Method of preparing hollow mesoporous zirconium dioxide through sol-gel protective method

A technology of zirconia and protection method, which is applied in the field of preparation of hollow mesoporous zirconia, which can solve the problems of poor stability and easy breakage of mesoporous zirconia materials, and achieve the effect of regular shape and corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

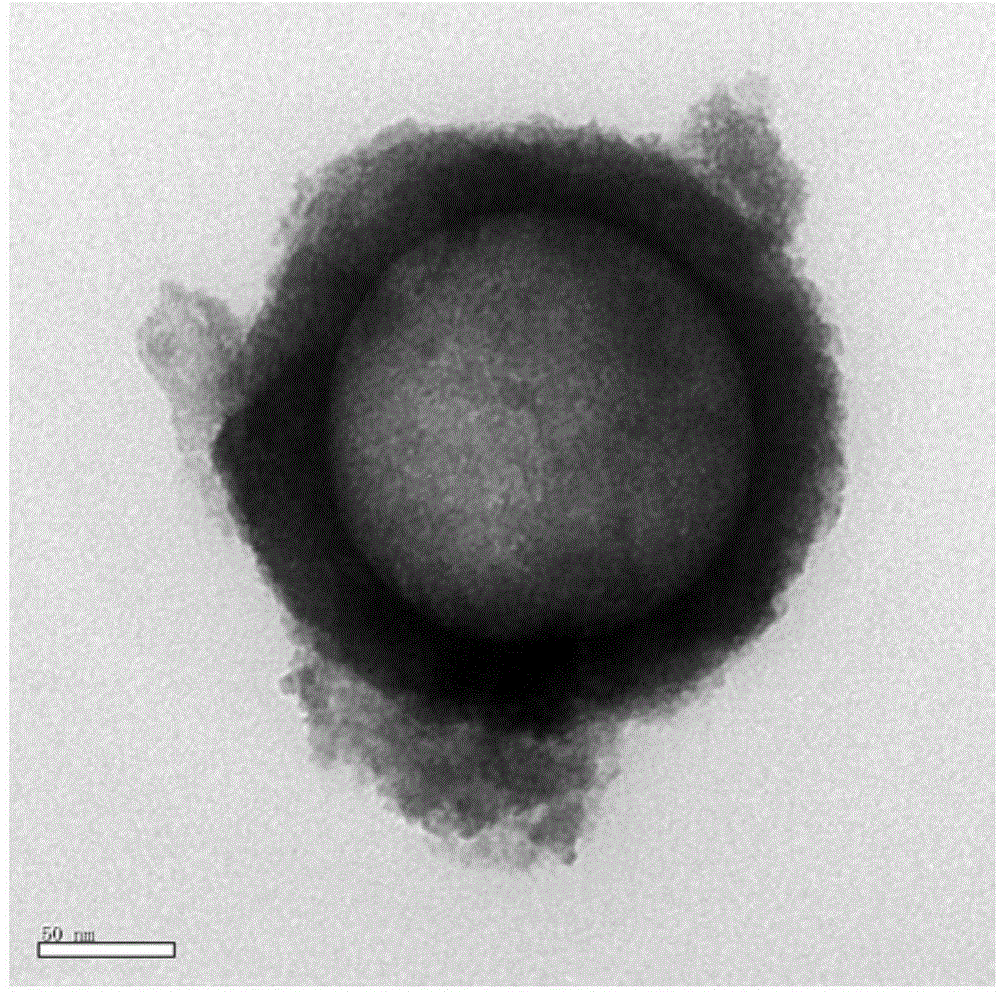

[0022] Example 1: 44mL ethanol, 2mL ammonia water, and 9mL water were stirred at 30°C and 300rpm for 30 minutes, then added 4mLTEOS, reacted for 8 hours, centrifuged, washed with water and ethanol to obtain monodisperse SiO with a thickness of about 100nm 2 Microspheres; the product is dispersed in 180mL of ethanol, at 30°C, at a speed of 400rpm, add 0.3mL of Brij30, 0.3mL of water and 1.3mL of zirconium n-butoxide, react for 8h, centrifuge, wash with water, the product is dispersed in 40mL of water, and aged for 12h Disperse the product in 80mL of water, add 0.15g of PVP at 400rpm, react for 24h, centrifuge, wash with ethanol; disperse the appeal product in 44mL of ethanol, 2mL of ammonia water, 9mL of water at 30°C and 300rpm, stir for 30min, Add 4mLTEOS, react for 8h, centrifuge, wash with water and ethanol to obtain monodisperse SiO 2 ZrO 2 SiO 2 Particles; calcined at 600°C for 5h; the above product was denucleated with an aqueous solution of NaOH, centrifuged, washed, ...

