A kind of preparation method of propane oxidative dehydrogenation to propylene catalyst

An oxidative dehydrogenation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, molecular sieve catalysts, etc. It can avoid further oxidation, improve the conversion rate and selectivity of propylene, and reduce the cost of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

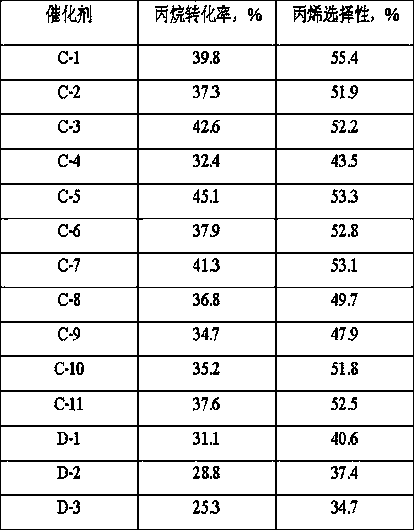

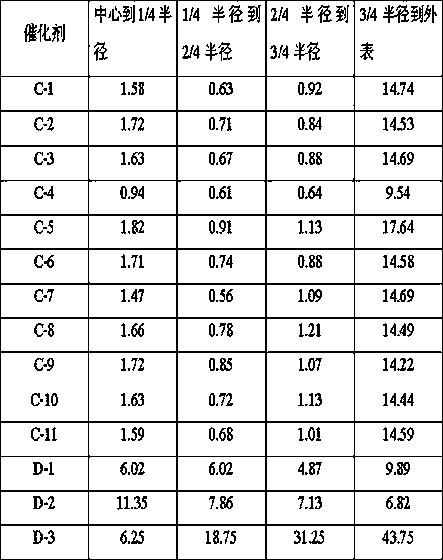

Examples

Embodiment 1

[0027] Weigh 2.97g of nickel nitrate and 0.55g of ammonium tungstate and dissolve them in an appropriate amount of deionized water to obtain solution A; use the equal volume impregnation method to load 20g of alumina (pore volume is 0.72ml / g, specific surface area is 242m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to obtain catalyst precursor B, wherein Ni accounted for 3% of the weight of the carrier by element, and W by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450 ° C, 0.2 MPa (absolute pressure), and the reduction time is 4 hours; after the reduction activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrog...

Embodiment 2

[0029] Weigh 2.97g of nickel nitrate and 0.55g of ammonium tungstate and dissolve them in an appropriate amount of deionized water to obtain solution A; use the equal volume impregnation method to load 20g of silicon oxide (pore volume 1.06ml / g, specific surface area 387m 2 / g, spherical, equivalent diameter 0.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to obtain catalyst precursor B, wherein Ni accounted for 3% of the carrier weight by element, and W accounted for The weight of the carrier is 2%; the catalyst precursor B is activated in a mixed atmosphere containing hydrogen. Catalyst precursor B and 300mL sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced with hydrogen for 3 times, then adjusted the hydrogen pressure to 3MPa, and reacted at 220°C for 4h; The final mixture was placed for 2h, filtered, and the resulting solid sample was dried at room temperature until there w...

Embodiment 3

[0031] Weigh 2.97g of nickel nitrate and 0.55g of ammonium tungstate and dissolve them in an appropriate amount of deionized water to obtain solution A; use an equal volume impregnation method to load 20g of SBA-15 (the pore volume is 1.23ml / g, and the specific surface area is 701m 2 / g, strip shape, equivalent diameter 1.5mm) carrier, aged at room temperature for 4h, dried at 80°C for 12h, and calcined at 700°C for 4h to obtain catalyst precursor B, wherein Ni accounted for 3% of the weight of the carrier by element, and W by element Accounting for 2% of the weight of the carrier; catalyst precursor B is activated in a mixed atmosphere containing hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450 ° C, 0.2 MPa (absolute pressure), and the reduction time is 4 hours; after the reduction activation The catalyst precursor B and 300mL of sorbitol solution with a mass concentration of 10% were added to the autoclave, sealed and replaced w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com