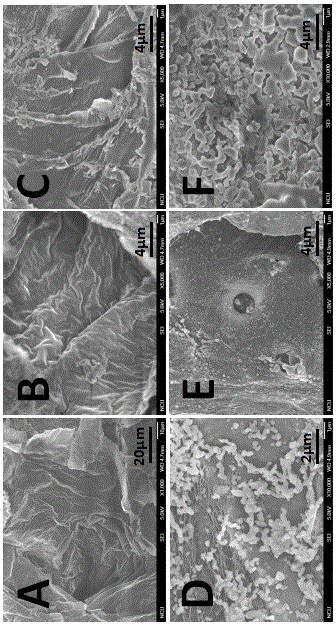

[0026] Preparation of carbon airgel:

[0027] A. Firstly separate the pulp, seeds and the outer skin of the grapefruit, then cut off the yellow skin of the outer skin of the grapefruit to obtain white soft grapefruit peels, and finally cut the white soft grapefruit peels into pieces shape;

[0028] B, soak the sliced pomelo peel in 0.02M ascorbic acid, 0.02M glucose, 0.02M potassium hydroxide, 0.02M potassium chloride and 0.02M ferric chloride solution respectively, soaking for 2 hours each time;

[0029] C. Put the soaked grapefruit peel in a stainless steel autoclave made of polytetrafluoroethylene material for hydrothermal carbonization, that is: put the sealed stainless steel autoclave in a constant temperature drying box, and put the grapefruit peel in water at 60 ° C. Heat for 6 hours, then take it out to get a black carbon hydrogel;

[0030] D. Soak the black carbon hydrogel in absolute ethanol to remove impurities, and take it out after 24 hours;

[0031...

Embodiment 2

[0035] Preparation of carbon airgel:

[0036] A. Firstly separate the pulp, seeds and the outer skin of the grapefruit, then cut off the yellow skin of the outer skin of the grapefruit to obtain white soft grapefruit peels, and finally cut the white soft grapefruit peels into pieces shape;

[0037] B, soak the sliced pomelo peel in 0.4M ascorbic acid, 0.4M glucose, 0.4M potassium hydroxide, 0.4M potassium chloride and 0.4M ferric chloride solution respectively, soaking for 5 hours each time;

[0038] C. Put the soaked pomelo peel in a stainless steel autoclave made of polytetrafluoroethylene material for hydrothermal carbonization, that is: put the sealed stainless steel autoclave in a constant temperature drying box, and put the grapefruit peel in water at 200 ° C. Heat for 12 hours, then take it out to get a black carbon hydrogel;

[0039] D. Soak the black carbon hydrogel in absolute ethanol to remove impurities, and take it out after 48 hours;

[0040] E. ...

Embodiment 3

[0044] Preparation of carbon airgel:

[0045] A. Firstly separate the pulp, seeds and the outer skin of the grapefruit, then cut off the yellow skin of the outer skin of the grapefruit to obtain white soft grapefruit peels, and finally cut the white soft grapefruit peels into pieces shape;

[0046] B, soak the sliced pomelo peel in 2M ascorbic acid, 2M glucose, 2M potassium hydroxide, 2M potassium chloride and 2M ferric chloride solution respectively, soaking for 10 hours each time;

[0047] C. Put the soaked grapefruit peel in a stainless steel autoclave made of polytetrafluoroethylene material for hydrothermal carbonization, that is: put the sealed stainless steel autoclave in a constant temperature drying box, and put the grapefruit peel in water at 120 ° C. Heat for 24 hours, then take it out to get a black carbon hydrogel;

[0048] D. Soak the black carbon hydrogel in absolute ethanol to remove impurities, and take it out after 36 hours;

[0049] E. Soak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com