Embodiment 2

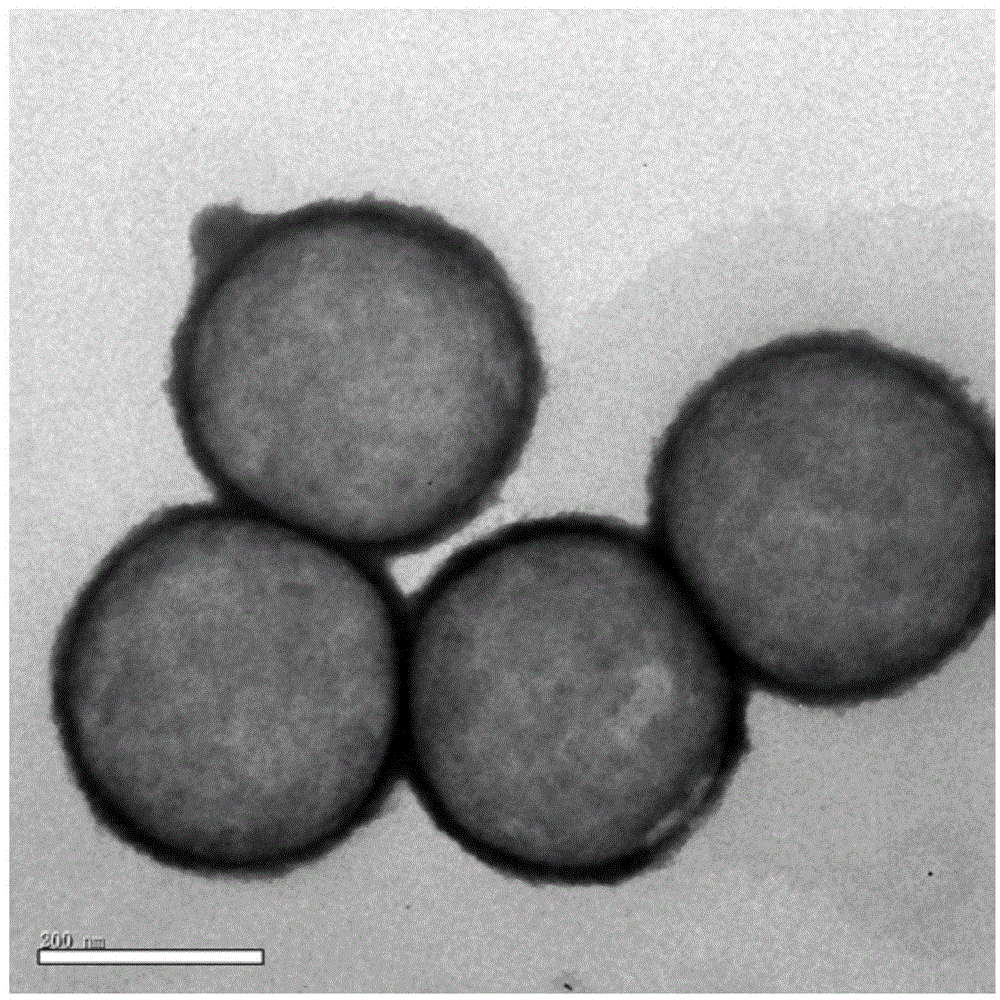

[0023] Example 2: 75mL ethanol, 5.13mL ammonia water, and 8mL water were stirred at a temperature of 30°C and a speed of 300rpm for 30 minutes, then 6mLTEOS was added, reacted for 8h, centrifuged, washed with water and ethanol to obtain monodisperse SiO of about 300nm 2 Microspheres; the product is dispersed in 180mL ethanol, at 30°C and 400rpm, add 0.5mL Brij30, 0.5mL water and 1.5mL zirconium n-butoxide, react for 8h, centrifuge, wash with water, disperse the product in 40mL water, and age for 12h Disperse the product in 80mL of water, add 0.15g of PVP at 400rpm, react for 24h, centrifuge, wash with ethanol; disperse the product in 75mL of ethanol, 5.13mL of ammonia water, 8mL of water at 30°C and 300rpm, stir for 30min , add 6mLTEOS, react for 8h, centrifuge, wash with water and ethanol to get monodisperse SiO 2 ZrO 2 SiO 2 Particles; calcined at 600°C for 5h; the above product was denucleated with an aqueous solution of NaOH, centrifuged, washed, and dried to obtain mono...

