Efficient slag-based inorganic phosphorous removal flocculating agent and preparation method thereof

A coagulant and slag technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve the problems of environmental pollution, waste of resources, low aluminum leaching rate, etc. Efficient utilization of resources, enhanced adsorption performance, and high phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention provides a high-efficiency slag-based inorganic phosphorus removal coagulant and a preparation method thereof, comprising the following steps:

[0047] 1) Raw material pretreatment: pulverize fly ash and bauxite respectively, grind them, pass through a 100-mesh sieve, and then place them in an oven to dry at 103°C-105°C;

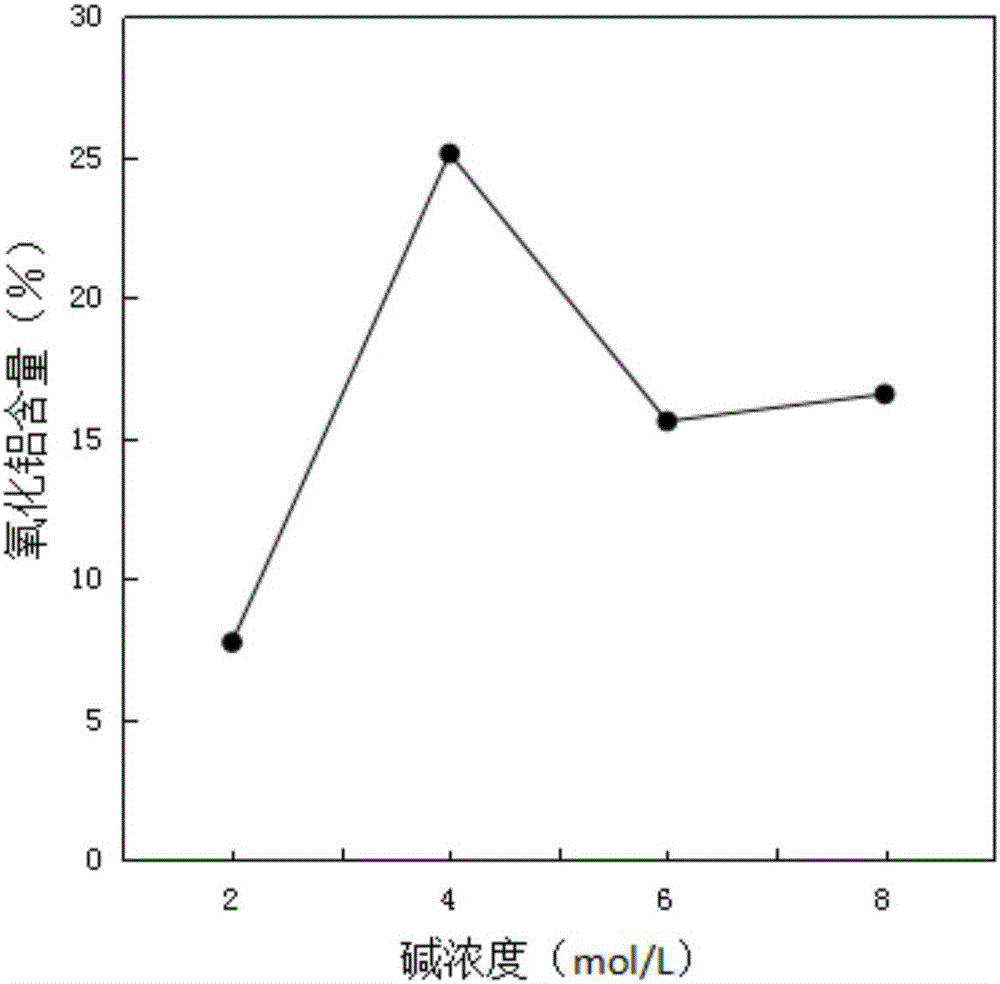

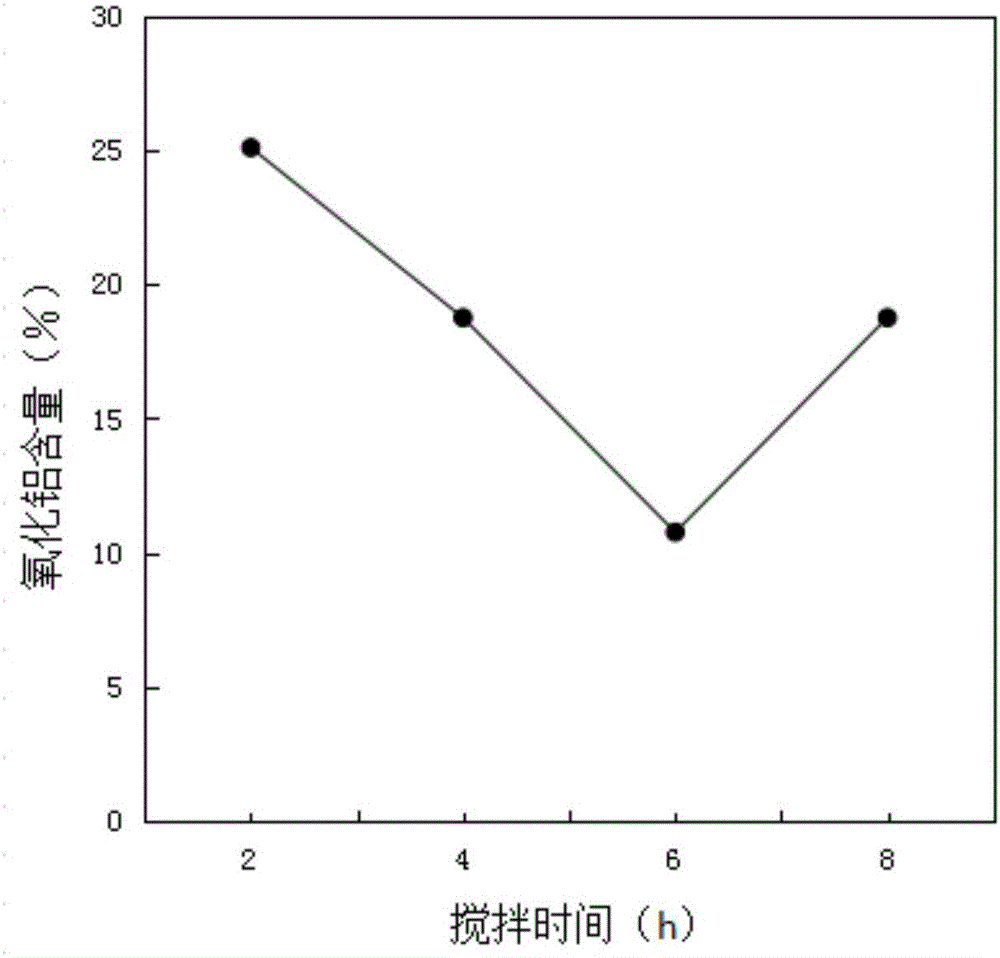

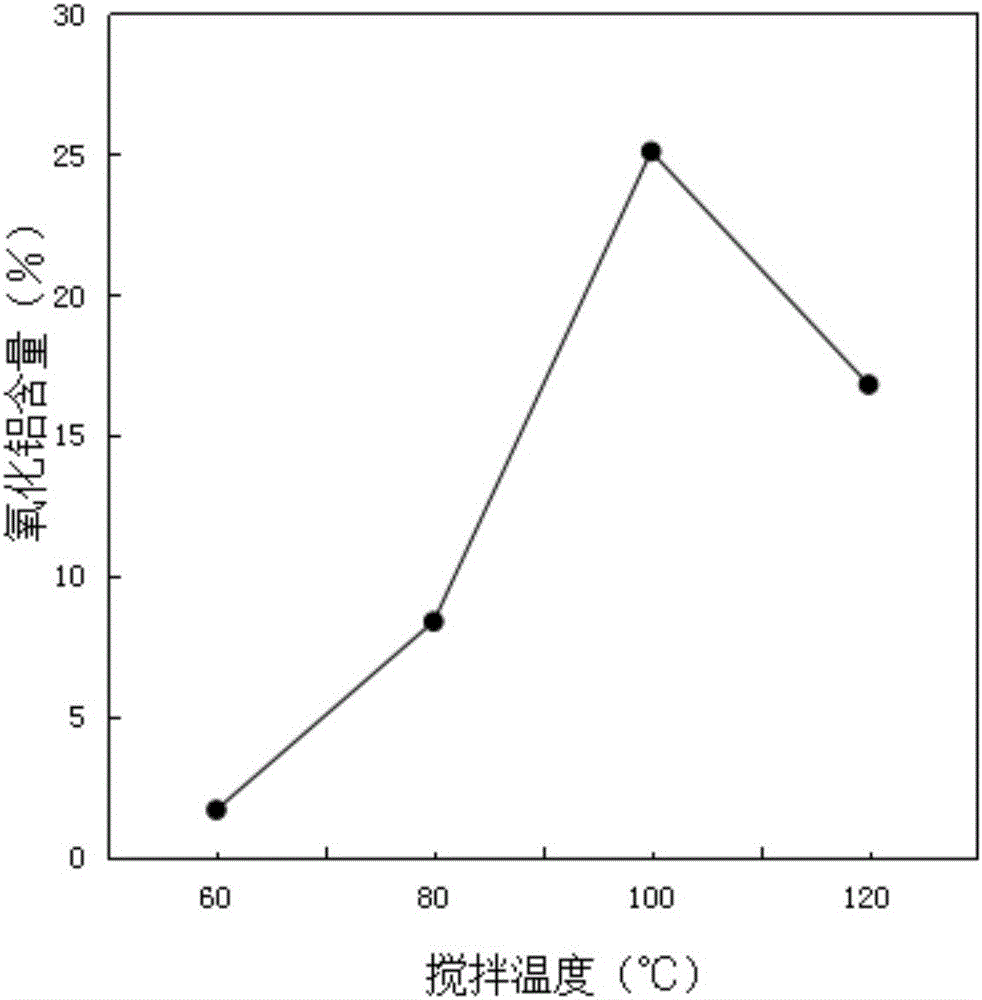

[0048]2) Alkaline leaching extraction: weigh 8g each of the dried fly ash and bauxite, put them in a three-necked flask, and use 160mL NaOH solution with a concentration of 4mol / L for alkali leaching extraction: at 100°C, with Stir for 2 hours on a DC digital display temperature-controlled agitator at a speed of 250r / min, leave to age for 24 hours, and filter with a filter cloth to obtain alkali supernatant A and filter residue A;

[0049] 3) Acid leaching extraction: Rinse the filter residue A three times with distilled water, add 160 mL of hydrochloric acid with a concentration of 2 mol / L to acidify, and stir at 100 ° C for 2 h on a DC...

Embodiment 2

[0053] The present invention provides a high-efficiency slag-based inorganic phosphorus-removing coagulant and a preparation method thereof. The steps are the same as in Example 1, except that in step 4): the volume ratio of alkali supernatant A and acid supernatant B is 1 :16.

Embodiment 3

[0055] The present invention provides a high-efficiency slag-based inorganic phosphorus-removing coagulant and a preparation method thereof. The steps are the same as in Example 1, except that in step 4): the volume ratio of alkali supernatant A and acid supernatant B is 1 :20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com