Blue-light-filtering anti-dazzle wear-resistant touch display screen and manufacturing method thereof

A technology that touches the display screen and filters blue light. It is applied in the input/output process of data processing, ion implantation, plating, coating, etc. It can solve the problems of little sterilization function, infection of bacteria, and impact on aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

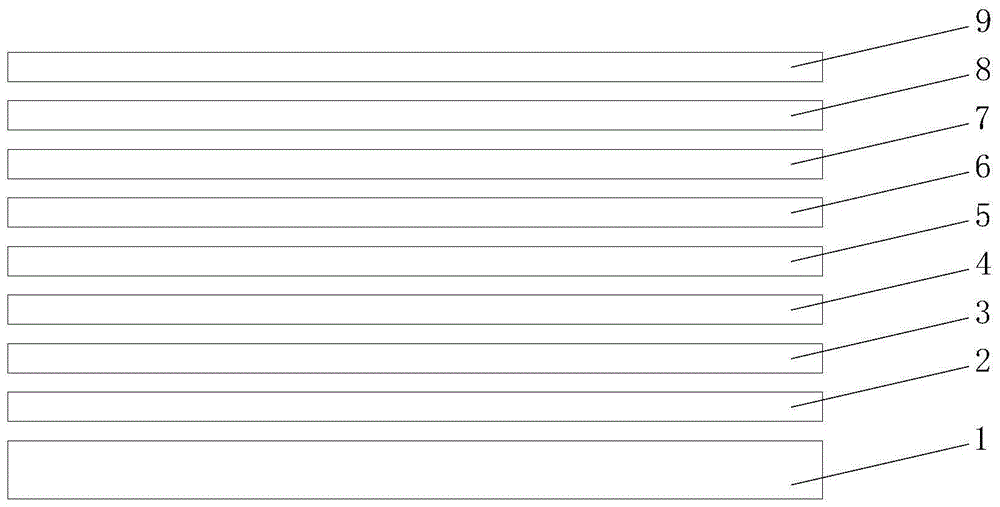

[0065] When the substrate 1 is formed of resin, the manufacturing method specifically includes the following steps:

[0066] 1) Cleaning and drying the substrate 1;

[0067] 2) Coating the outer surface of the substrate 1;

[0068] A. Plating the first film layer 2:

[0069] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 50-70 ℃, bombard the film material of the first film layer 2 with an electron gun, the film material of the first film layer 2 is evaporated and deposited on the outer surface of the substrate in the form of nano-scale molecules At the same time, the evaporation rate of the first film layer 2 is controlled to be 2.5? / S, and the thickness of the first film layer 2 after the final formation is 10-100 nm; wherein, the film material of the first film layer 2 is titanium pentoxide , forming a titanium pentoxide layer;

[0070] B. Plating the second film l...

Embodiment 2

[0086] When the substrate 1 is formed from glass, the manufacturing method specifically includes the following steps:

[0087] 1) Cleaning and drying the substrate 1;

[0088] 2) Coating the outer surface of the substrate 1;

[0089] A. Plating the first film layer 2:

[0090] Adjust the vacuum degree in the vacuum coating chamber to less than or equal to 5.0×10 -3 Pa, and control the temperature in the vacuum coating chamber to 200-300 ℃, bombard the film material of the first film layer 2 with an electron gun, the film material of the first film layer 2 is evaporated and deposited on the outer surface of the substrate in the form of nano-scale molecules At the same time, the evaporation rate of the first film layer 2 is controlled to be 2.5? / S, and the thickness of the first film layer 2 after the final formation is 10-100 nm; wherein, the film material of the first film layer 2 is titanium pentoxide , forming a titanium pentoxide layer;

[0091] B. Plating the second fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com