Preparation method of au nanomaterial/au-metal oxide nanocomposite material

A nanocomposite material and nanomaterial technology, applied in the field of preparation of Au nanomaterial/Au-metal oxide nanocomposite material, can solve the problems of difficult size control, wide particle size distribution, harmfulness, etc., and achieve narrow particle size distribution, Low specific surface tension, anti-agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

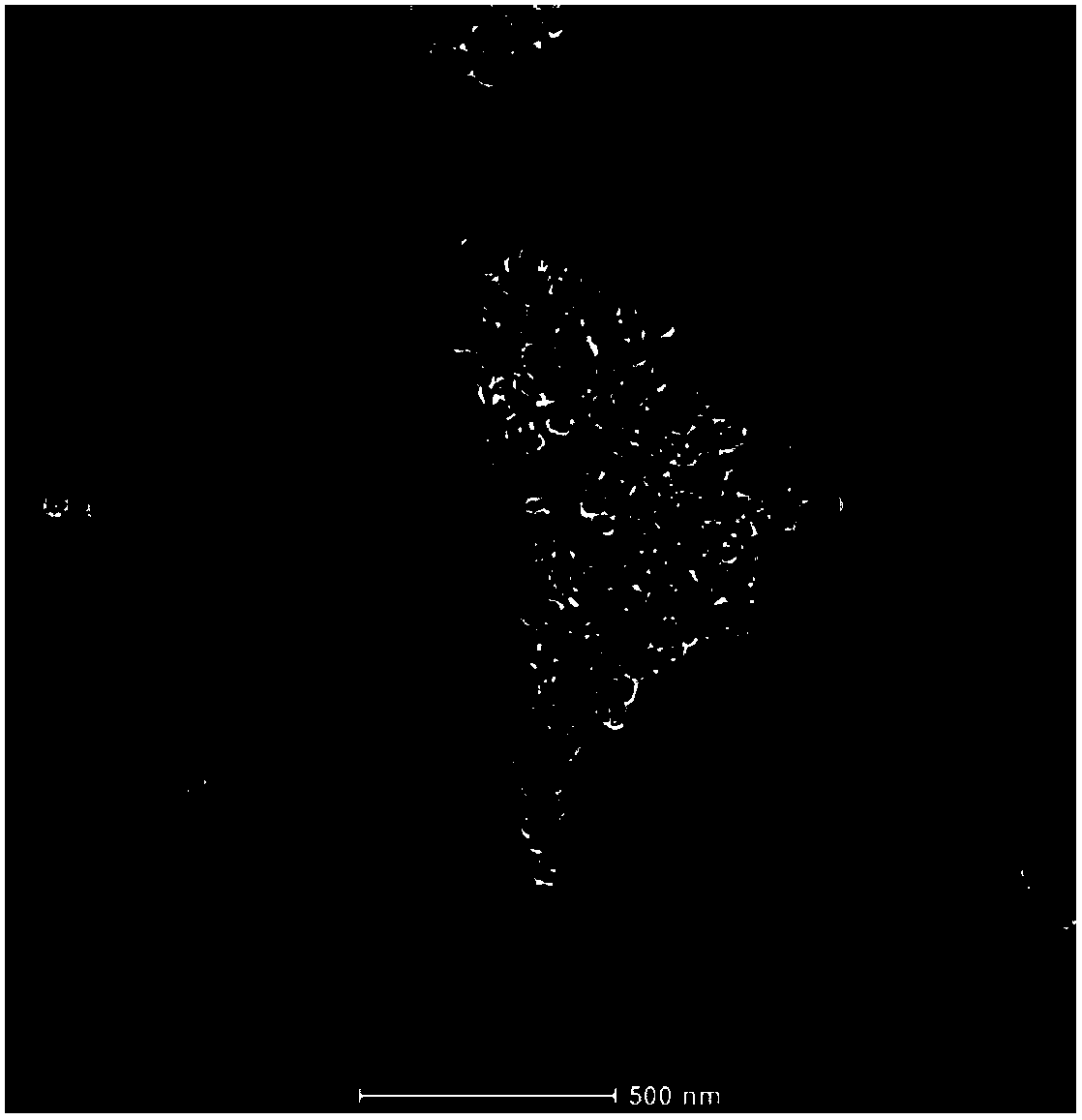

Embodiment 1

[0052] A preparation method of Au nanomaterials, comprising the steps of:

[0053] 1. Preparation of chloroauric acid ethanol solution:

[0054] a. Add 1g of chloroauric acid (HAuCl 4 4H 2 O) dissolved in 600mL absolute ethanol (mass percentage is 0.21%), set aside.