Embodiment 3

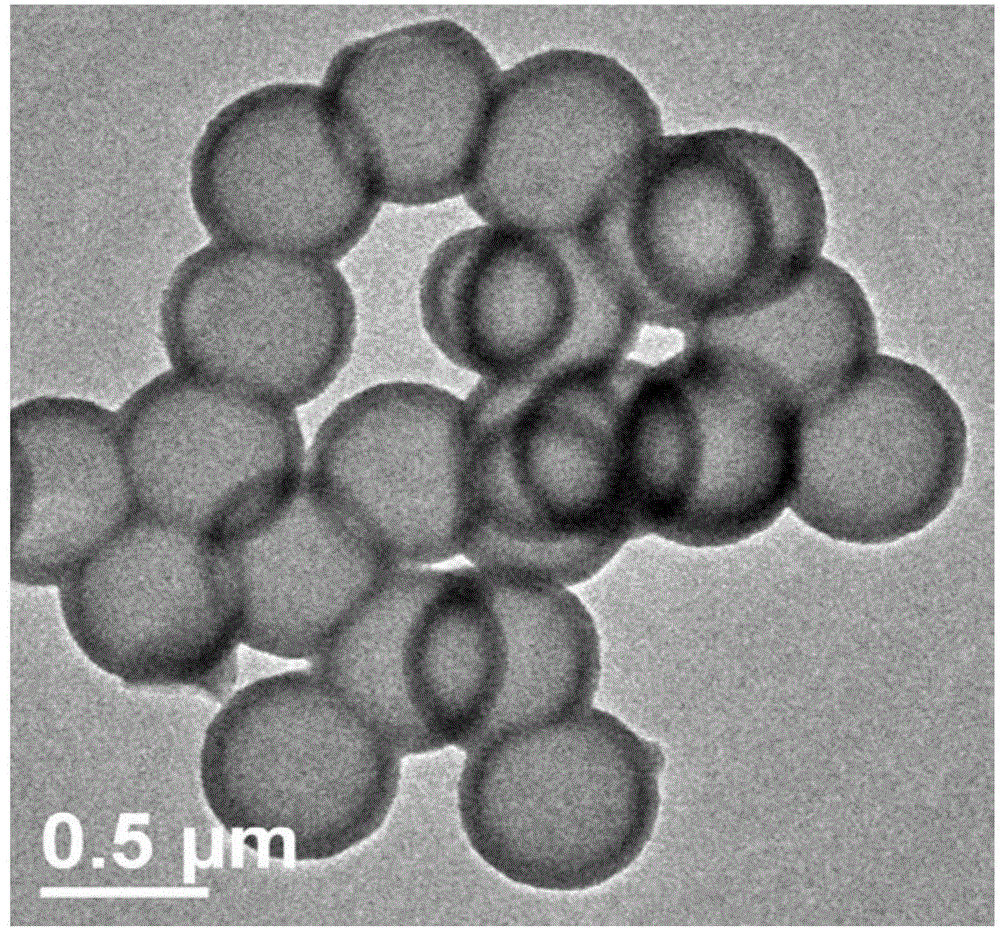

[0024] Example 3: 91mL ethanol, 32.5mL ammonia water, at a temperature of 30°C and a speed of 300rpm, after stirring for 30min, add 5.5mLTEOS, react for 1h, centrifuge, wash with water and ethanol to obtain monodisperse SiO of about 500nm 2 Microspheres; the product is dispersed in 175mL ethanol, at 30°C and 400rpm, add 0.13mL Brij30, 0.13mL water and 1.0mL zirconium n-butoxide, react for 8h, centrifuge, wash with water, disperse the product in 40mL water, and age for 12h Disperse the product in 80mL of water, add 0.15g of PVP at 400rpm, react for 24h, centrifuge, wash with ethanol; disperse the product in 75mL of ethanol, 5.13mL of ammonia water, 8mL of water at 30°C and 300rpm, stir for 30min , add 3mLTEOS, react for 8h, centrifuge, wash with water and ethanol to get monodisperse SiO 2 ZrO 2 SiO 2 Particles; calcined at 600°C for 5h; the above product was denucleated with an aqueous solution of NaOH, centrifuged, washed, and dried to obtain monodisperse hollow mesoporous z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com