A kind of antibacterial enhanced water-based paint additive and preparation method thereof

A technology of water-based coatings and additives, applied in the field of its preparation, can solve the problems of large particle size differences of nanomaterials, narrow particle size distribution of nano-zinc oxide, and large concentration of released negative ions, etc., to achieve narrow particle size distribution, good anti-sedimentation performance, and release negative ions The effect of high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An antibacterial enhanced water-based coating additive, which is composed of the following components in mass percentage: 79.44% deionized water, 10% needle-shaped inorganic material whiskers, 10% nano-zinc oxide antibacterial agent, 0.03% water-based dispersant, and water-based coupling agent 0.03%, anti-settling wetting agent 0.5%.

[0034] The pH value of the deionized water is 7.

[0035] The needle-shaped inorganic material whiskers are calcium sulfate whiskers, the diameter before grinding is 3 microns, and the needle length is 30 microns.

[0036] The particle size of the zinc oxide antibacterial agent before grinding is less than 20 microns.

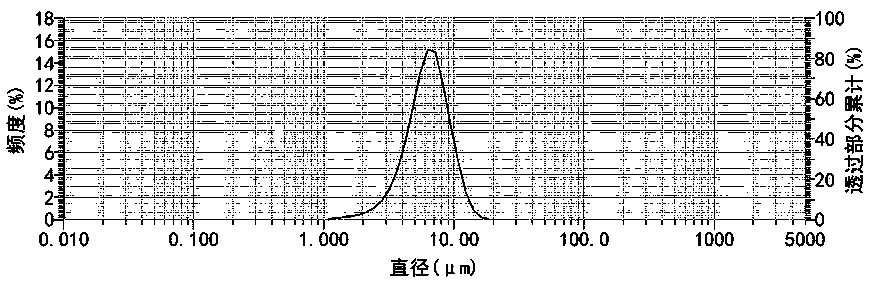

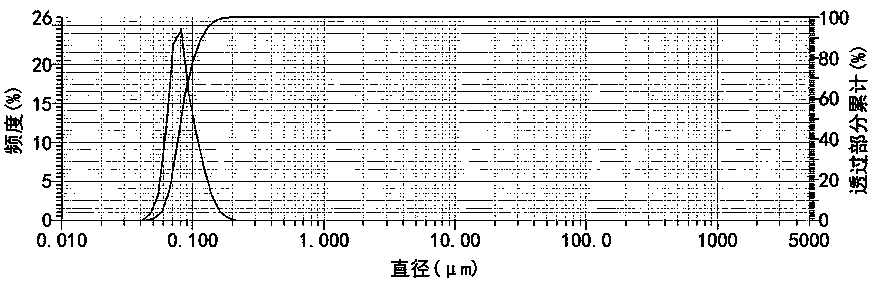

[0037] The micron zinc oxide particle size data table before grinding measured by LA960WET particle size analyzer is shown in the following table:

[0038] (The data in the table shows that the pass rate of particle size 19.9µm is 100%)

[0039]

[0040] The preparation method of described antibacterial enhanced wate...

Embodiment 2

[0051] An antibacterial enhanced water-based coating additive, which is composed of the following components in mass percentage: 79.44% deionized water, 5% needle-shaped inorganic material whiskers, 15% nano-zinc oxide antibacterial agent, 0.03% water-based dispersant, and water-based coupling agent 0.03%, anti-settling wetting agent 0.5%.

[0052] Wherein, the needle-shaped inorganic material whisker is a mixture of calcium sulfate whisker and silicon carbide whisker.

[0053] Other parts of this embodiment are the same as Embodiment 1.

Embodiment 3

[0055] An antibacterial enhanced water-based coating additive, which is composed of the following components in mass percentage: 79.44% deionized water, 15% needle-shaped inorganic material whiskers, 5% nano-zinc oxide antibacterial agent, 0.03% water-based dispersant, and water-based coupling agent 0.03%, anti-settling wetting agent 0.5%.

[0056] Wherein, the needle-shaped inorganic material whisker is a mixture of calcium carbonate whisker, calcium sulfate whisker and silicon carbide whisker.

[0057] Other parts of this embodiment are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com