[0055] 2. Preparation of sodium citrate ethanol sol:

[0056] b. 40g sodium citrate dihydrate (Na 3 C 6 h 5 o 7 2H 2 O) Dissolve in 20 mL of 50° C. deionized water (66.7% by mass), stir well for 20 min, and set aside.

[0057] c. Prepare 50mL of absolute ethanol in a beaker, stir vigorously with a magnetic stirrer, and the stirring speed is greater than 1000rpm.

[0058] d. In the state of vigorous stirring, slowly drop the sodium citrate aqueous solution prepared in the first step into absolute ethanol with a 3mL dropper. 10 drops (about 0.2 mL) were dropped into every 50 mL of absolute ethanol solution to prepare sodium citrate ethanol sol solution. Repeat 4 times to obtain a total of 200 mL sodium c...

Embodiment 2

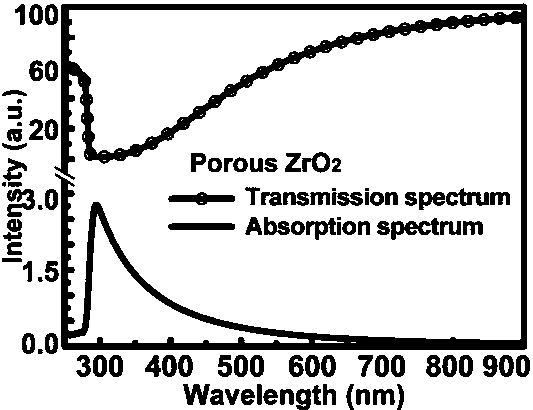

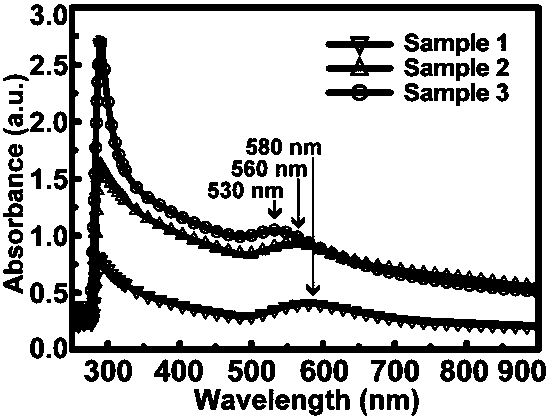

[0066] A gold-ZrO 2 A method for preparing a nanocomposite material, comprising the steps of:

[0067] 1. Preparation of chloroauric acid ethanol solution:

[0068] a. Add 1g of chloroauric acid (HAuCl 4 4H 2 O) dissolved in 600mL absolute ethanol (mass percentage is 0.21%), set aside.

[0069] 2. Preparation of sodium citrate ethanol sol:

[0070] b. 40g sodium citrate dihydrate (Na 3 C 6 h 5 o 7 2H 2 O) Dissolve in 20 mL of 50° C. deionized water (66.7% by mass), stir well for 20 min, and set aside.

[0071] c. Prepare 50mL of absolute ethanol in a beaker, stir vigorously with a magnetic stirrer, and the stirring speed is greater than 1000rpm.

[0072] d. In the state of vigorous stirring, slowly drop the sodium citrate aqueous solution prepared in the first step into absolute ethanol with a 3mL dropper. 10 drops (about 0.2 mL) were dropped into every 50 mL of absolute ethanol solution to prepare sodium citrate ethanol sol solution. Repeat 4 times to obtain a tot...

Embodiment 3

[0085] A gold-ZrO 2 A method for preparing a nanocomposite material, comprising the steps of:

[0086] 1. Preparation of chloroauric acid ethanol solution:

[0087] a. Add 1g of chloroauric acid (HAuCl 4 4H 2 O) dissolved in 600mL absolute ethanol (mass percentage is 0.21%), set aside.

[0088] 2. Preparation of sodium citrate ethanol sol:

[0089] b. 40g sodium citrate dihydrate (Na 3 C 6 h 5 o 7 2H 2 O) Dissolve in 20 mL of 50° C. deionized water (66.7% by mass), stir well for 20 min, and set aside.

[0090] c. Prepare 50mL of absolute ethanol in a beaker, stir vigorously with a magnetic stirrer, and the stirring speed is greater than 1000rpm.

[0091] d. In the state of vigorous stirring, slowly drop the sodium citrate aqueous solution prepared in the first step into absolute ethanol with a 3mL dropper. 10 drops (about 0.2 mL) were dropped into every 50 mL of absolute ethanol solution to prepare sodium citrate ethanol sol solution. Repeat 4 times to obtain a tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com