Fischer Tropsch synthesis catalyst for preparing heavy hydrocarbon product through synthesis gas and preparation method of catalyst

A Fischer-Tropsch synthesis and catalyst technology, applied in the field of preparation of Fischer-Tropsch synthesis catalysts, can solve the problems of limited diffusion of reactants and products, low selectivity of heavy hydrocarbons, and high selectivity of methane, and achieve good selectivity of heavy hydrocarbons , the effect of low methane selectivity and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A Fischer-Tropsch synthesis cobalt-based catalyst for producing heavy hydrocarbon products from synthesis gas, the steps of its preparation method are as follows:

[0051] (1) Preparation of mesoporous nano-silica spheres:

[0052] Add 4.59g of cetyltrimethylammonium bromide and 0.45g of diethanolamine into a three-necked flask filled with 238mL of distilled water, and stir at 40°C for 1 hour; then add 34.67g of tetraethylorthosilicate and continue stirring 2h; after the end, filter and wash, then dry at 120°C for 12h, and finally bake at 550°C for 6h to obtain white powdery mesoporous nano-silica beads, marked as Z1.

[0053] It is measured that the particle diameter of the mesoporous nano-silica sphere Z1 is 20-50 nm.

[0054] (2) Preparation of catalyst:

[0055] 2.74gCo(NO 3 ) 2 ·6H 2 O was dissolved in 27.4mL of water, then 2.74mL of ammonia water (7mol / L) was added under stirring, and after stirring for 20min, the resulting suspension was transferred to a 100...

Embodiment 2

[0063] A Fischer-Tropsch synthesis cobalt-based catalyst for producing heavy hydrocarbon products from synthesis gas, the steps of its preparation method are as follows:

[0064] (1) Preparation of mesoporous nano-silica spheres:

[0065] With embodiment 1.

[0066] (2) Preparation of catalyst:

[0067] 4.36gCo(NO 3 ) 2 ·6H 2 O was dissolved in 43.60mL of water, and then 4.36mL of ammonia water (7mol / L) was added under stirring. After stirring for 20min, the obtained suspension was transferred to a 100mL autoclave, and the mesoporous nano 5.0g of silica pellets, kept at 160°C for 5h, cooled to room temperature, dried by rotary evaporation and then washed, then dried at 120°C for 12h and calcined at 350°C for 4h to obtain cobalt-based catalyst S2: 15Co / SiO 2 , wherein 15 represents that the weight percent content of cobalt element in the catalyst is 15%.

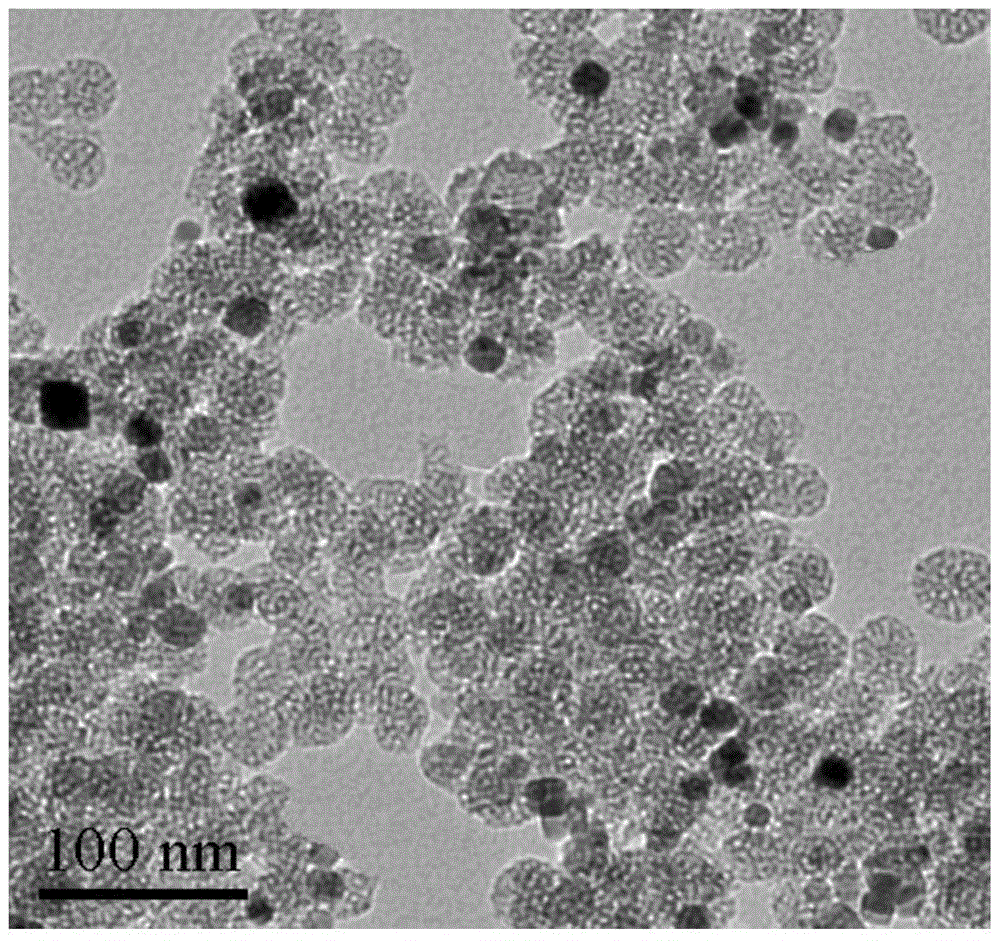

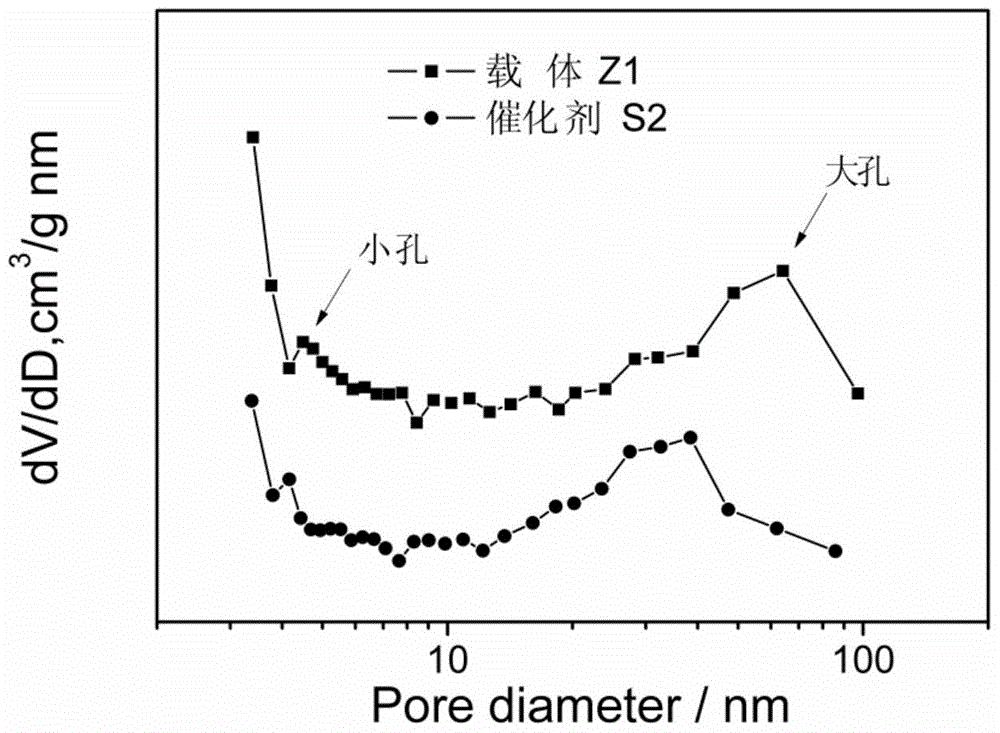

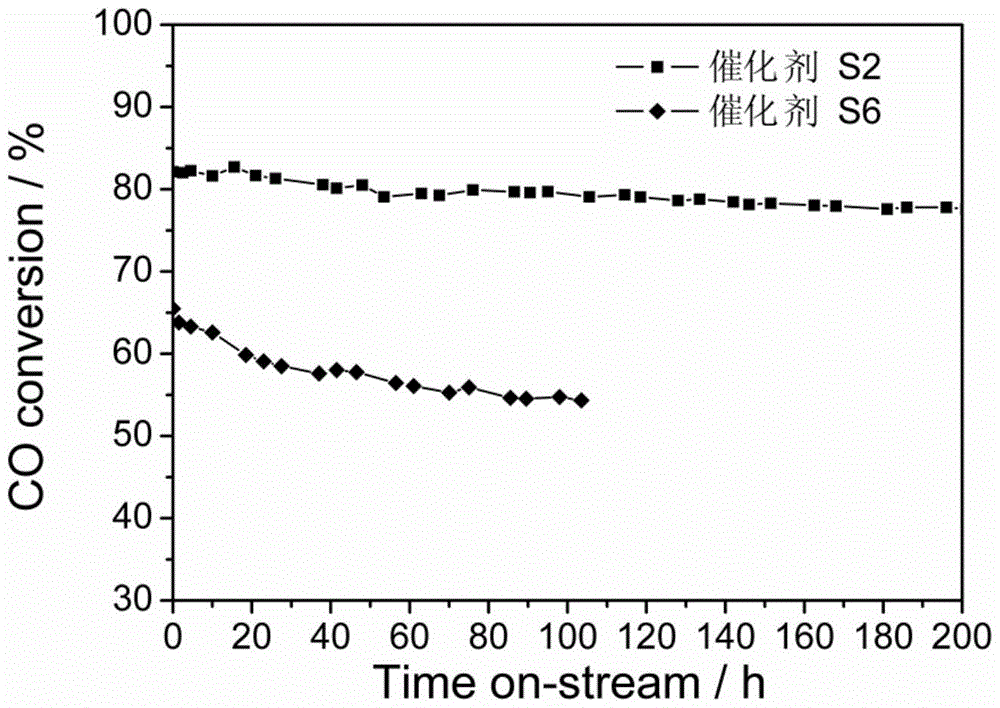

[0068] From the transmission electron microscope image ( figure 1 ), it can be seen that the diameter of the mesopor...

Embodiment 3

[0072] A Fischer-Tropsch synthesis cobalt-based catalyst for producing heavy hydrocarbon products from synthesis gas, the steps of its preparation method are as follows:

[0073] (1) Preparation of mesoporous nano-silica spheres:

[0074] With embodiment 1.

[0075] (2) Preparation of catalyst:

[0076] 10.58gCo(NO 3 ) 2 ·6H 2 O was dissolved in 105.80mL of water, then 10.58mL of ammonia water (7mol / L) was added under stirring, and after stirring for 20min, the resulting suspension was transferred to a 100mL autoclave, and the mesoporous nano 5.0g of silica pellets, kept at 160°C for 5h, cooled to room temperature, dried by rotary evaporation, then dried at 120°C for 12h and calcined at 350°C for 4h to obtain the cobalt-based catalyst S3: 30Co / SiO 2 , wherein 30 means that the weight percent content of cobalt element in the catalyst S3 is 30%.

[0077] After testing, there are mesoporous pores with a diameter ranging from 2 to 5 nm on the mesoporous nano-silica spheres i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com